616.13 Work Zone Capacity, Queue and Travel Delay

When lane closures are required for road construction, rehabilitation, or maintenance activities, the capacity of the roadway may be greatly reduced. Capacities differ for interstates, freeways, multiple-lane routes and two-lane roadways due to the number of closed lanes, how the project will affect the surrounding roadways, and geometrics of the roadway. When the reduction is too great the traveling public may experience unacceptable travel delays through the work zone, vehicles queuing (a line of vehicles) upstream of the work zone and possible frustration of the motorist.

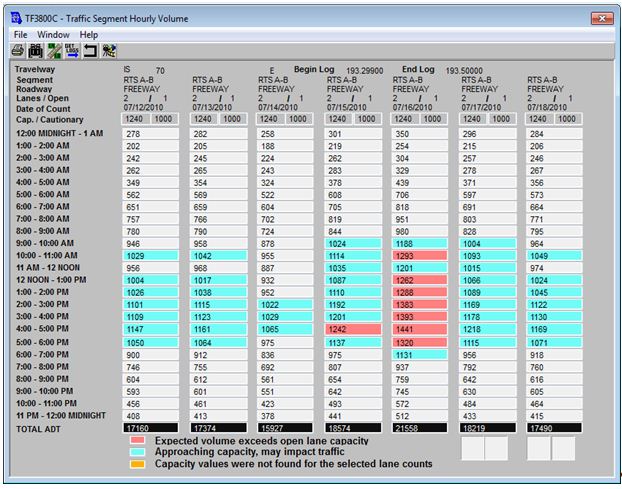

Typical estimation for capacity restriction is outlined in the MoDOT Work Zone Guidelines. To help MoDOT personnel view capacity restrictions and cautionary zones, the Transportation Management System (TMS) provides the restrictions in a color coded Traffic Segment Hourly Volume (TSHV) table. Directions of how to use the TSHV table are available.

The TSHV table provides time periods when lane closures are in a cautionary zone or a capacity restriction, which are color coded blue and red, respectively.

The cautionary zone is a triggering point for a review of the location or area the work will be performed. Normally, there should not be a capacity or travel delay concern, but due to history, narrow lanes, climbing grades, etc., the capacity may be reduced to a level of concern for delays or queuing. If there is a queuing or delay concern, work may be required to be performed during off-peak hours (i.e., nighttime and/or weekends) when necessary.

When the hourly volume reaches the capacity restriction level, work should be scheduled during off-peak hours. Off-peak hours could consist of the time between rush-hour, per example; some locations only work between the hours of 9 am and 3pm. Many locations are taking advantage of nighttime or weekend hours due the lower volume of traffic.

Due to different types of work, there may be times when lane closures are necessary during the hours exceeding the Capacity Restriction levels. The TSHV table does not provide information about possible delays or queuing of traffic due to capacity restrictions.

Over the years, software programs have been developed to estimate the length of vehicles queued upstream from the work zone taper. The queue length is normally calculated in miles. The queue length is based on the number of vehicles in the number of open lanes upstream of the work zone taper. These software programs may also provide an estimate of travel delays in minutes.

The MoDOT Work Zone Impact Analysis Spreadsheet can help planners, designers, consultants, construction inspectors, contractor work zone specialists and maintenance personnel estimate queuing and traffic delays.

616.13.1 Urban and Rural Significant Projects with Major Surrounding Network Systems

Depending on the location and duration, urban and rural significant projects may entail an in-depth analysis of the surrounding network of roads. Due to the complexity, project analysis of these larger projects should start as early in the planning phase as practical. With early analysis, the planner or designer can make an appropriate cost estimate for traffic management to the early budget requests and the appropriate temporary traffic control devices to mitigate possible traffic concerns. Various traffic analysis tools and techniques can be utilized to evaluate these situations. The district Traffic offices should be able to help determine an appropriate analysis methodology and support any technical analysis to determine the potential work zone impacts.

616.13.2 Interstate, Freeways and Multi-lane Roadways

Due to MoDOT’s large highway system, interstate, freeway, and multi-lane work zones may be located anywhere from the rural and urban areas to the flat and hilly terrain. Normally, these roadways have larger volumes and higher speed limits. When volumes exceed the capacity restriction level, ideally work should be performed when the volumes are lower, such as, off-peak, nighttime, weekends, etc. However, there are times when work has to be performed through the capacity restriction time periods, due to the type of work, longevity of the project, etc. Whenever a lane closure is performed during the capacity restriction time period, a potential for queuing and delays may occur. To assist the planner, designer, construction inspector, contractor work zone specialist, and maintenance personnel, the University of Missouri-Columbia has helped developed a user-friendly software program, MoDOT Work Zone Impact Analysis Spreadsheet, to provide an estimate of queues and delays to the traveling public.

