Category:403 Asphaltic Concrete Pavement: Difference between revisions

No edit summary |

|||

| (88 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

{|style="padding: 0.3em; margin-left:15px; border:1px solid #a9a9a9; text-align:center; font-size: 95%; background:#f5f5f5" width=" | {|style="padding: 0.3em; margin-left:7px; border:1px solid #a9a9a9; text-align:center; font-size: 95%; background:#ffddcc" width="180px" align="right" | ||

|- | |||

|'''Asphalt, Permeability''' | |||

|- | |||

|[https://spexternal.modot.mo.gov/sites/cm/CORDT/or10010.pdf Report 2009] | |||

|- | |||

|'''See also:''' [https://www.modot.org/research-publications Research Publications] | |||

|} | |||

{|style="padding: 0.3em; margin-left:15px; border:1px solid #a9a9a9; text-align:center; font-size: 95%; background:#f5f5f5" width="300px" align="right" | |||

|- | |- | ||

|'''Forms''' | |'''Forms''' | ||

| Line 6: | Line 15: | ||

|- | |- | ||

|[[Media:403 Form Profilograph Report.doc| Profiloqraph Report]] | |[[Media:403 Form Profilograph Report.doc| Profiloqraph Report]] | ||

|- | |||

|'''QRGs''' | |||

|- | |||

|[[:Category:101 Standard Forms#SuperPave Adjustments|SuperPave Adjustments]] | |||

|- | |||

|[[media:403 Performance Testing Asphalt QRG.pdf|Performance Testing Sample]] | |||

|- | |||

|'''AC Price Index Adjustments''' | |||

|- | |||

|[https://epg.modot.org/forms/CM/403_Guidance_for_Asphalt_Cement_Price_Index_Adjustments.docx Guidance for Asphalt Cement Price Index Adjustments] | |||

|- | |||

|'''Related Information''' | |||

|- | |||

|[https://modotgov.sharepoint.com/sites/cm/FormServerTemplates/104_7_Maintenance.docx Guidance for Administering and Planning Pavement Maintenance Responsibilities during Construction] | |||

|} | |} | ||

==403.1 Construction Inspection== | ==403.1 Construction Inspection for Sec 403== | ||

===403.1.1 Description (Sec 403.1)=== | ===403.1.1 Description (Sec 403.1)=== | ||

There will be no commentary for sections in which the intent of the | There will be no commentary for sections in which the intent of the | ||

| Line 16: | Line 38: | ||

'''Design Levels''' (Sec 403.1.2) | '''Design Levels''' (Sec 403.1.2) | ||

At the contractor’s expense, a mix with the same size aggregate and one design level higher can be substituted for the mix required by the contract | At the contractor’s expense, a mix with the same size aggregate and one design level higher can be substituted for the mix required by the contract at the price of the lower mix. Care should be taken to assure that the material product codes reflect the mix actually placed on the roadway. The substitutions must be done uniformly and various design levels in the same lift will not be allowed. | ||

===403.1.2 Material (Sec 403.2)=== | ===403.1.2 Material (Sec 403.2)=== | ||

See also [[1002 Aggregate for Asphaltic Concrete|Aggregate for Asphaltic Concrete]], [[1015 Bituminous Material|Bituminous Material]] and [[1071 Asphalt Release Agents, Fiber Additives and Liquid Anti- | See also [[:category:1002 Aggregate for Asphaltic Concrete|Aggregate for Asphaltic Concrete]], [[:category:1015 Bituminous Material|Bituminous Material]] and [[:Category:1071 Asphalt Release Agents, Fiber Additives and Liquid Anti-strip Additives|Asphalt Release Agents, Fiber Additives and Liquid Anti-Strip Additives]] for Materials information. | ||

'''Fine Aggregate Angularity (FAA)''' (Sec 403.2.1) | '''Fine Aggregate Angularity (FAA)''' (Sec 403.2.1) | ||

| Line 46: | Line 68: | ||

'''SP125xSM Requirements''' (Sec 403.2.5) | '''SP125xSM Requirements''' (Sec 403.2.5) | ||

In a Stone Matrix Asphalt (SMA) mix, the coarse aggregate will consist of crushed limestone and either porphyry or steel slag. SMA mixes have flat and elongated requirements for ratios of 5:1 and 3:1. The maximum allowable percentages of flat and elongated particles based on these ratios are given in Standard Specification Section 403.2.5. | In a Stone Matrix Asphalt (SMA) mix, the coarse aggregate will consist of crushed limestone and a hard durable aggregate, i.e. low Los Angeles Abrasion and absorption. Durable aggregate is generally either porphyry or steel slag but may be aggregates such as crushed gravel or quartzite. Mixtures designated as SMR, for rural interstates, may use 100% dolomite aggregates. SMA mixes have flat and elongated requirements for ratios of 5:1 and 3:1. The maximum allowable percentages of flat and elongated particles based on these ratios are given in Standard Specification Section 403.2.5. | ||

'''Filler Restriction''' (Sec 403.2.5.1) | '''Filler Restriction''' (Sec 403.2.5.1) | ||

| Line 55: | Line 77: | ||

Cellulose or mineral fibers, in accordance with Standard Specification Section 1071.4, must be used as a stabilizer in SMA mixes. Because the aggregate gradation of an SMA mix is gap-graded, fibers are used to increase the surface area of the mix and hold the binder in the mix. The fibers do not absorb the binder. The manufacturer, brand name, and dosage rate will be shown on the JMF. Fibers are proportioned by weight in both batch and drum plants. If an SMA mix is produced in a batch plant, the fibers can be added to the aggregate in the weigh hopper or in the pugmill. This can be done manually or mechanically with a metering device. If the fibers are added in the weigh hopper, aggregate from at least one hot bin must be discharged into the hopper before the fibers are added. If the fibers are added in the pugmill, the fibers must be added after the aggregate and before the binder. In either case, the dry mixing time shall be a minimum of 20 seconds and the wet mixing time shall be a minimum of 35 seconds. The mixing times and/or temperatures should be adjusted if a uniform mix is not produced. If an SMA mix is produced in a drum plant, the fibers can be added to the drum in loose or pelletized form. The fibers shall be uniformly and continuously metered into the mix. The metering system must be interlocked with the blending system. Pelletized fibers are added to the drum through the RAP inlet. Record all fiber shipments in the corresponding APIW. The inspector should verify that the manufacturer and brand name are included on the Pre-Acceptance List (PAL) and that the dosagerate meets the minimum requirements of Standard Specification Section 403.2.5.2. Fibers will be sampled in accordance with the PAL requirements and shipped to the Central Laboratory for testing. More information on the PAL requirements can be found in Standard Specification Section 106.12 and [[:Category:106 Control of Material|Control of Material]]. | Cellulose or mineral fibers, in accordance with Standard Specification Section 1071.4, must be used as a stabilizer in SMA mixes. Because the aggregate gradation of an SMA mix is gap-graded, fibers are used to increase the surface area of the mix and hold the binder in the mix. The fibers do not absorb the binder. The manufacturer, brand name, and dosage rate will be shown on the JMF. Fibers are proportioned by weight in both batch and drum plants. If an SMA mix is produced in a batch plant, the fibers can be added to the aggregate in the weigh hopper or in the pugmill. This can be done manually or mechanically with a metering device. If the fibers are added in the weigh hopper, aggregate from at least one hot bin must be discharged into the hopper before the fibers are added. If the fibers are added in the pugmill, the fibers must be added after the aggregate and before the binder. In either case, the dry mixing time shall be a minimum of 20 seconds and the wet mixing time shall be a minimum of 35 seconds. The mixing times and/or temperatures should be adjusted if a uniform mix is not produced. If an SMA mix is produced in a drum plant, the fibers can be added to the drum in loose or pelletized form. The fibers shall be uniformly and continuously metered into the mix. The metering system must be interlocked with the blending system. Pelletized fibers are added to the drum through the RAP inlet. Record all fiber shipments in the corresponding APIW. The inspector should verify that the manufacturer and brand name are included on the Pre-Acceptance List (PAL) and that the dosagerate meets the minimum requirements of Standard Specification Section 403.2.5.2. Fibers will be sampled in accordance with the PAL requirements and shipped to the Central Laboratory for testing. More information on the PAL requirements can be found in Standard Specification Section 106.12 and [[:Category:106 Control of Material|Control of Material]]. | ||

