751.36 Driven Piles

751.36.1 General

Accuracy Required

All capacities shall be taken to the nearest 1 (one) kip, loads shown on plans.

751.36.1.1 Maximum Specified Pile Lengths

Structural Steel Pile No Limit Cast-In-Place (CIP) (Welded or Seamless Steel Shell (Pipe)) Pile No Limit

It is not advisable to design pile deeper than borings. If longer pile depth is required to meet design requirements, then request Geotechnical Section to provide deeper borings or increase the number of piles which will reduce load per pile as well as required pile length.

751.36.1.2 Probe Pile

| Asset Management |

| Report 2009 |

| See also: Innovation Library |

Length shall be estimated pile length + 10’.

When probe piles are specified to be driven-in-place they shall not be included in the number of piles indicated in the “FOUNDATION DATA” Table.

751.36.1.3 Static Load Test Pile

When Static Load Test Pile is specified, the nominal axial compressive resistance value shall be determined by an actual static load test.

For preboring for piles see Sec 702.

751.36.1.4 Preliminary Geotechnical Report Information

The foundation can be more economically designed with increased geotechnical information about the specific project site.

Soil information should be reviewed for rock or refusal elevations. Auger hole information and rock or refusal data are sufficient for piles founded on rock material to indicate length of piling estimated. Standard Penetration Test information is especially desirable at each bent if friction piles are utilized or the depth of rock exceeds approximately 60 feet.

751.36.1.5 Geotechnical Redundancy

Pile Nonredundancy (20 percent resistance factor reduction)

Conventional bridge pile foundations:

For pile cap footings where a small pile group is defined as less than 5 piles, reduce pile geotechnical and structural resistance factors shown in LRFD Table 10.5.5.2.3-1.

For pile cap bents, the small pile group definition of less than 5 piles is debatable in terms of nonredundancy and applying a resistance factor reduction. The notion of a bridge collapse or a pile cap bent failure directly related to the failure of a single pile or due to its pile arrangement in this instance, or ignoring the strength contribution of the superstructure via diaphragms in some cases would seem to challenge applying the small pile group concept to pile bent systems as developed in NCHRP 508 and alluded to in the LRFD commentary. In terms of reliability, application of this factor could be utilized to account for exposed piling subject to indeterminable scour, erosion, debris loading or vehicular impact loadings as an increased factor of safety.

For integral and non-integral end bent cap piles, the reduction factor need not be considered for less than 5 piles due to the studied infrequency of abutment structural failures (NCHRP 458, p. 6) and statewide satisfactory historical performance.

For intermediate bent cap piles, the reduction factor need not be considered for less than 5 piles under normal design conditions. It may be considered for unaccountable loading conditions that may be outside the scope of accountable strength or extreme event limit state loading and is specific to a bridge site and application and is therefore utilized at the discretion of the Structural Project Manager or Structural Liaison Engineer. Further, if applied, it shall be utilized for determining pile length if applicable, lateral and horizontal geotechnical and structural resistances. Alternatively, a minimum of 5 piles may save consideration and cost.

Any substructure with a pile foundation can be checked for structural redundancy if necessary by performing structural analyses considering the hypothetical transference of loads to presumed surviving members of a substructure like columns or piles (load shedding). This direct analysis procedure could be performed in place of using a reduction factor for other than pile cap footings.

For nonconventional bridges like major bridges and major river and lake bridges, the application of pile redundancy may take a more strict direction. See the Structural Project Manager or Structural Liaison Engineer.

751.36.1.6 Waterjetting

| Commentary on Waterjetting |

Waterjetting is a method available to contractors to aid in driving piles. If the drivability analysis indicates difficulty driving piles then it can be assumed that the contractor may use waterjetting to aid in driving the piles. The Commentary on Waterjetting discusses items to consider when there is a possibility of the use of waterjetting.

751.36.1.7 Restrike

In general, designers should NOT require restrikes unless the Geotechnical Section requires restrike because it delays construction and makes it harder for contractors to estimate pile driving time on site. The Geotechnical Section shall show on borings data a statement indicating either "No Restrike Recommended" or "Restrike Recommended", with requirements.

