616.18 Construction Inspection Guidelines for Sec 616

Traffic Control Plan (for Sec 616.1)

The traffic control plan set up in the contract is to be studied very carefully. Generally, traffic control plans are custom designed for each project. This plan is to cover all construction phases needed to construct the project, but it may be necessary to adjust it to adequately protect the public or the workers. If changes to the traffic control plans are being considered, the project designers and/or district traffic staff are to be consulted based on the magnitude of the proposed changes.

| Figures |

| Estimate Based Documentation Records |

| Worksheet |

| The MoDOT Temporary Traffic Control Inspection Worksheet |

| Approved Products Lists |

| Traffic's Approved Products List |

| More Information |

| Missouri Department of Transportation Policy for the Use of Dynamic/Changeable Message Signs |

Material (for Sec 616.2)

All traffic control devices used on a project need to meet the requirements of MoDOT and the Manual on Uniform Traffic Control Devices, (MUTCD). The MUTCD and the standard plans include drawings and dimensions for the most commonly used traffic control devices. The construction inspector is responsible to collect the required certifications for devices and materials used on the project, check devices against the approved products lists of Material's Qualified Lists and Traffic's Approved Products List, to do a visual inspection to ensure devices conform to the "MUTCD" and our specifications and are not damaged. Confirmation of this information is entered in to SiteManager. Generally certifications are required for sign sheeting and other temporary traffic control devices as described in Sec 1063.

Safety Requirements (for Sec 616.3)

For Sec. 616.3.1

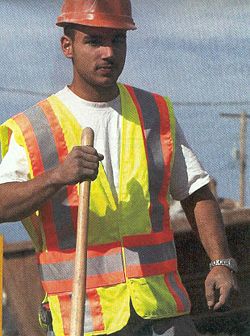

All workers within highway right of way shall wear approved ANSI/SEA 107 Performance Class 2 or 3 safety apparel, including safety glasses and safety footwear. See EPG 616.4.3 Worker Safety Considerations for worker apparel and EPG 616.5.2 High-Visibility Safety Apparel for flagger apparel. Safety apparel should consist of two material types: background and retroreflective. Background material is normally a colored fluorescent material intended to be highly conspicuous but not retroreflective. Retroreflective material should reflect light back to a light source (ex. vehicle headlights) in low light or nighttime conditions.

| Additional Safety Apparel Information |

| OSHA Rules |

| FHWA Worker Visibility Rules |

| ANSI/ISEA 107-2004 Standards |

| ANSI-ISEA 107-2004 Quick Reference |

Class 2 apparel should cover the torso area and normally consists of a vest or shirt. Class 2 apparel should consist of a minimum of 775 sq. in. of background material and at least 201 sq. in. of retroreflective material.

Class 3 apparel should provide greater visibility for the wearer and should provide a full range of body movements. Class 3 apparel normally consists of a full-sleeved top or a Class 2 vest or shirt with Class E pants. Class 3 material should consist of 1,240 sq. in. of background material with at least 310 sq. in. of retroreflective material.

All manufactured safety apparel should have a tag inside the collar stating if the apparel meets Class 2 or Class 3 requirements.

For Sec. 616.3.2

The ROAD CLOSED sign may now be placed on the Type III barricade face. The sign does not need to be placed on a separate sign support post. Placement on the barricade face will require the use of a roll-up sign, lightweight plastic sign substrates or corrugated plastic sign panel to be considered crashworthy. Metal signs are not allowed. The use of ordinary hardware snaps (two male fasteners, with screw, on each of the top two rails and a female fastener near each of the sign corners) make for an efficient means of affixing a roll-up sign, with or without its ribs, to the face of a Type III barricade, while providing an effective and safe installation.

Coldmilled areas not intended to be the final driving surface on a roadway, specifically on milling and resurfacing projects, but are opened to traffic prior to being resurfaced, may present hazardous conditions for motorcyclists and drivers of small vehicles or other passenger vehicles with certain type of tire treads. For this reason, where coarse milled surfaces are present as the driving surface, the contractor shall, at the contractor's expense, deploy advance signing on the roadway to inform motorists of this condition. The signing may be in the form of either changeable message signs (CMS) or static signs, (refer to Standard Plan 616.10). The deployment of these signs shall be located far enough in advance to allow motorists the opportunity to take an alternate route or to slow to an acceptable speed to negotiate safely through that section of roadway. Specific guidelines are as follows:

- Signing is to be present only when the milled surfaces are open to traffic.

- Signing is to be deployed in advance of an exit from the mainline prior to the milled area to allow motorists an opportunity to take an alternate route.

