751.22 Prestressed Concrete I Girders

| Video |

| Concrete Girder |

751.22.1 General

751.22.1.1 Material Properties

Concrete

Concrete strength utilized for prestressed girders may be conventional or high strength concrete (HSC) which shall be identified on the girder plans. HSC shall be concrete strengths in excess of 8.0 ksi and may only be used with the permission of the Structural Project Manager or Structural Liaison Engineer. Costs may increase due to production modifications necessary to obtain the required HSC strength.

Conventional concrete strength for P/S I-Girder shall be the following:

- For MoDOT Standard Girders:

- ,

- Optional higher concrete strength shall be:

- ,

- OR

- With the approval of the Structural Project Manager or Liaison:

- ,

- For NU Standard Girder:

- ,

- Modulus of Elasticity,

- Where,

- f'c in ksi

- K1 = correction factor for source of aggregate

- = 1.0 unless determined by physical testing

- K1 = correction factor for source of aggregate

| Prestressing strand | ||

|---|---|---|

| Type of strand: | ||

| AASHTO M203 (ASTM A416) Grade 270 | ||

| Uncoated, seven-wire, low-relaxation strand | ||

| Ultimate tensile strength, | ||

| Yield strength, | ||

| Strand modulus of elasticity, | ||

| For conventional concrete strengths: | ||

| Strand diameter, | ||

| Strand area, | ||

| OR: | ||

| Strand diameter, | ||

| Strand area, | ||

| Order of Material Use for Increasing Girder Capacity in Order of Increasing Costs | ||

| 1. Increase concrete strength (readily producible by fabricator) | ||

| 2. Increase strand size (readily available from fabricator but steel costs are high) | ||

| 3. Modify MoDOT shape (most costly and inconvenient becasue of forming bed modifications required) (except NU shape) | ||

| Mild reinforcing steel | ||

| Minimum yield strength, | ||

| Steel modulus of elasticity, | ||

| Welded Wire Reinforcement | ||

| Minimum yield strength, | ||

| Steel modulus of elasticity, | ||

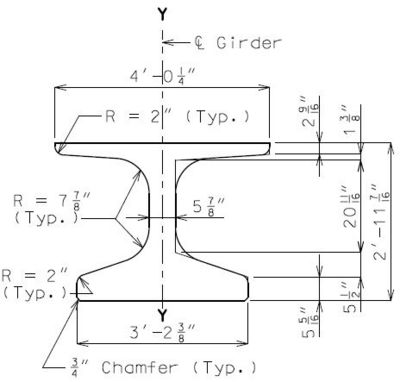

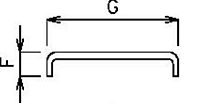

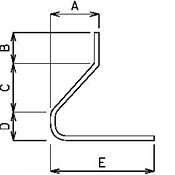

751.22.1.2 Geometric Dimensions

The ratio of the depth of girder to span length will in general be not less than 1/18.

The cross sectional dimensions of the girder shall be one of the following:

- MoDOT Standard Girders:

| BEAM TYPE 2 | BEAM TYPE 3 | BEAM TYPE 4 | BEAM TYPE 6 |

| BEAM TYPE 7 | BEAM TYPE 8 |

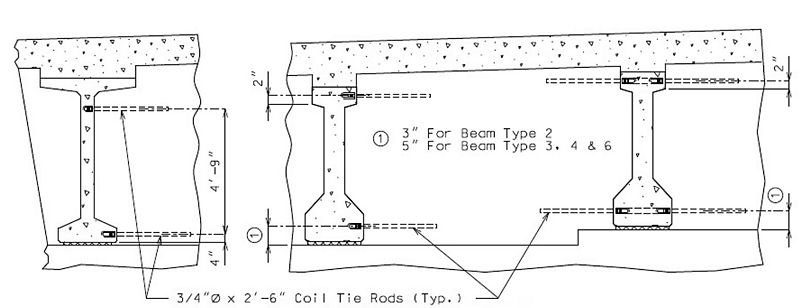

If the web is required to be increased, then the top and bottom flanges are to be increased by the same amount. (1" increments 2" max.).

- NU Standard Girders:

751.22.1.3 Typical Span Ranges

The following charts provide span ranges (limits) for P/S I-girders based on girder spacing and standard roadway widths.