751.36.2 Steel Pile

751.36.2.1 Material Properties

751.36.2.1.1 Structural Steel HP Pile

Structural Steel HP piling shall be ASTM A709 Grade 50S (fy = 50 ksi) steel.

751.36.2.1.2 Cast-In-Place (CIP) Pile

Welded or Seamless steel shell (Pipe) for CIP piling shall be ASTM 252 Grade 3

- (fy = 45 ksi, Es = 29,000 ksi)

Concrete

| Class B - 1 Concrete (Substructure) | = 4.0 ksi |

Modulus of elasticity,

Where:

- f'c in ksi

- wc = unit weight of nonreinforced concrete = 0.145 kcf

- K1 = correction factor for source of aggregate

- = 1.0 unless determined by physical testing

Reinforcing Steel

| Minimum yield strength, | = 60.0 ksi | |

| Steel modulus of elasticity, | = 29000 ksi |

751.36.2.2 Steel Pile Type

Avoid multiple sizes and/or types of pilings on typical bridges (5 spans or less). Also using same size and type of pile on project helps with galvanizing.

There are two types of piles generally used by MoDOT. They are structural steel HP pile and close-ended pipe pile (cast-in-place, CIP). Open ended pipe pile (cast-in-place, CIP) can also be used. Structural steel piling are generally referred to as HP piling and two different standard AISC shapes are typically utilized: HP12 x 53 and HP14 x 73. Concrete piling are generally referred to as cast-in-place or CIP piling because the concrete is poured and cast in steel shells which are driven first or pre-driven.

751.36.2.2.1 Structural Steel HP Pile

| Section | Area | |

|---|---|---|

| HP 12 x 53 | 15.5 sq. in. | |

| HP 14 x 73 | 21.4 sq. in. |

The HP 12 x 53 section should generally be used unless a heavier section produces a more economical design or required by a Drivability Analysis.

751.36.2.2.2 Cast-In-Place (CIP) Pile

| Outside Diameter | Minimum Nominal Wall Thickness |

Common Available Nominal Wall Thicknesses |

|---|---|---|

| 14 inch | 1/4” | 1/4”, 3/8”, 1/2” and 5/8”2 |

| 16 inch | 1/4” | 1/4”, 3/8”, 1/2” and 5/8”2 |

| 20 inch1 | 1/4” | 1/4”, 3/8”, 1/2” and 5/8” |

| 24 inch1 | 3/8” | 3/8”, 1/2”, 5/8” and 3/4” |

| 1 Use when required to meet KL/r ratio or when smaller diameter CIP do not meet design. | ||

| 2 5/8” wall thickness is less commonly available than the smaller wall thicknesses of pipe pile. | ||

Use minimum nominal wall thickness which is preferred. When this wall thickness is inadequate for structural strength or for driving (drivability), then a thicker wall shall be used. Specify the required wall thickness. The contractor shall determine the pile wall thickness required to avoid damage during driving or after adjacent piles have been driven, but not less than the minimum specified.

Minimum tip elevation must be shown on plans. Criteria for minimum tip elevation shall also be shown. The following information shall be included on the plans:

- “Minimum Tip Elevation is required _______________.” Reason must be completed by designer such as:

- for lateral stability

- for required tension or uplift pile capacity

- to penetrate anticipated soft geotechnical layers

- for scour*

- to minimize post-construction settlements

- for minimum embedment into natural ground

- *For scour, estimated maximum scour depth (elevation) must be shown on plans.

- Guidance Note: Show maximum of total scour depths estimated for multiple return periods in years from Preliminary design which should be given on the Design Layout. Show the controlling return period (e.g. 100, 200, 500). If return periods are different for different bents, add a new line in foundation data table.

751.36.3 Pile Point Reinforcement

Pile point reinforcement is also known as a pile tip (e.g., pile shoe or pile toe attachments).