<div id="Reclaimed Asphalt"></div> | |||

'''Reclaimed Asphalt''' (Sec 403.2.6) | |||

Both reclaimed asphalt pavement (RAP) and reclaimed asphalt shingles (RAS) are allowed in some mix types by specification but not all mix types. When RAP or RAS are allowed, the contractor chooses when and how much recycled material to utilize within the specification limits. Depending on how much RAP or RAS the contractor chooses to use, there may be additional requirements placed on the virgin binder by the specifications. Effective virgin binder is used to account for binder absorbed by the aggregates and is not available for blending with the reclaimed binder. | |||

[[media:403.1.2 Contribution of Binder from Recycled Materials 2016.xls|Reclaimed binder contribution is calculated]] using a spreadsheet provided on MoDOT’s website. When a mix design approval is based off of a blend chart binder grade or extracted binder grade, substitution of a different virgin binder may require additional testing to prove the specification requirements are met. | |||

===403.1.3 Composition of Mixtures (Sec 403.3)=== | ===403.1.3 Composition of Mixtures (Sec 403.3)=== | ||

| Line 69: | Line 98: | ||

===403.1.4 Job Mix Formula=== | ===403.1.4 Job Mix Formula=== | ||

The mix design procedure will be in accordance with [[#403.2 Materials Inspection|Materials Inspection]]. | The mix design procedure will be in accordance with [[#403.2 Materials Inspection for Sec 403|Materials Inspection]]. | ||

'''Approval''' (Sec 403.4.3) | '''Approval''' (Sec 403.4.3) | ||

No mix shall be produced or placed by the contractor or accepted for use by an inspector without an approved JMF. This includes mix transfers. The Materials Field Office (MFO) will | No mix shall be produced or placed by the contractor or accepted for use by an inspector without an approved JMF. This includes mix transfers. The Materials Field Office (MFO) will give written approval. District Materials may approve mix transfers if the mix quantity per project is 250 tons or less provided the mix type and contract binder grade match what’s listed on the plan sheets or change order. In some extreme cases, approval may be verbal with written approval to follow. Occasionally, contractors may elect to place mix while the request is still pending. In this situation, contractors are proceeding at their own risk and should be so advised by an order record. | ||

give written approval. In some extreme cases, approval may be verbal with written approval to | |||

follow. Occasionally, | |||

this situation, | |||

'''Job Mix Formula Modifications''' (Sec 403.4.4) | '''Job Mix Formula Modifications''' (Sec 403.4.4) | ||

A new JMF will be required if a material source is changed or if unsatisfactory results are | A new JMF will be required if a material source is changed or if unsatisfactory results are obtained. The exception for the new JMF requirement will be when a binder source change has been made to a supplier, previously provided by the contractor in the original JMF, for which an alternate JMF number has already been created. Unsatisfactory results may include a mix that fails to meet specifications (binder content, volumetrics, and/or density) or if the visual appearance of the mix is unacceptable. If a new JMF is required, the procedures outlined in Standard Specification Section 403.11 should be followed. | ||

obtained. Unsatisfactory results may include a mix that fails to meet specifications (binder content, volumetrics, and/or density) or if the visual appearance of the mix is unacceptable. If a new JMF is required, the procedures outlined in Standard Specification Section 403.11 should be followed. | |||

===403.1.5 Mixture Production Specification Limits (Sec 403.5)=== | ===403.1.5 Mixture Production Specification Limits (Sec 403.5)=== | ||

Intentional deviations from the JMF will not be permitted. The plant shall be operated in such a manner that the mix is produced as shown on the JMF. The specification tolerances are developed in an attempt to keep the mix as consistent as possible and to allow for some variation during production. However, these tolerances are not production limits. For example, if the target binder content is 5.0%, the binder content of the mix can range from 4.7% to 5.3% when the tolerances are applied. The contractor will not be allowed to produce the mix at 4.7% to save money. | Intentional deviations from the JMF will not be permitted, except under the conditions set forth in Sec 403.11. The plant shall be operated in such a manner that the mix is produced as shown on the JMF. The specification tolerances are developed in an attempt to keep the mix as consistent as possible and to allow for some variation during production. However, these tolerances are not production limits. For example, if the target binder content is 5.0%, the binder content of the mix can range from 4.7% to 5.3% when the tolerances are applied. The contractor will not be allowed to produce the mix at 4.7% to save money. | ||

Operating out of the specifications may reduce the contractor's pay and/or the pavement service life. When QC tests, either random or informational, are out of specification tolerances, the contractor should adjust the production to bring the mix back in. When QA tests are out of specification tolerances, the contractor should be notified immediately. The contractor is responsible for deciding when adjustments are made to control the mix. Some test properties may be allowed to deviate beyond specification limits occasionally, provided that adjustments are made and the following tests show that production is back within limits. | |||

Production may be required to cease if the random QC or QA test results are either out of specifications far enough to indicate that the mix may be subject to failure or beyond the specification removal limits. Production should cease until verification that the problem has been corrected. An order record should be written, on the same day or the next day if paving occurs at night, describing the deficiency and the location and amount of mix affected. The contractor may elect to continue production in order to run more tests. If so, the order record should state that any mix produced after the order record was issued is at the contractor’s risk. Final disposition of the mix can then be made based on all tests and observations and may consist of acceptance at a reduced price or removal and replacement of unacceptable material. | |||

Both QC and QA will use the following procedures to determine volumetrics of the mix and compliance with Standard Specification Sections 403.5.3 through 403.5.5. These procedures are discussed in greater detail in the Levels 1 and 2 Bituminous Training. | |||

In situations where a retained sample must be tested, the following procedure should be used to reheat the sample. Heat the sample in an oven until the mix is workable. Take the mix out of the sample container (box, bucket, etc.) and spread it in a large pan or several smaller pans. Using this procedure, the mix will reach the molding temperature much quicker than it would if it were left in a mass in the sample container. Also, less aging of the mix occurs since the mix is in the oven for a shorter period of time. Once the mix has reached an acceptable temperature, quarter split the mix. The split portions to be used for making gyratory specimens shall then be heated to the compaction temperature. The entire suite of tests must be performed on a retained sample. | |||

In situations where a retained sample must be tested, the following procedure should be used to reheat the sample. Heat the sample in an oven until the mix is workable. Take the mix out of the sample container (box, bucket, etc.) and spread it in a large pan or several smaller pans. Using this procedure, the mix will reach the molding temperature much quicker than it would if it were left in a mass in the sample container. Also, less aging of the mix occurs since the mix is in the oven for a shorter period of time. Once the mix has reached an acceptable temperature, the | |||

'''Gradation''' (Sec 403.5.1) | '''Gradation''' (Sec 403.5.1) | ||

| Line 167: | Line 179: | ||

mix, as determined by sampling and testing, shall be within ±0.3% of the target listed on the JMF. | mix, as determined by sampling and testing, shall be within ±0.3% of the target listed on the JMF. | ||

<div id="Voids in the Mineral Aggregate (VMA) (Sec 403.5.4)"> | <div id="Voids in the Mineral Aggregate (VMA) (Sec 403.5.4)"></div> | ||

'''Voids in the Mineral Aggregate (VMA)''' (Sec 403.5.4) | '''Voids in the Mineral Aggregate (VMA)''' (Sec 403.5.4) | ||

| Line 181: | Line 193: | ||

!style="background:#BEBEBE"|Mix Type||style="background:#BEBEBE"|VMA Limits (percent) | !style="background:#BEBEBE"|Mix Type||style="background:#BEBEBE"|VMA Limits (percent) | ||

|- | |- | ||

| SP250 || 11.5-14.0 | |align="center"| SP250 ||align="center"| 11.5-14.0 | ||

|- | |- | ||

|SP190|| 12.5-15.0 | |align="center"|SP190||align="center"| 12.5-15.0 | ||

|- | |- | ||

|SP125|| 13.5-16.0 | |align="center"|SP125||align="center"| 13.5-16.0 | ||

|- | |- | ||

| | |align="center"|SP095||align="center"|14.5-17.0 | ||

|- | |||

|align="center"|SP048||align="center"| 15.5-18.0 | |||

|- | |||

|align="center"|SMA||align="center"| 16.5-19.0 | |||

|} | |} | ||

| Line 196: | Line 212: | ||

minimums and should be increased as necessary. The V<sub>a</sub> for all mixes shall be 4.0 ±1.0%. | minimums and should be increased as necessary. The V<sub>a</sub> for all mixes shall be 4.0 ±1.0%. | ||

<div id="Tensile Strength Ratio (TSR) (Sec 403.5.6)"> | <div id="Tensile Strength Ratio (TSR) (Sec 403.5.6)"></div> | ||