Limitations of the Charts:

- A. Standard Concrete Charts Only

- Criteria used in determining maximum span lengths for lower conventional concrete strength:

- 1) Low-relaxation strand with 0.5” strand diameter

- 2) Concrete strengths, = 4.5 ksi and = 6.0 ksi

- 3) 3-span bridge consisting of 3 equal length girders made continuous and composite

- B. Optional Concrete Charts Only

- Criteria used in determining maximum span lengths for greater conventional concrete strength:

- 1) Low-relaxation strand with 0.6” strand diameter

- 2) Concrete strengths, = 5.0 ksi and = 7.0 ksi

- 3) 3-span bridge consisting of 3 equal length girders made continuous and composite

- C. Both Standard Concrete and Optional Concrete Charts

- Criteria used in determining span ranges for both Standard and Optional Concrete conventional strengths.

- 1) Minimum span lengths were determined by the positive moment capacity of the smallest strand arrangement per beam shape. Shorter span lengths are possible.

- 2) Based on 10 ft. design lanes. (Current design practice meets AASHTO LRFD and uses 12 ft. design lanes.)

- 3) Based on unrefined prestress loss equations. (Current design practice meets AASHTO LRFD and uses refined losses.)

Recommended Adjustments for Using the Charts:

Because the span limit charts were developed using older design criteria as noted above, increased span lengths are probable.

- 1) Span limits given in all charts should be increased 10 percent to account for current design practice. Ten percent can safely be used without a preliminary girder analysis.

- 2) Span limits given in all charts shall be increased when a preliminary girder analysis based on actual design conditions is performed which shall be noted on the Design Layout.

| Span range charts are planned for future replacement. Use the recommended adjustments until implemented. |