- Signing is also to be placed on any ramps leading into the area.

- For the mainline roadway, the recommended display on CMS boards is a two-phased message as follows:

- First Phase Message:

- GROOVED

- PAVEMENT

- XX MILES

- First Phase Message:

- Second Phase Message:

- GROOVED

- PAVEMENT

- (1)

- Second Phase Message:

- (1) This line is to be left blank if both lanes are milled. If the milled surface is in only one lane, then this line should state which lane, specifically, LT LANE ….RT LANE.

- For on-ramps or other accesses, the recommended display on CMS boards is a two-phased message as follows:

- First Phase Message:

- GROOVED

- PAVEMENT

- AHEAD

- First Phase Message:

- Second Phase Message:

- GROOVED

- PAVEMENT

- (2)

- Second Phase Message:

- (2) This line is to be left blank if both lanes are milled. If the milled surface is in only one lane, then this line should state which lane, specifically, LT LANE ….RT LANE.

The deployment of this signing is to be limited. Although not a contract requirement, on most milling and resurfacing projects, the resurfacing operation follows closely behind the milling operation. However, this condition may be present when the contractor elects to do otherwise or when weather conditions stop operations prior to finishing the resurfacing of milled areas.

For Sec. 616.3.3

All traffic control devices used on a project must also be NCHRP 350 compliant. Documentation of compliancy for NCHRP 350 is required for each type of device and needs to be placed in the project files. Small items like channelizers are self-certified by the manufacturer. Larger devices such as sign stands, barricades, etc. require an FHWA acceptance letter. The FHWA identifies their acceptance letters with a “WZ” number

For Sec 616.3.4

When the contract requires the contractor to designate a trained person at the project level with the primary responsibility for implementing the traffic management plan and other safety and mobility aspects of the project, the name of that person and proof, as required by the contract documents, should be provided by the contractor prior to work starting on that project, preferably at the preconstruction meeting.

Construction Requirements (for Sec 616.4)

When determining the appropriate location to install traffic control devices, consider the location of trees, sidewalks, billboards, commercial signs, etc. that may obscure the visibility of the devices. Minor adjustments to locations shown on the plans may be made to accommodate existing site conditions prior to installation.

Once in place, traffic control devices are to be clearly identified in SM using the DWR Template for Construction Signs. When access to SM is not immediately available, documentation may be recorded in a bound field book, signed by the inspector making the entry, and later entered into SM. Identification of traffic control devices is necessary to avoid duplicate payment. Identification can be made by location (Sta, Log mile, GPS, etc.) or other descriptions that distinguish that device from all others. For example, it would be acceptable to identify a group of Road Work Ahead signs by stating, “Seven Road Work Ahead signs installed today on each of the seven county road approaches on Rte. J”. Portable sign packages can be identified as groups, for example, “Six sets of portable sign packages for flagger control were authorized today on Rte. 24, three sets were used for the cold milling operation and three sets were used for the asphalt operation”. Significant changes or additions to the traffic control plan should be documented. Adjusting the location of signs to improve visibility or effectiveness would not be considered a significant change. The final quantity of traffic control devices should reflect the maximum amount of authorized devices that were in place at any point in time, thus avoiding duplicate payment for devices that are relocated or used multiple times. All temporary traffic control devices should be authorized by documentation record![]() . Documentation records are created to document temporary traffic control devices that are normally removed or covered up as construction progresses (with the exception of permanent pavement marking). It is important to issue the documentation record promptly to let the contractor know what is going to be paid while the temporary devices are still in place so that if the contractor has a dispute the issue can be resolved before the device is removed or changed. Therefore, the documentation record is created automatically as a part of the contractor’s payment estimate when the estimate is generated and can be sent to the contractor at that time.

. Documentation records are created to document temporary traffic control devices that are normally removed or covered up as construction progresses (with the exception of permanent pavement marking). It is important to issue the documentation record promptly to let the contractor know what is going to be paid while the temporary devices are still in place so that if the contractor has a dispute the issue can be resolved before the device is removed or changed. Therefore, the documentation record is created automatically as a part of the contractor’s payment estimate when the estimate is generated and can be sent to the contractor at that time.

Additional documentation, such as videotape, may also be considered depending on the location and project. Videotapes are to be considered at the start of the construction project and each time a significant change occurs in the traffic control or when a new stage of the traffic control plan is implemented.

Speed limits: Refer to EPG 616.29 Work Zone Speed Limits for guidance on setting work zone speed limits.