751.36.3.1 Structural Steel HP Pile

Pile point reinforcement shall be required for all HP piles required to be driven to bear on rock regardless of pile strength used for design loadings or geomaterial (soils with or without gravel or cobbles) to be penetrated. Pile point reinforcement shall be manufactured in one piece of cast steel. Manufactured pile point reinforcements are available in various shapes and styles as shown in FHWA-NHI-16-010, Figure 16-5.

751.36.3.2 Cast-In-Place (CIP) Pile

For CIP piles, use pile point reinforcement if boulders or cobbles or dense gravel are anticipated.

Geotechnical Section shall recommend when pile point reinforcement is needed and type of pile point reinforcement on the Foundation Investigation Geotechnical Report.

For Closed Ended Cast-In-Place Concrete Pile (CECIP)

Two types are available.

- 1. “Cruciform” type should be used as recommended and for hard driving into soft rock, weathered rock, and shales. It will continue to develop end bearing resistance while driving since an exposed flat closure plate is included with this point type. The closure plate acts to distribute load to the pile cross sectional area.

- 2. “Conical” type should be used as recommended and when there is harder than typical driving conditions, for example hard driving through difficult soils like heavily cobblestoned, very gravelly, densely layered soils. Severely obstructed driving can cause CIP piles with conical points to deflect. Conical pile points are always the more expensive option.

For Open Ended Cast-In-Place Concrete Pile (OECIP)

One type is available.

- “Open Ended Cutting Shoe” type should be used as recommended and when protection of the pipe end during driving could be a concern. It is also useful if uneven bearing is anticipated since a reinforced tip can redistribute load and lessen point loading concerns.

- Open ended piles are not recommended for bearing on hard rock since this situation could create inefficient point loading that could be structurally damaging.

When Geotechnical Section indicates that pile point reinforcement is needed on the boring log, then the recommended pile point reinforcement type shall be shown on the plan details. Generally this information is also shown on the Design layout.

For pile point reinforcement detail, see

| Bridge Standard Drawings |

| Pile |

751.36.4 Anchorage of Piles for Seismic Categories B, C and D

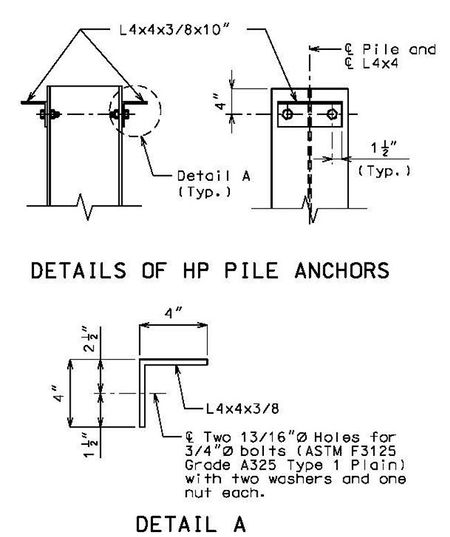

751.36.4.1 Structural Steel HP Pile - Details

Use standard seismic anchorage detail for all HP pile sizes. Modify detail (bolt size, no. of bolts, angle size) if seismic and geotechnical analyses requires increased uplift resistance. Follow AASHTO 17th Ed. LFD or AASHTO Guide Specifications for LRFD Seismic Bridge Design (SGS).

- Note: Galvanizing ∟4x4, ¾” diameter bolts, (ASTM F3125 Grade A325 Type 1 Plain), washers and nuts will not be required.

751.36.4.2 Cast-In-Place (CIP) Pile - Details

| Bridge Standard Drawings |

| Pile |

751.36.5 Design Procedure

- Structural Analysis

- Geotechnical Analysis

- Drivability Analysis

751.36.5.1 Design Procedure Outline

- Determine foundation load effects from the superstructure and substructure for Service, Strength and Extreme Event Limit States.

- If applicable, determine scour depths, liquefaction information and pile design unbraced length information.

- Determine if downdrag loadings should be considered.

- Select preliminary pile size and pile layout.