'''Tensile Strength Ratio (TSR)''' (Sec 403.5.6) | '''Tensile Strength Ratio (TSR)''' (Sec 403.5.6) | ||

| Line 202: | Line 218: | ||

stripping. | stripping. | ||

During production, loose mix samples will be taken and quartered as described in [[#403.1.5 Mixture Production Specification Limits (Sec 403.5)|Mixture Production Specification Limits]]. TSR samples | During production, loose mix samples will be taken and quartered as described in [[#403.1.5 Mixture Production Specification Limits (Sec 403.5)|Mixture Production Specification Limits]]. TSR samples need to be taken from random locations. However, they should be taken whenever it is convenient to production, such as during a big gap between QC volumetric tests. By specification, sampling locations are from the roadway behind the paver, however, should the MoDOT inspector deem this an unsafe or impractical location, the sample may be taken from the plant. The QA sample(s) should be taken from the same point as the QC sample(s). If QC takes their sample from the plant, QA should take their sample from the plant also. This does not mean that QA should be taking their samples at the same time as QC. Two opposite quarters will be retained and the remaining two quarters will be mixed together and tested in accordance with AASHTO T283. | ||

QC should obtain enough mix to retain a sample. QC will sample and test each mix at a minimum of once every 10,000 tons, or fraction thereof. QA will independently sample and test each mix at a minimum of once every 50,000 tons. The TSR sampling requirements are best described with an example. Suppose that 112,960 tons of SP190 are to be placed on a project. By specification, QC is required to take twelve samples and QA is required to take three samples. There are two possible scenarios for sampling this mix. QC may take eleven samples representing 10,000 tons each and a twelfth sample that represents the remaining 2,960 tons. Or QC may take ten samples that represent 10,000 tons each and two samples that represent the remaining 12,960 tons (6,480 tons each). Either scenario is acceptable. Likewise, QA may take two samples representing 50,000 tons each and a third sample that represents the remaining 12,960 tons. Or QA may take one sample that represents 50,000 tons | QC should obtain enough mix to retain a sample. QC will sample and test each mix at a minimum of once every 10,000 tons, or fraction thereof. QA will independently sample and test each mix at a minimum of once every 50,000 tons. The TSR sampling requirements are best described with an example. Suppose that 112,960 tons of SP190 are to be placed on a project. By specification, QC is required to take twelve samples and QA is required to take three samples. There are two possible scenarios for sampling this mix. QC may take eleven samples representing 10,000 tons each and a twelfth sample that represents the remaining 2,960 tons. Or QC may take ten samples that represent 10,000 tons each and two samples that represent the remaining 12,960 tons (6,480 tons each). Either scenario is acceptable. Likewise, QA may take two samples representing 50,000 tons each and a third sample that represents the remaining 12,960 tons. Or QA may take one sample that represents 50,000 tons and two samples that represent the remaining 62,960 tons (31,480 tons each). The contract quantity may be used to approximate sample 1 locations. | ||

QA | MoDOT should collect at least 250 pounds of asphalt mix for the QA sample, 125 pounds is retained by the RE and the other 125 pounds is sent to the Central Laboratory (typically) in 4 – 13” x 13” x 4.5” boxes for QA testing. Each box must be labeled on one side with the AASHTOWARE Project (AWP) ID, Mix Type, VMA Limits (percent) number and the mix number. An AWP record must be created for each sample, which must include all required information, the mix number, sample date, and the represented tonnage. The represented tonnage is explained in the example in the preceding paragraph. It is recommended to include the lot and sublot to the AWP record as additional information. | ||

boxes | |||

Mix Type VMA Limits (percent) number and the mix number. | |||

Additional information that may be included in the | Additional information that may be included in the AWP record is the G<sub>mm</sub> from the sublot that the sample was taken in (QC or QA) and the specimen weight that QC has been using. The specimen weight may be different from that shown on the JMF because of bin percent changes, etc. This information is helpful because it results in less trial-and-error for the Central Laboratory. | ||

In the laboratory, a minimum of six specimens are compacted to a height of approximately 95 mm. The air voids of the specimens are calculated. For all mixes other than SMA, the air voids must be within 7.0 ±0.5%. For SMA mixes, the air voids must be within 6.0 ±0.5%. Half of these specimens are saturated, frozen, and thawed. These are the conditioned specimens. The degree of saturation of the conditioned specimens is also calculated. The remaining specimens are unconditioned. Then, the indirect-tensile strength of all of the specimens is determined. | In the laboratory, a minimum of six specimens are compacted to a height of approximately 95 mm. The air voids of the specimens are calculated. For all mixes other than SMA, the air voids must be within 7.0 ±0.5%. For SMA mixes, the air voids must be within 6.0 ±0.5%. Half of these specimens are saturated, frozen, and thawed. These are the conditioned specimens. The degree of saturation of the conditioned specimens is also calculated. The remaining specimens are unconditioned. Then, the indirect-tensile strength of all of the specimens is determined. Therefore, the TSR is the ratio of the average tensile strength of the conditioned specimens to the average tensile strength of the unconditioned specimens. | ||

Therefore, the TSR is the ratio of the average tensile strength of the conditioned specimens to the average tensile strength of the unconditioned specimens. | <div id="A favorable comparison will be obtained"></div> | ||

A favorable comparison will be obtained if the QC and QA test results are within 10% of each other. The contractor’s pay will be adjusted in accordance with Standard Specification Section | A favorable comparison will be obtained if the QC and QA test results are within 10% of each other. The contractor’s pay will be adjusted in accordance with Standard Specification Section 403.23.5 based on the QC test results. For example, if the QC TSR is 95% and the QA TSR is 93%, a favorable comparison has been obtained and the contractor will receive a 3% bonus. However, if the difference is greater than 10%, the field office should be consulted. The field office will evaluate the air voids and saturation levels. The raw data should be collected from QC and forwarded to the field office for comparison in order to determine whether it will be necessary to proceed with 3<sup>rd</sup> party testing. QC and QA retained samples should be kept for an extended period of time so that they may be used during dispute resolution, if necessary. | ||

403.23.5 based on the QC test results. For example, if the QC TSR is 95% and the QA TSR is 93%, a favorable comparison has been obtained and the contractor will receive a | |||

The QC data should be reported in AWP (Test - SAA402AB). Contractors may report their own test results using the TSR Contractor Reporting Excel to Oracle Spreadsheet available on the MoDOT [http://www.modot.org/business/contractor_resources/Quality_Management/ Quality Management] website. Furthermore, this information is quarried regularly and, provided that a favorable comparison is reached, used to signal the appropriate time for disposal of the remaining TSR sample at the Central Lab. | |||

<div id="Aggregate Properties"></div> | |||

'''Aggregate Properties''' (Sec 403.5.7) | '''Aggregate Properties''' (Sec 403.5.7) | ||

The aggregate consensus tests (Fine and Coarse Aggregate Angularity, Clay Content, and Thin, Elongated Particles) are performed on the blended aggregate. | The aggregate consensus tests (Fine and Coarse Aggregate Angularity, Clay Content, and Thin, Elongated Particles) are performed on the blended aggregate. The aggregate will be sampled from the combined cold feed whether dealing with a drum-mix plant or a batch plant. | ||

For each mix that is produced, QC shall sample the aggregate and perform the consensus tests once every 10,000 tons with a minimum of one per mix per project. QA will independently sample the aggregate and perform the consensus tests once per project. QA should also test a minimum of one QC retained sample per project. For large projects, enough QC retained samples should be tested to ensure that QC is performing the tests correctly. These testing requirements are minimums and should be increased as necessary. During production, the following tolerances are applied (see Standard Specification Sections 403.2.1 through 403.2.5 and [[media:403 Figure Consensus Testing.pdf|Consensus Testing]]). | For each mix that is produced, QC shall sample the aggregate and perform the consensus tests once every 10,000 tons with a minimum of one per mix per project. QA will independently sample the aggregate and perform the consensus tests once per project. QA should also test a minimum of one QC retained sample per project. For large projects, enough QC retained samples should be tested to ensure that QC is performing the tests correctly. These testing requirements are minimums and should be increased as necessary. During production, the following tolerances are applied (see Standard Specification Sections 403.2.1 through 403.2.5 and [[media:403 Figure Consensus Testing.pdf|Consensus Testing]]). | ||

| Line 235: | Line 251: | ||

| Clay Content|| 5% below the minimum | | Clay Content|| 5% below the minimum | ||

|- | |- | ||

|Thin, Elongated Particles|| 2% | |Thin, Elongated Particles|| 2% above the maximum | ||

|} | |} | ||

| Line 270: | Line 286: | ||

'''Substitutions''' (Sec 403.10.2) | '''Substitutions''' (Sec 403.10.2) | ||

The intent of this specification is that there be no additional cost to MoDOT as a result of the allowed substitution. Payment should be made for the mixture originally set up in the contract. Material codes for the substitute mixture should be entered in | The intent of this specification is that there be no additional cost to MoDOT as a result of the allowed substitution. Payment should be made for the mixture originally set up in the contract. Material codes for the substitute mixture should be entered in AWP on the line for which payment is being made. For example: Assume that the contractor wishes to use SP125 in lieu of the SP190 that is set up in the plans and that the SP125 has a higher contract unit price. Payment for the substitute mix should be paid as SP190. Material codes for SP125 should be added to the line for SP190 so that material quantities can be tracked and documented. | ||