For Sec 616.4.1

It is very important to continually check temporary traffic control devices to see that they are adequate, kept in good repair, clean and covered, set aside or removed when no longer needed. Make sure any permanent traffic control devices in conflict with the temporary traffic control devices (such as speed limit signs) are covered or removed. Frequent nighttime inspections are to be made to ensure that the devices have the proper reflectivity or lighting so they are visible and meaningful to the traveling public. Refer to the Quality Standards for Temporary Traffic Control Devices for further guidance. The MoDOT Temporary Traffic Control Inspection Worksheet provides a checklist that the inspector may find helpful when inspecting work zones.

According to Standard Plan 616.10, the mounting height for Type 2 portable signs may be 12 in. when the installation is for three days or less. This means that Type 2 portable signs may be used on work zones that the location varies from day to day and does not occupy the same location for more than three consecutive days, such as asphalt paving operations, guardrail installations, diamond grinding, etc. In such cases, the project may be ongoing for months, but the work zone locations moves up and down the roadway and do not occupy the same location from day to day.

For Sec 616.4.1.1

Although there is not a safety issue with stowing along the side of the roadway temporary traffic control products such as channelizers, the contractor should stow them in an orderly manner to be appeasing to the driving public.

Leaving equipment running on the shoulders with no workers present or having equipment running with an operator present, but with no intent to do work, should be considered as non-construction hours. In accordance with Secs 107.5.3 and 616.4.1.1 of the standard specifications, the equipment is to be removed and all work zone devices to be removed or covered. The exception would be when the roadway must be kept closed for other reasons, such as the concrete in pavement repairs to gain strength, asphalt to cool to allowable temperatures, pavement marking material to cure/dry, etc.

For Sec 616.4.2

With the exception of contract overlays on two-lane highways and a few other exceptions, MoDOT’s construction contracts traditionally specify and include pay quantities for only one set of lane drop signs. The reason is that in the design stage it has not been determined how the contractor will pursue the work, so the sets of signs are kept to a minimum to avoid adding unneeded costs to a project. However, for diamond grinding, asphalt overlays and similar work on divided highways it makes good sense to allow the contractor to provide an additional set of signs to expedite the work. Additional signs approved by the engineer to adequately protect the public and the work, or to expedite the work, the contractor should be reimbursed in accordance with Sec. 616.4.2.3.

Deficiencies in Traffic Control Measures (For Sec 616.4.2.5)

The timeframe for correcting deficiencies in traffic control is based on the exposure. The exposure can be viewed as the danger the deficiency presents to travelers, the workers or the work site. The inspector must use good judgment to determine the severity of the exposure. To help determine the severity of the exposure, categories of severity of exposure have been established and implemented into the standard specifications.

Criteria for enforcement has been provided as well and needs to be strictly enforced as outlined in Sec 616.4.2.5. The intent of the specification is for the contractor to provide quality control of traffic control devices and to maintain a safe work zone environment. The contractor should monitor the work zone area as needed or agreed upon to identify and correct traffic control deficiencies. MoDOT is to provide quality assurance. The engineer or inspector verbally or in writing notifies the contractor of the deficiency when a traffic control deficiency is observed, in accordance with Sec 616.4.2.5.

The timeframes to correct deficiencies should conform as closely as possible to those provided within the specifications. In the case of extensive deficiencies or unavailability of necessary material to correct a deficiency, such as may occur when a truck wipes out multiple signs and other work zone devices, the engineer may need to alot additional time to the contractor. During the initial notification, the engineer and contractor should mutually agree on both what is to be accomplished and when to rectify a deficiency. This mutual agreement and good, continuous communication between the contractor and engineer establishes what the specifications refer to as a good faith effort.

If the contractor does not correct the deficiency within the timeframe as agreed upon with the engineer after the initial notification, an order record is issued and the contractor is given the allocated time period as stated in the specification.

According to Sec 616.4.2.5.3, if the contractor does not correct the deficiency by the timeframe set in Sec 616.4.2.5.2, the engineer may issue a second order record or suspend the work in accordance with Sec 105.

In accordance with Sec 616.4.2.5.4, when the contractor is not adequately providing quality control and the contractor is continuously being notified of similar, reoccuring deficiencies, the steps outlined in Sec 616.4.2.5.2 may be bypassed and an order record and subsequent order records may be issued by the engineer in accordance with Sec 616.4.2.5.3. Prior to this, the contractor should be made aware that these provisions will be implemented if the contractor’s quality control does not improve. At the time of such notification, which may be verbal but is recommended to be documented in writing, the contractor and the engineer should mutually agree on what actions the contractor needs to take to avoid issuance of order records in accordance with Sec 616.4.2.5.4.