- Perform a Static Pile Soil Interaction Analysis. Estimate Pile Length and pile capacity.

- Based on pile type and material, determine Resistance Factors for Structural Strength ( and ).

- Determine:

- Maximum axial load effects at toe of a single pile

- Maximum combined axial & flexural load effects of a single pile

- Maximum shear load effect for a single pile

- Uplift pile reactions

- Determine Nominal and Factored Structural Resistance for single pile

- Determine Structural Axial Compression Resistance

- Determine Structural Flexural Resistance

- Determine Structural Combined Axial & Flexural Resistance

- Determine Structural Shear Resistance

- Determine method for pile driving acceptance criteria

- Determine Resistance Factor for Geotechnical Resistance () and Driving Resistance ().

- If other than end bearing pile on rock or shale, determine Nominal Axial Geotechnical Resistance for pile.

- Determine Factored Axial Geotechnical Resistance for single pile.

- Determine Nominal pullout resistance if pile uplift reactions exist.

- Check for pile group effects.

- Resistance of Pile Groups in Compression

- Check Drivability of all pile (bearing and friction pile) using the Wave equation (GRLWEAP).

- Review Static Pile Soil Interaction Analysis and pile lengths for friction pile.

- Show proper Pile Data on Plan Sheets (Foundation Data Table).

751.36.5.2 Structural Resistance Factor (ϕc and ϕf) for Strength Limit State, LRFD 6.5.4.2

The structural resistance factor for axial resistance in compression is dependent upon the expected driving conditions. When the pile is subject to damage due to severe driving conditions where use of pile point reinforcement is necessary:

- Steel Shells (Pipe): = 0.60

- HP Piles: = 0.50

When the pile is subject to good driving conditions where use of pile point reinforcement is not necessary:

- Steel Shells (Pipe) Piles: = 0.70

- HP Piles: = 0.60

For HP piles, pile point reinforcement is always required when HP piles are anticipated to be driven to rock and proofed. Driving HP piles to rock is considered severe driving conditions for determination of structural resistance factor. However, driving HP piles through overburden not likely to impede driving to deep rock or preboring to rock for setting piles are two situations that could be considered as less than severe. Further, driving any steel pile through soil without rubble, boulders, cobbles or very dense gravel could be considered good driving conditions for determination of structural resistance factor. Consult the Structural Project Manager or Structural Liaison Engineer.

The structural resistance factor for combined axial and flexural resistance of undamaged piles:

- Axial resistance factor for HP Piles: = 0.70

- Axial resistance for Steel Shells (Pipe): = 0.80

- Flexural resistance factor for HP Piles or Steel Shells: = 1.00

For Extreme Event Limit States see LRFD 10.5.5.3.

751.36.5.3 Geotechnical Resistance Factor (ϕstat) and Driving Resistance Factor (ϕdyn), LRFD Table 10.5.5.2.3-1

The factors for Geotechnical Resistance () and Driving Resistance () will usually be different because of the different methods used to determine the nominal bearing resistance. Caution should be used if the difference in factors for Geotechnical Resistance and Driving Resistance are great as it can lead to issues with pile overruns. Also see EPG 751.36.5.9.

Geotechnical Resistance Factor, :

The Geotechnical Resistance factor is based on the static method used by the designer in determining the nominal bearing resistance. Unlike the Driving Resistance factor the Geotechnical Resistance factor can vary with the soil layers. If Geotechnical Resistance factors are not provided by the Geotechnical Engineer, values may be selected from LRFD Table 10.5.5.2.3-1. For Extreme Event Limit States see LRFD 10.5.5.3.

Driving Resistance Factor, :

The Driving Resistance factor shall be selected from LRFD Table 10.5.5.2.3-1 based on the method to be used in the field during construction to verify nominal axial compressive resistance.

| Method | Resistance Factor, |

|---|---|

| FHWA-modified Gates Dynamic Pile Formula (End of Drive condition only) |

0.40 |

| Wave Equation Analysis | 0.50 |

| Dynamic Testing on 1 to 10% piles | 0.65 |

| Other methods | Refer to LRFD Table 10.5.5.2.3-1 |

Use EPG 751.50 Standard Detailing Note G7.3 on plans as required. This requirement shall apply to any type of rock meaning weak to strong rock including stronger shales where HP piling is anticipated to meet refusal.