===403.1.11 Field Adjustments of Job Mix Formulas (Sec 403.11)=== | ===403.1.11 Field Adjustments of Job Mix Formulas (Sec 403.11)=== | ||

When test results indicate that the mixture does not meet the specification requirements, the contractor may adjust the JMF in the field. The total binder content may be adjusted by a maximum of 0.3% from the original JMF. Virgin aggregate fractions may be adjusted as necessary except that they may not be eliminated entirely unless they are 5% or less of the original JMF. Consult the Field Office before eliminating virgin aggregate fractions greater than 5%. The addition of any new fraction will require a new mix design. The RAS fraction may be adjusted by a maximum of 3% from the original JMF. The RAP fraction may be adjusted by a maximum of 15% from the original JMF. | |||

the original JMF | Any time that adjustments are made to the plant percentages, including the hot bin percentages, the inspector and RE must be notified immediately. The resulting combined aggregate gradation of the adjusted mix must be within the master range for that particular type of mix (see Standard Specification Section 403.3.1). During production of the adjusted mix, the combined aggregate gradation must be within the limits of Standard Specification Section 403.5.1.1 or 403.5.1.2, whichever is applicable. If the cold feed settings have been adjusted, the composition of the mix has been changed. Therefore, the new bulk specific gravity of the combined aggregate (G<sub>sb</sub>) must be calculated using the adjusted cold feed percentages so that the VMA can be accurately calculated during production. If an adjustment from the job mix is made, the contractor should be required to recalculate the porphyry/Non-carbonate percentage to assure that is still meets the contract requirements. The [[media:403.1.11 Durable Aggregate Calculation.xlsx|Durable Aggregate Calculation spreadsheet]] has been developed to assist in checking the contractor’s calculation. If the percentage of RAS or RAP is increased from the original JMF the percent virgin effective binder replacement (P<sub>bv</sub>) should be recalculated to assure compliance with section 403.2.5 of the Standard Specifications. The P<sub>bv</sub> should also be recalculated when the percent of binder in the RAP changes as determined by Section 403.19.3. | ||

from the original JMF. Any time that adjustments are made to the plant percentages, including the hot bin percentages, the inspector and RE must be notified immediately. The resulting combined aggregate gradation of the adjusted mix must be within the master range for that particular type of mix (see Standard Specification Section 403.3.1). During production of the adjusted mix, the combined aggregate gradation must be within the limits of Standard Specification Section 403.5.1.1 or 403.5.1.2, whichever is applicable. If the cold feed settings have been adjusted, the composition of the mix has been changed. Therefore, the new bulk specific gravity of the combined aggregate (G<sub>sb</sub>) must be calculated using the adjusted cold feed percentages so that the VMA can be accurately calculated during production. If an adjustment from the job mix is made, the contractor should be required to recalculate the porphyry/Non-carbonate percentage to assure that is still meets the contract requirements. | |||

spreadsheet has been developed to assist in checking the contractor’s calculation. | |||

'''Field Mix Redesign''' (Sec 403.11.1) | '''Field Mix Redesign''' (Sec 403.11.1) | ||

| Line 355: | Line 369: | ||

'''Joint Composition''' (Sec 403.16.1) | '''Joint Composition''' (Sec 403.16.1) | ||

Unconfined joint density should be measured on the first pass in the 6 inches adjacent to the vertical edge (if the contractor is taking 6-inch density cores the location should be adjusted as necessary to avoid the vertical face). After the second paver pass closes the unconfined joint, the entire width of the lane may be used for random density testing, including the entire wedge portion of a notched wedge section. | |||

mixes, except for SMA, shall have a minimum unconfined joint density of 90.0%. SMA mixes shall have a minimum unconfined joint density of 92.0%. Confined joint densities will be evaluated with the remainder of the mat and must meet the density requirements of Standard Specification | |||

All mixes, except for SMA, shall have a minimum unconfined joint density of 90.0%. SMA mixes shall have a minimum unconfined joint density of 92.0%. Confined joint densities will be evaluated with the remainder of the mat and must meet the density requirements of Standard Specification | |||

Section 403.5.2. | Section 403.5.2. | ||

===403.1.17 Quality Control (Sec 403.17)=== | ===403.1.17 Quality Control (Sec 403.17)=== | ||

Under QC/QA, the contractor performs quality control (QC) testing. The contractor is paid based on the results of the randomly located QC tests for Superpave mixes. Beyond random QC tests, quality control by the contractor consists of constantly monitoring materials integrity, mix production and laydown operations to ensure overall acceptability. | |||

<div id="Asphalt Test Results (Sec 403.17.1.1)"> | <div id="Asphalt Test Results (Sec 403.17.1.1)"> | ||

'''Asphalt Test Results''' (Sec 403.17.1.1) | '''Asphalt Test Results''' (Sec 403.17.1.1) | ||

A copy of all QC test results shall be furnished to the QA inspector no later than the beginning of the day after testing has been performed. All raw data and printouts must be included with the testing records. Raw data consists of all weights, measurements,etc. used to arrive at the final test results. Printouts include the gyration/height data from the gyratory compactor and the asphalt content ticket from the binder ignition oven or nuclear gauge. The testing records must be available to the QA inspector at all times. | A copy of all random QC test results shall be furnished to the QA inspector no later than the beginning of the day after testing has been performed. All raw data and printouts must be included with the testing records. Raw data consists of all weights, measurements, etc. used to arrive at the final test results. Printouts include the gyration/height data from the gyratory compactor and the asphalt content ticket from the binder ignition oven or nuclear gauge. The QC testing records must be made available to the QA inspector at all times. | ||

It is QC’s responsibility to take appropriate action if unsatisfactory mix is being produced. This may include making adjustments to the plant to bring the mix back into specification, sampling the mix from the roadway and performing informational testing, removing mix from the roadway, etc. | |||

'''Informational Tests''' | |||

An informational test is a test that QC may perform between random testing to determine whether or not the mix is within specifications. Informational testing is not required and may be performed at any time and at any frequency. Generally, informational testing will be performed early in the production period. The informational test may not be completed in full. For example, QC may only compact the gyratory specimens. Doing so will yield specimen heights and the contractor may or may not make production adjustments based on these heights. Informational test samples must be clearly marked as such if they are tested and stored in the field laboratory. | |||

QC is not required to provide the QA inspector with informational test results, since informational tests cannot be used in the QC process to determine pay factors, The timing of random number locations being given to the contractor, typically 100 to 150 tons in advance, is meant to protect the integrity of the statistical sampling process. QA always has the option of taking its own informational samples. | |||

Informational test data may be used to determine asphalt removal limits if it is adequately documented. It should not be used for QLA under any circumstances. To be considered adequately documented the following criteria should be met: | |||

*The gyratory pucks should be clearly identified and labeled and made available for verification. | *The gyratory pucks should be clearly identified and labeled and made available for verification. | ||

| Line 374: | Line 397: | ||

*The printout from the AC test should be available. | *The printout from the AC test should be available. | ||

If the preceding conditions are met and the gyratory specimens are used to troubleshoot the placement, the specimens can then be weighed and bulked to determine the volumetric properties. Data from | If the preceding conditions are met and the gyratory specimens are used to troubleshoot the placement, the specimens can then be weighed and bulked to determine the volumetric properties. Data from informational tests is approximate. Its only legitimate use to the QA inspector is to help determine the point on the roadway where the mixture transitioned either above or below the removal limits. We don’t want to remove acceptable mix or leave unacceptable mix in place. | ||