For contract projects, work zone capacity should be analyzed early in the planning and design stages so enough time will be provided for designing the work zone and budgeting for possible use of advance warning strategies.

For maintenance projects, history may have shown locations that do not queue or delay due to the type and location of work, percentage of trucks, etc. If the work area has not shown queue and delays, the spreadsheet analysis may not be warranted.

MoDOT Work Zone Impact Analysis Spreadsheet

To provide user friendly features, the spreadsheet uses an excel database program, which requires a limited amount of data from the user. The spreadsheet has color-coded (blue, orange and yellow) fields that require information which can be obtained from the TMS database.

The WZ Impact Analysis Spreadsheet Directions provides guidance on how to use the spreadsheet.

The spreadsheet consists mainly of two parts: existing conditions and work zone details. When calculating the capacity of the work zone, the program accounts for different factors that affect the capacity (ex. location of workers and/or equipment to the travel lane, travel lane width, and number of trucks). The spreadsheet is used to calculate the queue lengths, delay of travel, and cost of the travel delay based on the estimated capacity.

616.13.2.1 Work Location

Studies have shown that the location of the physical work (workers/equipment) to the traveling public may adjust the base work zone capacity (1600 passenger car/hour/lane) as much as ±10%. The MoDOT Work Zone Impact Analysis Spreadsheet provides capacity based on worker/equipment locations, worker protection, or moving traffic away from the work area (ramp by-pass, crossover on divided highway).

616.13.2.2 Travel Lane Width

Reducing the travel lane width will reduce the free-flow speed, which will cause a decrease capacity through the work zone. Currently, speeds are not used to estimate capacity within the work zone, but an adjustment factor is used to calculate the capacity based on the different lane widths. The MoDOT Work Zone Impact Analysis Spreadsheet includes a reduction factor based on the travel lane width.

616.13.3 Capacity Restriction for Different Climbing Grades

Interstate, freeway and multi-lane roadways with a continuous climbing grade may reduce the work zone roadway capacity, especially when large percentages of heavy vehicles (trucks, buses, RV, etc.) are present. If the grades are steep and long enough, the heavier vehicles speed may be reduce to a “crawl” speed.

Due to the length and weight of the larger vehicles, they cannot be compared with passenger vehicles (cars/small trucks). Large vehicles are normally calculated as equivalent trucks. In Table 616.13.3, large vehicles are measured as a "Passenger-Car Equivalents for Trucks" that would be equal to a large vehicle based on length of grade, percent of grade and percentage of large vehicles. Table 616.13.3 was developed to easily estimate the equivalent trucks in the MoDOT Work Zone Impact Analysis Spreadsheet. The necessary data needed for the estimate Passenger-Car Equivalents for Trucks are climbing grades, length of the grade, and percent of trucks.

Table 616.13.3 Passenger-Car Equivalents for Trucks on Upgrades

| Climbing Grade (%)1 | Length (mi.) | ET, Passenger-Car Equivalents for Trucks on Upgrades | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Percentage of Trucks | |||||||||||||

| 2 | 4 | 5 | 6 | 8 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | ||

| ≤ 2 | - | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| >2-3 | 0 - 0.49 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| 0.50 - 1.00 | 2.0 | 2.0 | 2.0 | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| >1.00 | 3.0 | 3.0 | 2.5 | 2.5 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | |

| >3-4 | 0 - 0.49 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| 0.50 - 1.00 | 3.0 | 3.0 | 2.5 | 2.5 | 2.5 | 2.5 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | |

| >1.00 | 4.0 | 3.5 | 3.0 | 3.0 | 3.0 | 3.0 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| >4-5 | 0 - 0.49 | 3.0 | 2.5 | 2.5 | 2.5 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| 0.50 - 1.00 | 4.0 | 3.5 | 3.5 | 3.5 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | |

| >1.00 | 5.0 | 4.0 | 4.0 | 4.0 | 3.5 | 3.5 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | |

| >5-6 | 0 - 0.49 | 4.5 | 4.0 | 3.5 | 3.0 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| 0.50 - 1.00 | 5.5 | 5.0 | 4.5 | 4.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | |

| >1.00 | 6.0 | 5.0 | 5.0 | 4.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | |

| >6 | 0 - 0.49 | 5.0 | 4.5 | 4.0 | 4.0 | 3.5 | 3.0 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| 0.50 - 1.00 | 6.0 | 5.5 | 5.0 | 5.0 | 4.5 | 4.0 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | |

| >1.00 | 7.0 | 6.0 | 5.5 | 5.5 | 5.0 | 4.5 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | |

| 1 Climbing Grade can be located anywhere throughout the entire work zone project. | |||||||||||||

| Note: An example of the table is shown above. To locate the Equivalent Truck value of 1.5 (shown in green) with the following criteria: grade of 3.5%, length is shorter than ½ mile and 30% trucks (all shown in blue). | |||||||||||||

616.13.4 Capacity Guidelines for Ramps

Ramps located near work zones may disrupt traffic flow due to the interaction of traffic entering or exiting the on/off ramps.

MoDOT’s spreadsheet does not address individual ramps. If the work zone is located 500 ft. upstream or downstream of the on/off ramps, the TMS hourly volume should be based on the highest upstream or downstream volumes from the ramp.

Closing ramps may be an option to reduce the volume into the work zone, which may relieve queuing and delay concerns. When closing ramps, the traveling public should have a detour route.

616.13.5 Travel Delay or Travel Time

On interstate and other major roadway or bridge projects, near real-time travel time will be provided for work zones subject to traffic delays of 10 minutes or more due to work activity. Travel delay or increased travel time may be calculated within the different work zone software. There may be times that queue lengths and travel delays develop on projects that were not calculated within the software programs.

When delays occur in the field, delay time will be calculated by the following equation:

- Delay Time = Twz - Tp

- Where:

- Twz = Time to travel through WZ

- Tp = Time to travel through area at posted WZ speed limit

Project personnel will determine these travel times and update DMS/CMS messages, as needed, at regular intervals and as conditions change. Possible methods to estimate travel times include:

- driving the limits of the work zone,

- establishing times based on predetermined queue lengths,

- monitoring travel times of vehicles traveling through the work zone or

- automated means.

The spreadsheet, Travel Time for Work Zones, calculates the delay time within the advance warning area or the activity area (buffer and work space and end taper). You are invited to field test Travel Time for Work Zones and forward your comments to Traffic Division – Work Zone Section (573) 526-0123 or (573) 526-4329.

616.13.6 Strategies for Advance Warning

Below are several examples of strategies to inform the public or reduce work zone queues and delays, but they are not all inclusive.

616.13.6.1 Temporary Traffic Control Devices

Proper set-up of the temporary traffic control (TTC) devices is designed to provide the maximum safety and mobility through a work zone. Through the years, studies have been conducted to design the different components of the work zone. There are times (geometrics of roadway, etc.) when the work zone may have the speed limit reduced, but the amount of spacing and location of the TTC devices should be based on the posted speed limit (before the work zone).

616.13.6.2 Changeable Message Signs (CMS) and Dynamic Message Signs (DMS)

CMS are portable signs and DMS are stationary signs both of which are capable of displaying several messages in a sequence and display pertinent traffic operational and guidance information as well as advising drivers of unexpected work zone traffic and routing conditions.

CMS and/or DMS depending on the location may alleviate driver frustration with queues and delays by informing the traveling public with pertinent information.

When used, distance to end of work zone, in miles, with estimated travel times, in five-minute increments, will be displayed on a properly delineated CMS or DMS board. These boards will be located in advance of any potential traffic queue. Additional boards may be used as needed. The recommended display for these messages is as follows:

Unless travel time is provided through automated means, CMS and DMS boards will display the following recommended messages when workers are not present and traffic delay can be expected.

CMS and DMS boards may display meaningful messages when workers are not present, no traffic delay can be expected, and travel time is not provided through automated means.

When needed, commission-owned CMS and DMS units should be used unless justified otherwise. The core team should review the districts quantity of CMS boards to verify the district’s ability to supply the project before plans are finalized.

616.13.6.3 Work Zone Intelligent Transportation Systems (WZITS)

Through the years, the advancement of technology has produced work zone intelligent transportation systems (WZITS) that can provide real-time data to the traveling public.

Instead of having a person being present to change the CMS or DMS through notification, the WZITS may be equipped with sensors, communication technology, computers, internet connection, etc. This technology can collect traffic volume, speed, etc. and then provide the traveling public with the accurate and real-time information for that particular work zone.