FHWA-modified Gates Dynamic Pile Formula is not considered accurate for pile loading (Minimum Nominal Axial Compressive Resistance) exceeding 600 kips. When pile loading exceeds 600 kips, use wave equation analysis, dynamic testing or other method.

Dynamic Testing is recommended for projects with friction piles.

751.36.5.4 Downdrag and Losses to Geotechnical Resistance due to Scour and Liquefaction (kips), LRFD 10.7.3.6, 10.7.3.7, and AASHTO Guide Specifications for LRFD Seismic Bridge Design (SGS) 6.8

Downdrag, liquefaction and scour all reduce the available skin friction capacity of piles. Downdrag is unique because it not only causes a loss of capacity, but also applies a downward force to the piles. This is usually attributed to embankment settlement. However, downdrag can also be caused by a non-liquefied layer overlying a liquefied layer. Review geotechnical report for downdrag and liquefaction information.

751.36.5.5 Preliminary Structural Nominal Axial Design Capacity (PNDC) of an individual pile (kips)

The PNDC equations provided herein assume the piles are continually braced. This assumption is applicable for the portion of piling below ground or confined by solid wall encasement. If designing a pile bent structure, scour exists or liquefaction exists then the pile shall be checked considering the appropriate unbraced length.

Structural Steel HP Piles

- Since we are assuming the piles are continuously braced, then = 0.

is the yield strength of the pile is the area of the steel pile

Welded or Seamless Steel Shell (Pipe) Cast-In-Place Piles (CIP Piles)

is the yield strength of the pipe pile is the area of the steel pipe (deducting 12.5 % ASTM tolerance and 1/16 inch corrosion where appropriate.) is the concrete compressive strength at 28 days is the area of the concrete inside the pipe pile

- Maximum Load during pile driving =

Welded or Seamless Steel Shell shall be ASTM 252 Grade 3 (45 ksi). ASTM 252 states “the wall thickness at any point shall not be more than 12.5% under the specified nominal wall thickness.” AASHTO recommends deducting 1/16” of the wall thickness due to corrosion (LRFD 5.13.4.5.2). Corrosion need not be considered at construction stage and for drivability analysis and driven analysis. For drivability analysis and driven analysis deduct 12.5% of specified nominal wall thickness (ASTM A252). For structural design deduct 12.5 % (ASTM A252) and 1/16” for corrosion (LRFD 5.13.4.5.2) from specified nominal wall thickness.

751.36.5.6 Preliminary Factored Axial Design Capacity (PFDC) of an Individual Pile (kips)

- PFDC = Structural Factored Axial Compressive Resistance – Factored Downdrag Load

751.36.5.7 Design Values for Steel Pile

751.36.5.7.1 Design Values for Individual HP Pile

Fy = 50 ksi. End Bearing Piles (HP piles) anticipated to be driven to rock.

| Pile Size | As Area, sq. in. |

Structural Nominal Axial Compressive Resistance PNDC1,2, kips |

Φc Structural Resistance Factor4, LRFD 6.5.4.2 |

Structural Factored Axial Compressive Resistance2,3,4, kips |

0.9*ϕda*Fy Maximum Nominal Driving Stress, LRFD 10.7.8, ksi |

|---|---|---|---|---|---|

| HP 12x53 | 15.5 | 775 | 0.5 | 388 | 45.00 |

| HP 14x73 | 21.4 | 1070 | 0.5 | 535 | 45.00 |

| 1 Structural Nominal Axial Compressive Resistance for fully embedded piles only. Structural Nominal Axial Compressive Resistance for unsupported piles shall be determined in accordance with LRFD 10.7.3.13.1. (i.e., intermediate pile cap bent). Minimum Nominal Axial Compressive Resistance = Required nominal driving resistance, Rndr = (Maximum factored axial loads / ϕdyn) ≤ Structural nominal axial compressive resistance, PNDC LRFD 10.5.5.2.3 2 Axial Compressive Resistance values shown above shall be reduced when downdrag is considered