'''Removal Limits''' | |||

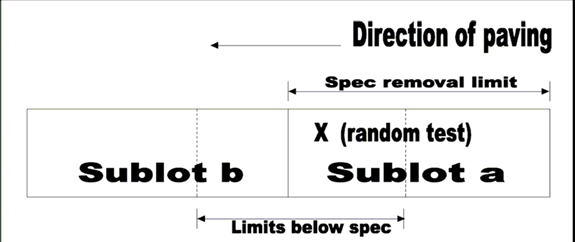

As an example of how informational tests may be used to designate removal limits of failing QC samples, the following situation is provided. The random QC sample shown in the diagram below fell late in sublot ‘a’ and test results indicated that voids were below the limits for removal. By specification sublot ‘a’ should be removed. By the time the test results were available and corrective action was taken, the contractor had crossed into sublot ‘b’. Assuming that mix properties were acceptable at the beginning of sublot ‘a’, the actual limits of unacceptable material are indicated by the dashed lines. | |||

Adhering strictly to the specification, it is likely that acceptable material early in sublot ‘a’ will be removed, and it is also likely that unacceptable material early in sublot ‘b’ will be left in place. An adequately documented informational test may be used to zero in on the transitions out of, and back into, acceptable mix. It doesn’t matter that the data is approximate, only that it is above the limit for removal. | |||

Random tests within removal limits are to be replaced by an equal number of random QC test locations, regardless of tonnage. For example, if 750 tons replace an area covered by two random tests, the new tests would be randomly chosen in each 375 ton portion of the replaced mixture. | |||

The resident engineer has the option to determine removal limits based on puck height, provided that the informational test data is consistent with previous production. | |||

[[image:403_removal_limits.png|950px|center|thumb|<center>]] | |||

When the random QC density core is below or above the removal limits, additional cores may be cut using the following procedure to determine the area of removal. Locations 250’ parallel to the centerline, ahead and back of the failing QC location, will be determined by the engineer. Cores will be cut in these locations and tested. If both sets of cores are not below or above the removal limits, the 500’ section will be removed and replaced with acceptable material and a new random QC core will be cut with-in the new pavement. If either set of the cores are below or above the removal limits, the whole sublot or the area in which the density core represents is subject to removal. | |||

Any sublot of material with air voids in the compacted specimens less than 2.5 percent shall be evaluated with Hamburg testing and removed and replaced with acceptable material by the contractor if the rut depth is greater than 14.0 mm. | |||

<div id="level of service (LOS)"></div> | |||

'''Inertial Profiler Test Results''' (Sec 610) | |||

Surface of the pavement should be thoroughly tested with an inertial profiler or straightedge as required by [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=9 Sec 610]. The procedures for testing with an inertial profiler and analyzing the results with the ProVAL software program are set forth in [[106.3.2.59 TM-59, Determination of the International Roughness Index|EPG 106.3.2.59 TM-59, Determination of the International Roughness Index]]. | |||

'''Bituminous Quality Control Plan''' (Sec 403.17.2) | '''Bituminous Quality Control Plan''' (Sec 403.17.2) | ||

The contractor documents the QC method with a quality control plan (QC Plan*). The QC plan for Superpave mixes shall include the contact information of the contractor’s QC representative, lot and sublot sizes and how they will be designated, the test method for determining asphalt binder content, the number of cores to be cut for density determination, and the independent third party for dispute resolution. The QC plan is approved by MoDOT Construction and Materials and used as a contract document during mix production. Contractor technicians who perform materials testing shall be certified through the MoDOT Technician Certification Program (TCP). | |||

*Note*: A QC Plan is not required for bituminous base (BB) and pavement (BP) mixes. | |||

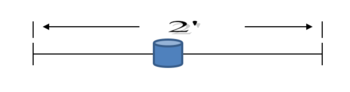

Up to 3 cores are allowed at each random location, but only if spelled out in the QC plan. In the drawing below, the cylinder represents the station and offset of the random location. Best management practice is for QA to mark that location on the pavement. The first density core should have that marking on it. Any additional cores should be taken along a straight line, parallel to the centerline, within 1 foot either side of the random location. | |||

[[image:403_2foot.png|350px|center|thumb|<center>]] | |||

'''Plant Calibration''' (Sec 403.17.2.2) | '''Plant Calibration''' (Sec 403.17.2.2) | ||

| Line 395: | Line 436: | ||

'''Retained Samples''' (Sec 403.17.2.3) | '''Retained Samples''' (Sec 403.17.2.3) | ||

QC must retain the portion of each sample that is not tested after the sample has been reduced to testing size. This includes gradation, consensus, TSR, and volumetrics samples. The retained samples must be clearly identified in accordance with Standard Specification Section 403.17.2.3 and stored in the field laboratory for a minimum of 7 days. Also, all cores must be retained for a minimum of 7 days. | QC must retain the portion of each sample that is not tested after the sample has been reduced to testing size. This includes gradation, consensus, TSR, and volumetrics samples. The retained samples must be clearly identified in accordance with Standard Specification Section 403.17.2.3 and stored in the field laboratory for a minimum of 7 days. Also, all cores must be retained for a minimum of 7 days. Notwithstanding the 7 day minimum, retained samples should not be discarded until all comparison issues with the lot are resolved. If space at the field lab is an issue, the sample should be stored at the project office. | ||

There is no legitimate reason for unidentified samples to be in the field laboratory. The QA inspector should insist that all test specimens in the field laboratory be marked as soon as they are cool enough. The identifying mark should be permanent, unique, and indicate what the sample is. | |||

When running a QC split sample, the comparisons should be within the tolerances shown in the following table: | |||

{| border="1" class="wikitable" style="margin: 1em auto 1em auto" | |||

|- | |||

!style="background:#BEBEBE"|Loose Mix Property||style="background:#BEBEBE"|Tolerance | |||

|- | |||

|align="center"| G<sub>mb</sub> ||align="center"| 0.010 | |||

|- | |||

|align="center"|G<sub>mm</sub>||align="center"| 0.010 | |||

|- | |||

|align="center"|AC %||align="center"| 0.1% | |||

|} | |||

'''Gradation Sample''' (Sec 403.17.2.3.1) | '''Gradation Sample''' (Sec 403.17.2.3.1) | ||

| Line 403: | Line 459: | ||

'''Loose Mix Sample''' (Sec 403.17.2.3.2) | '''Loose Mix Sample''' (Sec 403.17.2.3.2) | ||

A | A loose mix sample consisting of roughly 100 lbs. will be taken from the roadway behind the paver, in accordance with AASHTO T168, at the required frequency. The sample will be thoroughly mixed and quartered in accordance with AASHTO R47, or with an approved splitting/quartering device. Two opposite quarters will be retained for testing during the dispute resolution process, if necessary. The remaining two quarters will be mixed together and quartered again. | ||

The required weight of mix, as listed on the JMF, will be taken from one quarter and used to compact a specimen in accordance with AASHTO T312. The mix will be compacted to Ndes gyrations while the mix temperature is within the molding range listed on the JMF. Using the opposite quarter, follow the same procedure for the second specimen. The Gmb of each specimen will be determined and the average will be used to calculate the air voids Va and the voids in the mineral aggregate (VMA). By specification, a minimum of two compacted specimens must be used to calculate these properties. | |||

A third quarter will be used to determine the Gmm of the mix in accordance with AASHTO T209. The minimum sample size for each type of mix can be found in the training manual. This property is used to calculate the Va and density. The volume of the sample, which is needed in the calculation, can be determined by either the weigh-in-air method or the weigh-in-water method. The weigh-in-air method consists of weighing the sample and container (with the lid) completely filled with water in air. The weigh-in-water method consists of weighing the sample and container (without the lid) completely submerged in water. | |||

The remaining mix should be mixed together and quartered again. To determine the binder content using the nuclear gauge, enough mix should be taken from opposite quarters. The required weight of mix is listed on the JMF. A moisture content sample should be taken from the same quarters. To determine the binder content using the binder ignition oven, enough mix should be taken from one quarter. The minimum sample size for each type of mix can be found in the training manual. A moisture content sample should be taken from the same quarter. Sometimes the ignition oven may not shut itself off. The oven may be shut off manually as long as 3 consecutive readings show less than 0.01% loss. The sample should be examined to assure that a complete burn has been achieved. This will be considered a valid test. | |||

'''Quality Control Laboratory''' (Sec 403.17.3) | '''Quality Control Laboratory''' (Sec 403.17.3) | ||