Implementing Sec 105 should be a last resort. Before such action is taken, the Resident Engineer should be consulted.

Flagger Requirements (for Sec 616.4.3)

Flagger certifications are to be verified. Acceptable certification agents include American Traffic Safety Services Association (ATSSA), National Safety Council, AGC, in-house training programs, etc. Each flagger is to have stop/slow paddle and a two-way radio or walkie-talkie.

For daytime activities, flaggers shall wear a high visibility hard hat, safety glasses, a Performance Class 3 top OR a Performance Class 2 top, and safety footwear. Hard hats other than high visibility orange or green shall be covered with a high visibility covering. For nighttime activities, flaggers shall wear a high visibility/reflective hard hat, safety glasses, a Performance Class 3 top AND Class E bottoms OR a Performance Class 2 top AND Class E bottoms and safety footwear. Hard hats shall be reflective or covered with a high visibility covering. All high visibility and retroreflective safety apparel shall be designed to clearly identify the wearer as a person. Also, see EPG 616.5.2 High-Visibility Safety Apparel.

All flagger stations need to be lit during nighttime operations.

The pilot vehicle operator needs to be certified as a flagger and certification is to be verified. The pilot vehicle needs to be equipped with a communication device, the “Pilot Car Follow Me” sign and a warning light. The access control and signing for each side road located within the work area of the one-lane, two-way operation should be determined as discussed in EPG 616.3.10.1. Where applicable, the signing sequence for the side road should be supplemented with the “Please Wait for Pilot Car” sign.

The Automated Flagger Assistance Device (AFAD) operator needs to be certified as a flagger and certification should be verified. The AFAD should be the Type B (Red/Yellow Lens). For typical AFAD applications, refer to EPG 616.5.5 and TA-10a.

The Portable Signal Flagging Device (PSFD) operator needs to be certified as a flagger and certification should be verified. For typical PSFD applications, refer to TA-10c.

Law Enforcement (for Sec 616.4.4)

When law enforcement is specified in the contract, the engineer and contractor should review the contractor’s working hours and work schedule and decide upon the best times for law enforcement to be effective. The engineer is responsible for coordinating with local law enforcement.

The preconstruction meeting will be used to communicate the details of the traffic control plan and how law enforcement activities can best complement this plan. These details include the type of enforcement, the location within the work zone where the enforcement is intended to occur and the schedule.

At the preconstruction meeting, the engineer, contractor and law enforcement agencies should finalize the expectations of times, schedules, scope and logistics of projects. Payment to law enforcement will be made through the Commission.

Lighting Requirements (for Sec 616.5)

The contractor should submit work zone lighting plans two weeks prior to construction. It is recommended that the inspector consult district traffic personnel to help review lighting plans and to make any recommended changes. Typical work zone lighting may include dirigible lighting, portable light towers, balloon lighting, lights attached to equipment or post-mounted lights. In some cases, existing lighting or ambient lighting may meet lighting level requirements. The inspector may wish to check lighting levels with a photometric light meter if there are any questions or concerns about the light being provided. Check to make sure that all construction vehicles and equipment required to have warning lights have them activated while in the work zone. Work zone lighting is included as a pay item when the contract documents mandate that the work is to be done at night. If the contractor opts to do work at night, then a contract price may be negotiated if it is determined that working at night is in the best interest of the motoring public and/or the Department. Regardless if work zone lighting is specified in the contract or not, all lighting needs to be in accordance with the specifications.

If temporary lighting is specified in the contract, consult the plans for installation and EPG 901.16 Construction Inspection Guidelines for Sec 901 for guidance on inspection.

Flashing Arrow Panels (for Sec 616.6)

Proposed locations are to be verified for visibility and sight distance. Depending on geometrics and traffic conditions such as curves, hills, traffic back ups, etc., it may be necessary to relocate flashing arrow panels.

Changeable Message Signs (for Sec 616.7)

It is important to verify that the changeable message sign (CMS) is installed according to Standard Plan 616.10. It may be necessary to make minor adjustments or temporary modifications to the location to meet these requirements if the proposed location is in a ditch, driveway, guardrail, sidewalk, rock cut, etc.

Changeable message signs need to be operated in accordance with the Missouri Department of Transportation Policy for the Use of Dynamic/Changeable Message Signs. The CMS is not to be used to repeat static sign messages. The flash rate should be checked to see that motorists are able to read the sign as they approach the work zone. When not in use, the CMS needs to be turned away from traffic or removed from the roadway if it will not be required for more than 24 hours. A document log needs to be maintained in the inspector’s diary on when and what messages are displayed on CMS, to include when no messages were shown.