| |||||

751.36.5.7.2 Design Values for Individual Cast-In-Place (CIP) Pile

Grade 3 Fy = 45 ksi; F'c = 4 ksi; Structural Resistance Factor, (Φc)1 = 0.6

| Unfilled Pipe For Axial Analysis2 | Concrete Filled Pipe For Flexural Analysis3 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pile Outside Diameter O.D., in. | Pile Inside Diameter I.D., in. | Minimum Wall Thickness, in. |

Reduced Wall thick. for Fabrication (ASTM 252), in. |

As,4 Area of Steel Pipe, sq. in. |

Structural Nominal Axial Compressive Resistance, Pn5,6,7,8, kips |

Structural Factored Axial Compressive Resistance1,8,9, kips |

0.9*ϕda*Fy*As Maximum Nominal Driving Resistance6,7, LRFD 10.7.8, kips |

Reduced Wall Thick. for Corrosion (1/16"), LRFD 5.13.4.5.2, in. |

Ast,10 Net Area of Steel Pipe, sq. in. |

Ac Concrete Area, sq. in. |

Structural Nominal Axial Compressive Resistance PNDC5,8,11, kips |

Structural Factored Axial Compressive Resistance1,8,11, kips |

| 14 | 13.5 | 0.25 | 0.22 | 9.43 | 424 | 255 | 382 | 0.156 | 6.70 | 143 | 788 | 473 |

| 13.25 | 0.375 | 0.33 | 14.00 | 630 | 378 | 567 | 0.266 | 11.28 | 138 | 976 | 586 | |

| 13 | 0.5 | 0.44 | 18.47 | 831 | 499 | 748 | 0.375 | 15.76 | 133 | 1160 | 696 | |

| 12.75 | 0.62512 | 0.55 | 22.84 | 1028 | 617 | 925 | 0.484 | 20.14 | 128 | 1340 | 804 | |

| 16 | 15.5 | 0.25 | 0.22 | 10.80 | 486 | 292 | 437 | 0.156 | 7.69 | 189 | 987 | 592 |

| 15.2 | 0.375 | 0.33 | 16.06 | 723 | 434 | 650 | 0.266 | 12.95 | 183 | 1204 | 722 | |

| 15 | 0.5 | 0.44 | 21.22 | 955 | 573 | 859 | 0.375 | 18.11 | 177 | 1416 | 850 | |

| 14.75 | 0.62512 | 0.55 | 26.28 | 1183 | 710 | 1064 | 0.484 | 23.18 | 171 | 1624 | 975 | |

| 20 | 19.5 | 0.25 | 0.22 | 13.55 | 610 | 366 | 549 | 0.156 | 9.65 | 299 | 1450 | 870 |

| 19.25 | 0.375 | 0.33 | 20.18 | 908 | 545 | 817 | 0.266 | 16.29 | 291 | 1722 | 1033 | |

| 19 | 0.5 | 0.44 | 26.72 | 1202 | 721 | 1082 | 0.375 | 22.83 | 284 | 1991 | 1195 | |

| 18.75 | 0.625 | 0.55 | 33.15 | 1492 | 895 | 1343 | 0.484 | 29.27 | 276 | 2256 | 1354 | |

| 24 | 23.25 | 0.375 | 0.33 | 24.31 | 1094 | 656 | 984 | 0.266 | 19.62 | 425 | 2327 | 1396 |

| 23 | 0.5 | 0.44 | 32.21 | 1450 | 870 | 1305 | 0.375 | 27.54 | 415 | 2652 | 1591 | |

| 22.75 | 0.625 | 0.55 | 40.03 | 1801 | 1081 | 1621 | 0.484 | 35.36 | 406 | 2973 | 1784 | |

| 22.5 | 0.75 | 0.66 | 47.74 | 2148 | 1289 | 1933 | 0.594 | 43.08 | 398 | 3290 | 1974 | |

| 1 Values are applicable for Strength Limit States. Modify value for other Limit States.