The nonstandard Work Zone Intelligent Transportation System special provision is available as a guide for use in a project.

The WZITS can provide travel time, travel delay, congestion concerns, speed advisory information, etc. Minnesota Department of Transportation (MnDOT) and American Traffic Safety Services Association (ATSSA) have the following documents that describe installation and use of the different WZITS products.

MnDOT and ATSSA examples show the use of either CMS boards or static signs. The use of static signs with lights or small displays may save significant saving compare to using contractor furnished CMS boards, but the CMS board can be readily moved to different locations. If MoDOT has adequate number CMS boards with the capabilities to be used on projects, rental saving could be offset. The district core team should review the CMS quantities to verify the district’s ability to supply the project before plans are finalized.

The Central Office Traffic Division Work Zone section is available as a resource for the use of the WZITS technology.

616.13.6.4 Designated Detour or Relief Route

A project with a designated detour or relief route, when queuing occurs, may provide enough relief to handle the capacity restrictions of a work zone. Over the years, districts have used different strategies of lane reliefs by taking all vehicles or making a separation of light vehicles versus heavy vehicles on the detour or relief routes.

Studies have shown that a typical project may have 5-10 percent of the traffic volume using the detour or relief route on their own initiative. With active guidance (MoDOT personnel, law enforcement, etc.) the detour or relief route volume may be increased. Even though the detour or relief route volume is small, it may be enough to relieve the congestion and allow free-flow traffic.

616.13.6.5 Maintain Same Number of Lanes

For some projects, the capacity of the roadway can be restructured by maintaining the same number of lanes by reducing the lane and/or the shoulder widths.

Depending on the project scope, project duration and traffic delay and impact, adding a lane or improving a shoulder could be an option for a project to reduce the capacity concerns of the roadway. These decisions should be made early in the planning or design stages, so funds can be designated for this particular enhancement.

Projects with the same number of lanes, in general, provide the same capacity as before the project, which may significantly reduce or eliminate queuing and travel delays.

616.13.6.6 Public Information

Public information (PI) is an important component of transportation management plan within work zones. PI may range in complexity depending on the project location, scope and duration. For example, two projects ranging from a smaller project in the rural area to an urban area or interstate project.

- Rural: Place the information on the Traveler Information Map, CMS board, local newspaper and radio station a week or two prior to the start of the project, etc.

- Urban: Place the information on the Traveler Information Map, several media outlets (newspapers, radio stations, television), contact Motor Carrier Service to contact different trucking companies, brochures, CMS/DMS prior to the start and throughout the project, incident response, etc.

The ultimate goal is to provide the earliest information of any congestion concerns to the public, so the travelers can adjust their travel times in an effort to reduce the queuing and delay.

616.13.7 Traffic Pacing

| Traffic Pacing Worksheet |

| Staging Plan Details (Mainline Pacing Details) |

| Traffic Pacing Changeable Message Signs Layout |

Traffic pacing is a traffic control technique that facilitates short duration overhead work operations by pacing traffic at a safe slow speed for a predetermined distance upstream of the work area, rather than being completely stopped. The pacing of vehicles shall be controlled by pilot vehicles (law enforcement vehicles with blue lights flashing) driven by uniformed law enforcement personnel. Any on-ramps or other access points between the beginning point of the pacing area and the work area shall be blocked until the pilot vehicles have passed. Two-way radios shall be used to provide constant communication between the pilot vehicles, contractor’s workers, and the project engineer. Advanced signing warning motorists of the traffic pacing area shall also be provided.

The most applicable location for this technique is on high-volume/high-speed urban and rural freeways and other multi-lane access controlled facilities for work such as overhead utility work, installing overhead sign structures, replacing sign panels, and installing cantilever trusses. Utilizing traffic pacing for other types of work should be discussed with Traffic & Highway Safety Division and the Work Zone Coordinator before being allowed.

Preparation of a traffic pacing design shall be completed in order to plan and provide adequate work time to complete the short duration overhead construction. Based on the required work time and other inputs such as traffic volumes, regulatory speed and pacing speed, the traffic control plan defines the allowable pacing hours, pacing distance, location of warning signs, interchange ramp closures and other critical information. The Traffic Pacing Worksheet shall be used when planning to use this traffic control technique, in order to calculate the pacing distance and the time intervals during which a pacing operation may be allowed. Also refer to the Staging Plan Details and Traffic Pacing Changeable Message Signs Layout.