Work Zone Traffic Signals (for Sec 616.8)

When traffic signals are specified in the contract, the contractor will provide the timing plan for approval and will also provide whatever detection they feel will best fit the situation. District traffic is to be consulted to help review timing plans and detection zones. Overhead lighting must be provided at each signal location.

Basis of Payment (for Sec 616.10)

There are many items of work that are considered incidental. These incidental items should not have a pay item included in the plans since their cost is included in the larger activity they are associated with.

Devices requiring corrective action or repairs due to the contractor’s operations or normal wear and tear are not reimbursable. Where the contractor has received approval for the installation of additional devices due to omissions in the plans, field conditions or extenuating circumstances, quantities should be adjusted and reimbursement provided to the contractor. If necessary, a price should be negotiated for devices not originally covered in the contract. If the contractor receives approval for the installation of additional devices solely for the benefit of their operation, reimbursement is not made.

Refer to Sec 616.10 for a complete listing of items typically not paid for.

Relocation of Service Signs (Logo Signs) on Construction Projects

The following guidance details the process for addressing any modification or relocation (temporary or permanent) of Logo Signs and/or Tourist Oriented Destination Signs (TODS) during a STIP construction project.

Logo signs and TODS are owned by MoDOT, but these programs are managed by a contractor to maximize the participation. While the Logo contractor is responsible for all normal operating costs associated with these programs, they are not responsible for the cost to relocate or modify the signs when that becomes necessary due to a MoDOT construction project. This guidance ensures the Logo contractor is properly notified and reimbursed for the relocations and the cost is charged to the STIP project. This process does not apply to Local Public Agency (LPA) projects. Since vendors are paying to display these signs, the signs must remain visible throughout the construction project (i.e., they should not just be removed at the beginning of the project and reinstalled at the end). When feasible, the designer should include the locations of the temporary and permanent position of these signs in the plans.

Below is the General Provisions verbiage that outlines the contractual requirements of this process:

- SERVICE SIGNING

- 1.0 Description. All installation, relocation and repair of Missouri LOGO, Tourist Oriented Destination Signs (TODS) and General Service Signing shall be coordinated between the engineer, contractor and the designated Missouri LOGO representative.

- 1.1 It shall be noted by the contractor that Missouri LOGOS is responsible for the installation, relocation and repair of all LOGO, TODS and General Service Signs on MoDOT owned right of way. The contractor shall be solely responsible and liable for determining any impact to LOGO, TODS or General Service Signing due to contractor operations during construction of this contract. The contractor shall be responsible for notifying Missouri LOGOS at the time of the preconstruction meeting when a service sign is determined to be impacted and advise Missouri LOGOS of the project details. The Missouri LOGO representative will attend these meetings at their discretion.

- The Missouri LOGO representative shall be contacted 24 hours a day, 7 days per week at (573) 291-6788.

- 1.2 Missouri LOGOS will be responsible for any installation or relocation of service signs necessary for this contract. If Missouri LOGO's has to perform work within the limits of the project, Missouri LOGOS will conduct work so as not to interfere with or hinder the progress or completion of the work being performed by the contractor. Full cooperation of the contractors involved, in careful and complete coordination of their respective activities in the area, will be required.

- 2.0 Basis of Payment. No direct payment will be made to the contractor to recover the cost of equipment, labor, materials or time required to fulfill this provision.

Steps for relocating Logo signs and TODS on a construction project:

- 1. Per the requirements of the General Provision, the STIP project contractor shall invite Missouri Logo to the Pre-construction Conference, as well as all Progress Meetings that include discussion of work that will affect the display of the logo signs.

- 2. The STIP project contractor shall coordinate the work with the Missouri Logo contractor, including notification of any schedule changes.

- 3. Missouri Logo will then schedule their contractor to perform the relocation without causing delay to the STIP project.

- 4. The Resident Engineer (RE), or assigned staff, should request an invoice from the Missouri Logo contractor for the sign relocation work. The prices shown on the invoice should not exceed the agreed upon unit prices in our contract with Missouri Logo (refer to the Unit Pricing table).

- 5. The RE should review the invoice to verify the quantities and unit prices are correct.

- 6. The RE should submit the approved invoice and Job Number to the District Support Services Manager for payment. The District Support Services Manager will process payment directly to the Missouri Logo contractor and charge the expense to the STIP project.

- 7. This is a non-contractual cost; therefore it will not be reflected on the final payment estimate in Sitemanager. For cost share projects, if the district feels this amount is significant, it will need to be added to the total project cost shown on the final payment estimate when calculating the total cost share amount.