The contractor is required to provide an appropriately equipped QC laboratory, however, it is not required to be at the plant. The contractor is also required to provide office space at the asphalt plant for the QA inspector to work on records and reports. Usually, these two requirements are met with one structure, but not always. The intent of the specification will be met if the QA inspector is provided with suitable facilities at the plant, but the lab is located offsite at another location, such as between the jobsite and the plant. The laboratory should have internet access in the event that cell phone service is not available. | |||

'''Calibration Schedule''' (Sec 403.17.3.1) | '''Calibration Schedule''' (Sec 403.17.3.1) | ||

| Line 417: | Line 481: | ||

===403.1.18 Quality Assurance (Sec 403.18)=== | ===403.1.18 Quality Assurance (Sec 403.18)=== | ||

'''Assurance Testing''' (Sec 403.18.1) | |||

''' | Under QC/QA, MoDOT performs quality assurance (QA) testing. QA testing is used to verify the QC results. MoDOT is also responsible for independent assurance sampling (IAS) to verify that both QC and QA are performing the testing correctly. | ||

All QA samples will be at independent random locations from QC. Not testing at random locations introduces statistical bias that is not in the interest of either MoDOT or the contractor. As with informational QC tests for the contractor, the MoDOT inspector may select specific locations for informational QA loose mix or core samples at any time if there is concern about a problem area, however, these may not be used for PWL calculations. | |||

For volumetric testing, QA must sample enough loose mix material to retain an adequate amount for a second test. This retained sample, as with the QC retained sample, may be used during dispute resolution. QA will randomly sample the mix from the roadway once per lot and perform volumetric testing. At the beginning of the project, QC and QA should be given the opportunity to witness each other’s sampling and testing procedures. Any discrepancies should be immediately resolved at the project level, if possible. QA should test a QC retained volumetric sample once per day to ensure that both QC and QA are testing correctly. These samples should also be chosen at random (do not consistently test the retained sample from the same sublot every lot or develop a pattern). | |||

For density testing, QA cores shall also be randomly located within a sublot at a frequency of one per lot. However, in the interest of public safety a random QA core test location, such as one in the middle of a busy intersection, should be moved to the closest safe location at the same random transverse offset. When both QC and QA are confident in each other’s testing procedures and favorable comparisons have been obtained on the retained samples, testing of the QC retained volumetric samples may be performed at a reduced frequency as determined by the MoDOT inspector. QA should test a QC retained gradation sample at a minimum of once per week. A minimum of one QC retained consensus sample should be tested per project. QA test results will be furnished to the contractor no later than the day after testing has been performed. A [[media:403 Form QAQC Project Checklist.doc|QA/QC Checklist]] is attached. | |||

{| border="1" class="wikitable" style="margin: 1em auto 1em auto" | |||

|+'''QA Test Type & Frequency''' | |||

! style="background:#BEBEBE" |QA Test Type!! style="background:#BEBEBE" |Minimum By Spec!! style="background:#BEBEBE" |Early in Project!! style="background:#BEBEBE" |Later in Project | |||

|- | |||

|Random QA for PWL||1/4 sublots|| 1/4 sublots|| 1/4 sublots | |||

|- | |||

|QC Split ||1/week || 1/day || At a reduced frequency as determined by the MoDOT inspector | |||

|} | |||

For single lift overlays and small quantity, QA cores shall be cut in the same location as the QC core. | |||

'''QA Core Chain of Custody''' (Sec 403.18.2) | |||

The roadway inspector should ensure that the QA density cores taken from the roadway are the same ones tested in the lab. The preferred procedure is for a MoDOT inspector to take possession of the cores as soon as they are cut and deliver them directly to QA at the plant, so that testing can proceed without delay. When job circumstances make this procedure impractical and the contractor has to deliver the core, the roadway inspector should dry the core with a paper towel and mark the side with identifying marks, including lot and sublot, using a permanent felt-tipped marker. Regardless of who delivers the QA core to the lab, the core shall be placed in a tamper proof bag. | |||

'''Aggregate Comparison''' (Sec 403.18. | '''Aggregate Comparison''' (Sec 403.18.3) | ||

A favorable comparison will be obtained when the independent QA sample(s) meets specifications. | A favorable comparison will be obtained when the independent QA sample(s) meets specifications. | ||

| Line 471: | Line 550: | ||

'''Random Numbers''' (Sec 403.19.1) | '''Random Numbers''' (Sec 403.19.1) | ||

All random numbers will be | All random numbers for QC loose mix samples and cores shall be generated prior to the start of the project for every four sublots. A printout of those numbers will be sealed in an envelope, which will be signed and dated by both QA and QC parties. The QA inspector will keep the envelopes in his/her possession in a secure location. The envelope for every four sublots will be provided to QC at the end of the previous four sublots. | ||

numbers | |||

QC samples that are used to determine the pay factors must be taken at the locations designated | It is critical that QC (and QA) samples be taken at random locations, because any manipulation of the locations introduces bias. QC test results are used to statistically define a population of data and bias causes inaccuracy in that statistical calculation. | ||

by the random numbers unless circumstances warrant relocation. This could include close | Random numbers shall be generated by using the Asphalt Random Locations spreadsheet, in order to eliminate any question of bias. MoDOT inspectors can locate the [http://eprojects/Templates/Asphalt_Random_Locations.xlsm Asphalt Random Locations ]sheet on the internal site. | ||

proximity to another QC sample location in the same production period, areas where mix must be | |||

placed by hand, etc. | QC samples that are used to determine the pay factors must be taken at the locations designated by the random numbers, unless circumstances warrant relocation. This could include close proximity to another QC sample location in the same production period (when QC is at a critical point in testing the previous sample), areas where mix must be placed by hand, etc. In these cases, using good judgment, QA has the authority to separate random samples by up to 200 tons. QC and QA need to work together in good faith to make this process run smoothly. | ||

be notified of the core location after rolling has been completed. QC should be notified of the | |||

loose mix sample location approximately 100 to 150 tons before the test. The independent QA sample must be taken at the location designated by | <u>QC should be notified of the core location after rolling has been completed. QC should be notified of the loose mix sample location approximately 100 to 150 tons before the test.</u> The intent is to give QC enough time to conclude any ongoing tests and collect the next samples. When the sampling for every four sublots is completed, the envelope for those sublots will be opened to demonstrate that the random numbers were not manipulated during production. | ||

The independent QA sample must be taken at the location designated by a random number unless circumstances warrant relocation. This could include close proximity to a QC sample location in the same production period, areas where mix must be placed by hand, etc. If necessary, the random samples may be separated by 200 tons. The QA inspector shall place and seal the QA core in a tamper-proof bag immediately after extraction and mark the bag label with the project number, lot number, location and inspector signature. The test results from the independent QA sample will be compared to the QC test results to determine if the QC test results adequately define the characteristics of the entire lot. However, QA may take additional samples to determine if an area of concern complies with the specifications. The test results of these additional samples will not be compared to any QC test results. | |||

'''Lots''' (Sec 403.19.2) | '''Lots''' (Sec 403.19.2) | ||

For the purposes of pay factor determination, the mat will be divided into lots with a minimum | For the purposes of pay factor determination, the mat will be divided into lots with a minimum of 4 sublots per lot. The maximum sublot size is 1000 tons. If a full lot cannot be completed, the extra sublots will be added to the previous full lot and the pay factors will be determined on the large lot. If there is no previous lot, the mix will be treated as small quantities and Standard Specification Section 403.23.7.4.1 will apply. | ||

of 4 sublots per lot. The maximum sublot size is 1000 tons. If a full lot cannot be completed, | |||

the extra sublots will be added to the previous full lot and the pay factors will be determined on the large lot. If there is no previous lot, the mix will be treated as small quantities and Standard Specification Section 403.23.7.4.1 will apply. | |||

If the target binder content is adjusted from the original JMF, a new lot shall begin. This | If the target binder content is adjusted from the original JMF, a new lot shall begin. This will ensure that the binder content pay factor will represent the population of the adjusted mix. If the cold feed settings are adjusted from the original JMF alone, a new lot is not required. Adjusting the cold feed settings will change the G<sub>sb</sub> and, therefore, the VMA of the mix. However, the VMA specification limits are based on the type of mix (see [[#Voids in the Mineral Aggregate (VMA) (Sec 403.5.4)|Voids in the Mineral Aggregate (VMA) (Sec 403.5.4)]] and do not change. The VMA is required to be within this range, even if changes are made to the JMF. A new lot sequence shall begin when a new mix design is established. The limits of adjustment can be found in Standard Specification Section 403.11. | ||

will ensure that the binder content pay factor will represent the population of the adjusted mix. If the cold feed settings are adjusted from the original JMF alone, a new lot is not required. Adjusting the cold feed settings will change the G<sub>sb</sub> and, therefore, the VMA of the mix. However, the VMA specification limits are based on the type of mix (see [[#Voids in the Mineral Aggregate (VMA) (Sec 403.5.4)|Voids in the Mineral Aggregate (VMA) (Sec 403.5.4)]] and do not change. The VMA is required to be within this range, even if changes are made to the JMF. A new lot sequence shall begin when a new mix design is established. The limits of adjustment can be found in Standard Specification Section 403.11. | |||