| ||||||||||||

751.36.5.8 Additional Provisions for Pile Cap Footings

Pile Group Layout:

Preliminary Number of Piles Required =

Layout a pile group that will satisfy the preliminary number of piles required. Calculate the maximum and minimum factored load applied to the outside corner piles assuming the pile cap/footing is perfectly rigid. The general equation is as follows:

Max. Load =

Min. Load =

The maximum factored load per pile must be less than or equal to PFDC for the pile type and size chosen. If not, the pile size must be increased or additional piles must be added to the pile group. Reanalyze until the pile type, size and layout are satisfactory.

The minimum factored load per pile should preferably be greater than zero. If this cannot be practically satisfied, the factored pullout resistance of the pile shall be calculated.

Resistance of Pile Groups in Compression LRFD 10.7.3.9

If the cap is not in firm contact with the ground and if the soil at the surface is soft, the individual nominal resistance of each pile (751.36.5.5) shall be multiplied by an efficiency factor, , based on pile spacing.

751.36.5.9 Estimate Pile Length and Check Pile Capacity

751.36.5.9.1 Estimated Pile Length

Friction Piles:

Estimate the pile length required to achieve the minimum nominal axial compressive resistance, Rndr, for establishment of contract pile quantities. Perform a static analysis to determine the nominal resistance profile of the soil. For each soil layer the appropriate resistance factor, ϕstat, shall be applied to account for the reliability of the static analysis method chosen in order to create a factored resistance profile. The penetration depth would then occur at the location where the factored resistance profile intercepts the factored load. Similarly, for a uniform soil layer the adjusted nominal resistance, Rnstat, can be determined from the equation below.

ϕdyn x Rndr = ϕstat x Rnstat ≥ Factored Load LRFD C10.7.3.3-1

Where:

- ϕdyn = see EPG.751.36.5.3

- Rndr = Minimum nominal axial compressive resistance = Required nominal driving resistance

- ϕstat = Static analysis resistance factor per LRFD Table 10.5.5.2.3-1 or as provided by the Geotechnical Engineer. Factors for side friction and end bearing may be different.

- Rnstat = Adjusted Nominal resistance due to static analysis reliability

Use soil profiles from borings and mimic soil characteristics as closely as possible in computations or software to calculate the geotechnical resistance and for estimating the length of pile.

It is not advisable to design pile deeper than available borings or to reach capacity within the bottom 3 to 5 feet of borings. If a longer pile depth is needed to meet design requirements then request Geotechnical Section to provide deeper borings or increase the number of piles which will reduce load per pile as well as the required pile length.

For friction pile the top five feet of soil friction resistance may be neglected with SPM or SLE approval for possible disturbance from MSE wall excavation prior to driving pile.

End Bearing Piles:

The estimated pile length is the distance along the pile from the cut-off elevation to the estimated tip elevation considering any penetration into rock. The estimated tip elevation shall not be shown on plans for end bearing piles.

The geotechnical material above the estimated end bearing tip elevation shall be reviewed to review the presence of glacial till or similar layers exist. If these layers are present, then a static analysis shall be performed to verify if the required pile resistance is reached at a higher elevation due to pile friction capacity.

751.36.5.9.2 Check Pile Geotechnical Capacity (Axial Loads Only)

Use the same methodology outlined in EPG 751.36.5.9 Estimate Pile Length and Check Pile Capacity.

751.36.5.9.3 Check Pile Structural Capacity (Combined Axial and Bending)

Structural design checks which include lateral loading and bending shall be accomplished using the appropriate structural resistance factors.

751.36.5.10 Pile Nominal Axial Compressive Resistance (kips)

The minimum nominal axial compressive resistance, Rndr, must be calculated and shown on the final plans. The factored axial compressive resistance will be used to verify the pile group layout and loading. The minimum nominal axial compressive resistance will be used in construction field verification methods to obtain the required nominal driving resistance.

- Minimum Nominal Axial Compressive Resistance = Required Nominal Driving Resistance,

- = Maximum factored axial loads/ϕdyn

- ϕdyn = Resistance factor of the dynamic method to be used to estimate nominal pile resistance during pile installation. LRFD 10.5.5.2.3.1

The value of Rndr shown on the plans shall be the greater of the value required at the Strength limit state and Extreme Event limit state. This value shall not be greater than the structural nominal axial compressive resistance of the pile nor shall it exceed the maximum nominal driving resistance of the steel shell for CIP piles. See EPG 751.36.5.5. LRFD 10.7.7

751.36.5.11 Check Pile Drivability

Drivability of the pile through the soil profile can be investigated using “GRLWEAP” program or other available software. Designers may import soil resistances from a static analysis programor input soil values directly into GRLWEAP program to perform drivability.

If soil values are to be directly input into GRLWEAP program, enter in values of sand and clay layers with specific values of cohesion or internal friction angle or just by uncorrected blow count values obtained from borings.

Drivability analysis shall be performed for all piles (bearing pile and friction pile) using the Delmag D19-42 hammer and the Delmag D30-23 – Heavy Hammer.

Use soil profiles from borings and mimic soil characteristics as closely as possible for computations or in software to perform drivability analysis of any kind of pile.

Structural steel HP Pile:

Drivability analysis shall be performed for two cases:

- 1. Box shape

- 2. Perimeter

Drivability shall be performed considering existing condition without considering any excavation/ disturbance (i.e., possible disturbance to top 5 feet of soil from MSE wall excavation prior to driving pile), liquefaction or future scour loss.

Hammer types:

| Hammer used in the field per survey response (2017) | ||

|---|---|---|

| GRLWEAP ID | Hammer name | No. of Responses |

| 41 | Delmag D19-421 | 13 |

| 40 | Delmag D19-32 | 6 |

| 38 | Delmag D12-42 | 4 |

| 139 | ICE 32S | 4 |

| 15 | Delmag D30-32 | 2 |

| Delmag D25-32 | 2 | |

| 127 | ICE 30S | 1 |

| 150 | MKT DE-30B | 1 |

| 1 Delmag series of pile hammers is the most popular, with the D19-42 being the most widely used. | ||

Hammer usage in the field will be surveyed every five years. The above results will be revised according to the new survey and the most widely used hammer will be selected for drivability analysis.

The contractor is responsible for determining the hammer energy required to successfully drive the pile to the minimum tip elevation and to reach the minimum nominal axial compressive resistance specified on the plans. The contractor shall perform a drivability analysis to select an appropriate hammer size to ensure the pile can be driven without overstressing the pile and to prevent refusal of the pile prior to reaching the minimum tip elevation. The contractor shall plan pile driving activities and submit hammer energy requirements to the engineer for approval before driving.

Practical refusal is defined at 20 blows/inch or 240 blows per foot.

Driving should be terminated immediately once 30 blows/inch is encountered.

Nominal Driving Stress LRFD 10.7.8

- Nominal driving stress ≤ 0.9*ϕda*Fy

- For structural steel HP pile, Maximum nominal driving stress = 45 ksi

- For CIP pile, Maximum nominal driving resistance, see EPG 751.36.5.7.2 (unfilled pipe for axial analysis).

If analysis indicates the piles do not have sufficient structural or geotechnical strength or drivability issues exist then consider increasing the number of piles.

751.36.5.12 Information to be Included on the Plans

See EPG 751.50 A1 Design Specifications, Loadings & Unit Stresses for appropriate design stresses to be included in the general notes.

See EPG 751.50 E2 Foundation Data Table for appropriate data to be included in the foundation data table for HP pile and CIP pile and any additional notes required below the table. See Bridge Standard Drawings “Pile” for CIP data table.