'''Test and Pay Factor Items''' (Sec 403.19.3) | '''Test and Pay Factor Items''' (Sec 403.19.3) | ||

Regarding Note 'b', one core equals one sample and the results will be used to determine the density pay factor for the corresponding sublot. However, if stated in the QC Plan, a maximum of two additional cores may be taken per sublot. This gives a maximum total of three cores per sublot. One core must be taken at the location selected by random numbers. The remaining cores must be taken at the same transverse offset within one foot longitudinally of the location selected by the random numbers. If more than one core is taken per sublot, all of the cores will be combined into one sample. This means that the average density of the cores will be used to determine the density pay factor for the corresponding sublot. | |||

'''Test Method Modification''' (Sec 403.19.3.1) | '''Test Method Modification''' (Sec 403.19.3.1) | ||

| Line 498: | Line 576: | ||

This specification adjusts the temperature of the binder ignition oven due to the breakdown of certain aggregate formations as a result of intense heat. | This specification adjusts the temperature of the binder ignition oven due to the breakdown of certain aggregate formations as a result of intense heat. | ||

<div id="Rice Test"></div> | |||

'''Rice Test''' (Sec 403.19.3.1.2) | '''Rice Test''' (Sec 403.19.3.1.2) | ||

If the absorption of any aggregate fraction used in the mix is greater than 2.0%, AASHTO T209 must be modified in accordance with Standard Specification Section 403.19.3.1.2. This procedure is called the dry-back method. The final surface-dry weight will be recorded in the APIW as “A2”. If necessary, the dry-back method should be performed on all samples taken in the first lot of mix produced. If the initial G<sub>mm</sub> and the dry-back G<sub>mm</sub> of a sample are within 0.002 of each other in all sublots of the first lot, the dry-back may be reduced to every | If the absorption of any aggregate fraction used in the mix is greater than 2.0%, AASHTO T209 must be modified in accordance with Standard Specification Section 403.19.3.1.2. This procedure is called the dry-back method. The final surface-dry weight will be recorded in the APIW as “A2”. If necessary, the dry-back method should be performed on all samples taken in the first lot of mix produced. If the initial G<sub>mm</sub> and the dry-back G<sub>mm</sub> of a sample are within 0.002 of each other in all sublots of the first lot, the dry-back may be reduced to every fourth sublot. Otherwise, the dry-back will be required every sublot. | ||

'''Miscellaneous Applications''' (Sec 403.19.3.2) | '''Miscellaneous Applications''' (Sec 403.19.3.2) | ||

| Line 507: | Line 585: | ||

'''Small Quantities''' (Sec 403.19.3.2.1) | '''Small Quantities''' (Sec 403.19.3.2.1) | ||

A mix that requires less than | A mix that requires less than 4000 tons on a project is referred to as small quantities. Testing frequencies will be as stated in Standard Specification Section 403.19.3.2.1(b). If a project is initially setup with less than 4000 tons, pay factors will not be determined unless an adjustment is made to the approved QC plan before production begins. If a project is initially setup with more than 4000 tons but less than 4000 tons are placed, pay factor determination is not required and Standard Specification Section 403.23.7.4.1 will apply. | ||

'''Dispute Resolution''' (Sec 403.19.4) | '''Dispute Resolution''' (Sec 403.19.4) | ||

The vast majority of issues between QC and QA can be resolved by consulting the QC Plan, the Test Method or the contract documents. Dispute decisions should always be timely and made at the lowest <u>'''appropriate'''</u> level. However, if a dispute cannot be resolved within a few hours of taking these initial steps, it should be escalated. | |||

Occasionally, the QC test may not represent the population or, due to individual differences in sampling and testing procedures, the QA and QC test results may not compare within the required limits. One of the first steps in resolution could be an immediate computation check, comparison of sampling and testing procedures, or split sample retests. Testing of the QC split sample or joint sampling and testing could determine if variations in the mix production or sampling and testing procedures are responsible for the differences. If resolution is not possible at the project level, either party may request that the approved independent third party test the mix. Third party test results will be binding upon both parties. The party whose results were incorrect will pay for the third party testing. Third party testing is costly and time consuming and should only be used when project level reconciliation is not possible. | |||

===403.1.20 Method of Measurement (Sec 403.22)=== | ===403.1.20 Method of Measurement (Sec 403.22)=== | ||

| Line 560: | Line 640: | ||

109.15. If one QA core is cut per location, that core is equal to one sample. If more than one QA core is cut per location, the test results will be averaged and those cores will equal one sample. | 109.15. If one QA core is cut per location, that core is equal to one sample. If more than one QA core is cut per location, the test results will be averaged and those cores will equal one sample. | ||

'''Smoothness Adjustment''' (Sec 403. | '''Smoothness Adjustment''' (Sec 610.5) | ||

[[image:403.1.21 Diamond Grinding.jpg|right|275px|thumb|<center>'''Diamond Grinding'''</center>]] | |||

<div id="Diamond Grinding"></div> | |||

'''Diamond Grinding''' (Sec 403.23.4.1) | '''Diamond Grinding''' (Sec 403.23.4.1) | ||

Areas of the final driving surface that must be corrected by diamond grinding will | Areas of the final driving surface that must be corrected by diamond grinding will be considered as a marred surface ([http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=9 Sec 610.5.3]). A tack coat will not be applied to these areas. No direct payment will be made for diamond grinding. | ||

No direct payment will be made for | |||

'''Tensile Strength Retained Adjustment''' (Sec 403.23.5) | '''Tensile Strength Retained Adjustment''' (Sec 403.23.5) | ||

| Line 612: | Line 692: | ||

'''Density Adjustment''' (Sec 403.23.6) | '''Density Adjustment''' (Sec 403.23.6) | ||

QC will take one unconfined longitudinal joint core per sublot, | QC will take one unconfined longitudinal joint core per sublot, as specified in the QCP. These cores will be taken within 6 in. of the unconfined longitudinal joint. Unconfined joint cores can either be located at the same longitudinal location as the corresponding mat density cores or separate | ||

random numbers can be generated. The test results for each lot will be averaged to determine | random numbers can be generated. The test results for each lot will be averaged to determine | ||

compliance with the specifications. Pay adjustments will be in accordance with the following | compliance with the specifications. Pay adjustments will be in accordance with the following | ||

| Line 619: | Line 699: | ||

{| border="1" class="wikitable" style="margin: 1em auto 1em auto" | {| border="1" class="wikitable" style="margin: 1em auto 1em auto" | ||

|- | |- | ||

!style="background:#BEBEBE"|Longitudinal Joint Density (Percent of G<sub>mm</sub>||style="background:#BEBEBE"|Pay Factor (Percent of Contract Unit Price) | !style="background:#BEBEBE"|Longitudinal Joint Density (Percent of G<sub>mm</sub>)||style="background:#BEBEBE"|Pay Factor (Percent of Contract Unit Price) | ||

|- | |- | ||

| Colspan="2" | For all SP mixtures other than SP125xSM | | Colspan="2" | For all SP mixtures other than SP125xSM | ||

|- | |- | ||

| 90.0 to 96.0 | | 90.0 to 96.0 inclusive || 100 | ||

|- | |- | ||

| 96.1 to 96.5 or 89.5 to 89.9 inclusive || 90 | | 96.1 to 96.5 or 89.5 to 89.9 inclusive || 90 | ||

| Line 650: | Line 730: | ||

|} | |} | ||

If pay reductions are necessary, the lower adjusted contract unit price of the PWL or the | If pay reductions are necessary, the lower adjusted contract unit price of the PWL or the unconfined joint density adjustment will apply to the corresponding tonnage. For example, assume that the lot size is 4000 tons and that 1000 tons in the lot has an unconfined joint. The total pay factor for the lot due to volumetric testing is 105%. A longitudinal joint core is taken as required and the pay factor due to the unconfined joint density is 90%. As a result, a 10% reduction to the contract unit price will be applied to the 1000 tons represented by the unconfined joint and a 5% bonus will be paid for the remaining tonnage in the lot (3000 tons). On the other hand, if the pay factor due to the unconfined joint density were 100%, the 5% bonus would be paid for the entire lot. Longitudinal joint density is very important and this is an attempt to ensure that density is achieved. If it is not, the joint will ravel. Longitudinal joint core density testing will be waived if the contractor elects to mill off 6” of the unconfined joint edge. | ||

unconfined joint density adjustment will apply to the corresponding tonnage. For example, | |||

assume that the lot size is 4000 tons and that 1000 tons in the lot has an unconfined joint. The | |||

total pay factor for the lot due to volumetric testing is 105%. A longitudinal joint core is taken as required and the pay factor due to the unconfined joint density is 90%. As a result, a 10% reduction to the contract unit price will be applied to the 1000 tons represented by the unconfined joint and a 5% bonus will be paid for the remaining tonnage in the lot (3000 tons). On the other hand, if the pay factor due to the unconfined joint density were 100%, the 5% bonus would be paid for the entire lot. Longitudinal joint density is very important and this is an attempt to ensure that density is achieved. If it is not, the joint will ravel. | |||

'''Percent Within Limits (PWL)''' (Sec 403.23.7) | '''Percent Within Limits (PWL)''' (Sec 403.23.7) | ||

Superpave mixes contain a quality level analysis with statistically based incentive/disincentive pay factors. The QC tests are analyzed on each lot of mix and the pay is based on the percentage of the mix that statistically falls within the limits of the specifications. It is possible to have a given lot of mix with all tests falling within the specifications, but because of a large amount of deviation between test results, the percent within limits would be very low, giving the contractor a correspondingly low pay factor. Very consistent test results, with a correspondingly low standard deviation and high percent within limits, will produce high pay factors. Test results that are consistent may produce bonus pay factors while those that fluctuate within the specification limits will produce low pay factors. | |||

The mean (x<sub>a</sub>), standard deviation (s), Upper Quality Index (Q<sub>u</sub>), Lower Quality Index(Q<sub>l</sub>), and total percent within limits (PWLt) are calculated for each pay factor item in each lot using the equations given in Standard Specification Section 403.23.7. The PWL for an item can be determined using Table III in Standard Specification Section 502.15.8. To use this table, calculate the Q<sub>u</sub> of the item and round the result to two digits (X.XX). Find the result in the left hand column of the table and move along the row to the right until reaching the column with the corresponding n-value. The n-value is the number of test results for the item in the lot. This process yields the upper percent within limits (PWL<sub>u</sub>) of the item. Repeat this process to determine the | The mean (x<sub>a</sub>), standard deviation (s), Upper Quality Index (Q<sub>u</sub>), Lower Quality Index(Q<sub>l</sub>), and total percent within limits (PWLt) are calculated for each pay factor item in each lot using the equations given in Standard Specification Section 403.23.7. The PWL for an item can be determined using Table III in Standard Specification Section 502.15.8. To use this table, calculate the Q<sub>u</sub> of the item and round the result to two digits (X.XX). Find the result in the left hand column of the table and move along the row to the right until reaching the column with the corresponding n-value. The n-value is the number of test results for the item in the lot. This process yields the upper percent within limits (PWL<sub>u</sub>) of the item. Repeat this process to determine the | ||

| Line 661: | Line 740: | ||

'''Quality Level Analysis''' (Sec 403.23.7.1) | '''Quality Level Analysis''' (Sec 403.23.7.1) | ||

Best management practice is for QA to review the QLA with QC before processing the report. Sec 403.23.7.1 requires QA to make the QLA no more than 24 hours after receipt of the contractor’s test results. | |||

'''Acceptance''' (Sec 403.23.7.1.1) | '''Acceptance''' (Sec 403.23.7.1.1) | ||

The QC test results will be used to determine the PWL as long as QC and | |||

QA compare favorably. If a favorable comparison is not obtained, dispute resolution procedures | QA compare favorably. If a favorable comparison is not obtained, dispute resolution procedures | ||

should be initiated. If dispute resolution is carried out to independent third party testing and the QC test results have been determined to be correct by the third party, the QC test results will be used to calculate the PWL. If the QA test results have been determined to be correct by the third party, the QA test results will be included in the PWL calculation. | should be initiated. If dispute resolution is carried out to independent third party testing and the QC test results have been determined to be correct by the third party, the QC test results will be used to calculate the PWL. If the QA test results have been determined to be correct by the third party, the QA test results will be included in the PWL calculation. | ||

(Sec 403.23.7 | During the project, QA and QC should be given the opportunity to witness each other’s sampling, splitting and testing. Doing so will help avoid future conflict. | ||

For comparison of QC and QA cores, the density for the QA core will be calculated using the G<sub>mm</sub> from the corresponding QC loose mix sample from the same sublot. | |||

'''Comparison''' (Sec 403.23.7.1.2) | |||

Copies of all test methods should be readily available in the field laboratory. Testing procedures must follow an approved test method. If either party has an issue with the other’s sampling, splitting or testing procedures, an objection should be raised at that time. By doing this promptly, the issue can be resolved while it is still possible to re-create the test. If a decision is made to test a retained sample, the test should be run jointly so that the testing procedure is removed as a possible variable for explaining the difference in results. | |||

A favorable comparison is obtained when the QA test results of a random, | |||

independent sample are within two standard deviations of the average of the QC test results. This determination cannot be made until all random testing for the lot has been completed. If the QC test results vary within the specification tolerances, the standard deviation will be large. In fact, as the variability in the QC test results increases, the standard deviation also increases. This results in a wide comparison range and low pay factors. On the other hand, if there is little variability in the QC test results, the standard deviation will be small. The comparison range will be narrow and the pay factors will increase. In this case, a favorable comparison is obtained when the QA test results are within one-half of the specification tolerances of the QC average. For example, the specification tolerances for VMA are –0.5% to +2.0%. One-half of this range is 1.25%. Therefore, a favorable comparison is obtained if the QA test result is within ±0.6% of the QC average. | independent sample are within two standard deviations of the average of the QC test results. This determination cannot be made until all random testing for the lot has been completed. If the QC test results vary within the specification tolerances, the standard deviation will be large. In fact, as the variability in the QC test results increases, the standard deviation also increases. This results in a wide comparison range and low pay factors. On the other hand, if there is little variability in the QC test results, the standard deviation will be small. The comparison range will be narrow and the pay factors will increase. In this case, a favorable comparison is obtained when the QA test results are within one-half of the specification tolerances of the QC average. For example, the specification tolerances for VMA are –0.5% to +2.0%. One-half of this range is 1.25%. Therefore, a favorable comparison is obtained if the QA test result is within ±0.6% of the QC average. | ||

| Line 675: | Line 763: | ||

If the QC and QA test results have been determined to be valid and the comparison is still unfavorable, the test results from the random, independent QA sample will be included in the PWL calculation. The QA test results of QC retained samples or the test results from any additional QA samples will not be used in the PWL calculation. As an example, lot 3 has been completed and consists of 4 sublots. A favorable comparison was not obtained but it was determined that the QC and QA test results are valid. Therefore, the PWL calculation will include the QC test results from all 4 of the sublots and the test results of the random, independent QA sample (n = 5). | If the QC and QA test results have been determined to be valid and the comparison is still unfavorable, the test results from the random, independent QA sample will be included in the PWL calculation. The QA test results of QC retained samples or the test results from any additional QA samples will not be used in the PWL calculation. As an example, lot 3 has been completed and consists of 4 sublots. A favorable comparison was not obtained but it was determined that the QC and QA test results are valid. Therefore, the PWL calculation will include the QC test results from all 4 of the sublots and the test results of the random, independent QA sample (n = 5). | ||

When the random QA test results are included in the PWL calculation, all volumetric properties (%AC, VMA & VA) for that sample will be used, even if only one of the three properties has an unfavorable comparison. | |||

'''Outliers''' (Sec 403.23.7.1. | For the random split sample comparisons of QC loose mix, a favorable comparison is obtained when the QA test results of a QC retained volumetric sample are within 0.010 of the QC G<sub>mm</sub> test results, within 0.010 of the QC G<sub>mb</sub> test results, and within 0.1% of the QC asphalt content test results. If larger variances occur, both QC and QA should investigate the sampling and testing procedures to identify and rectify the cause of the discrepancy. | ||

'''Outliers''' (Sec 403.23.7.1.3) | |||