Given Roadway Widths and Girder Spacing

Given Roadway Widths and Girder Spacing

751.22.1.4 Span and Structure Lengths

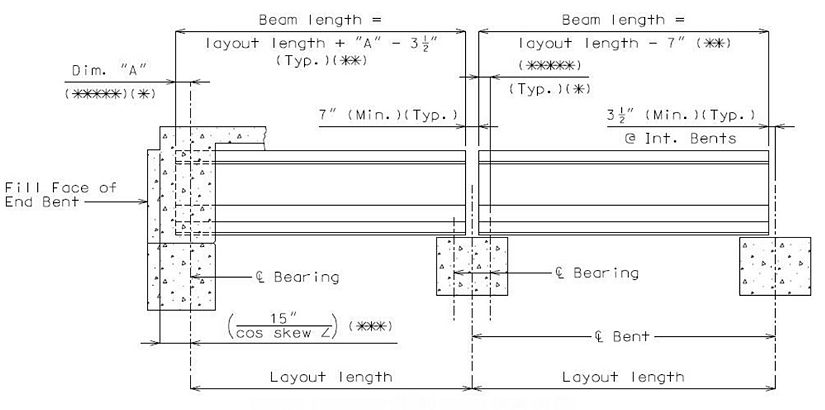

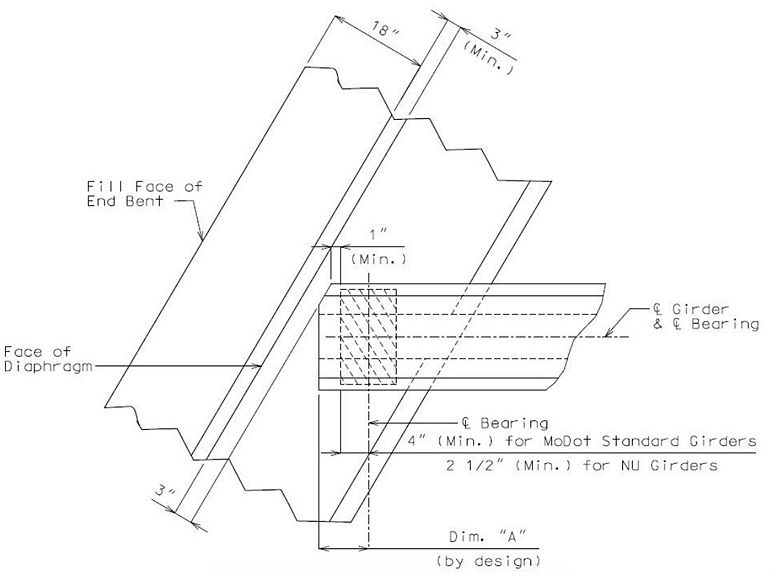

Girder Length and Geometric Layout

- Tangent Bridges

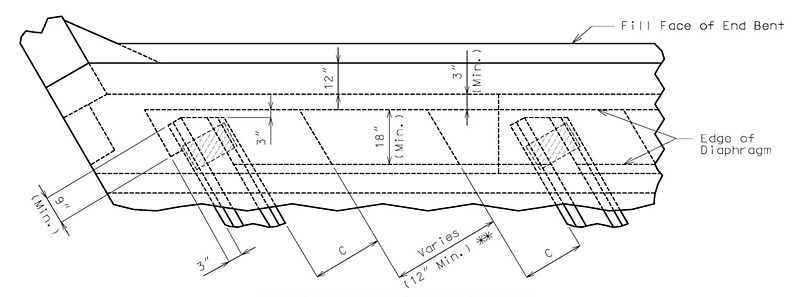

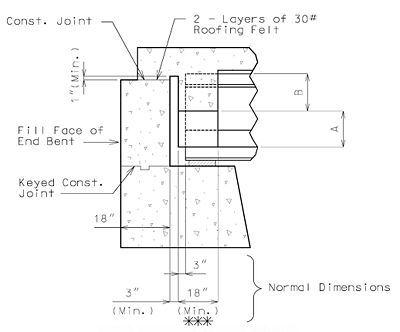

- Girder lengths of exterior spans (i.e., end spans) shall be computed using the requirements shown below.

- Girder lengths of interior spans shall be computed using the requirements shown below.

- Curved Bridges

- Layout of any curved structure may be done using any coordinate geometry programs available. To layout the bridge, use the following steps:

- Start out by laying in the centerline (CL) of the survey curve.

- Locate the tie point of the bridge. This point will usually be on the CL of the survey curve but may be on a baseline which is offset a certain distance to the CL of the survey curve.

- A second tie point may be required if the skew is not measured to the CL of roadway at the bridge tie point. If this is the case, establish the tie point at the specified station and plot the skew line at the required angle.

- Next, on the centerline of structure or baseline curve, locate the station of the CL of bent for each intermediate bent and the fill face for the end bents. Once these points are located, plot lines through these stations parallel to skew line. Normally the layout file will specify that all bents are parallel to the skew line; however, there may be times when the bents are radial or have varying skews.

- When locating the stations in the preceding step, the distance between CL of intermediate bents are exactly the layout lengths specified on the file. However, the end spans need to follow the procedure for calculating length set forth in this section.

- When the CL of the intermediate bents and the fill face lines have been added, chords should be drawn connecting these points sequentially. For example, if you have a three span bridge, chords should be drawn from the fill face of bent 1 to CL of bent 2, CL bent 2 to CL bent 3, and CL bent 3 to fill face bent 4.

- When all the chords are in, offset each girder in each span parallel to this chord. The perpendicular distance between girders will be the same for all spans, but the skew distance between girders along the bent will vary from bent to bent depending on the skew to the CL at that point. The designer needs to be aware of the fact that at an intermediate bent the distance between bearings on the approaching and leaving span sides will be different distances. These bearings will not line up across the bent and will actually diverge more the farther away they are from the CL of the survey.

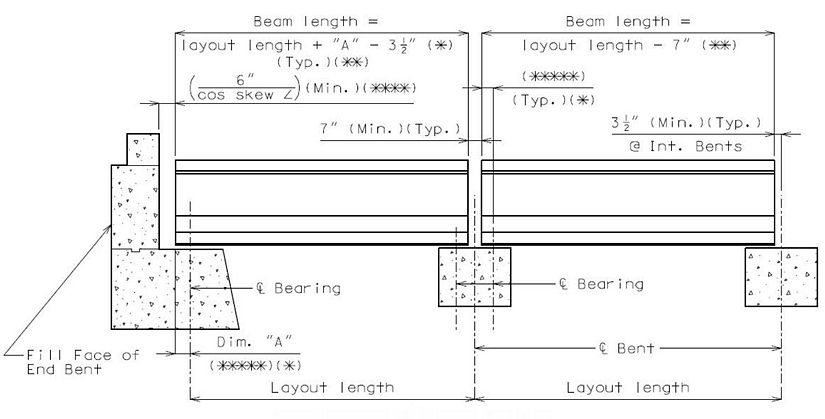

- When establishing the CL of bearing points, the designer needs to allow for a minimum of seven (7) inches between ends of girders at the bents while keeping in mind that the girders will be offset and at different skews. If the offset is greater than half the girder bottom flange width, see Structural Project Manager. The distance from the end of girder to CL of bearing point should be half of the bearing length plus one inch minimum clearance. Once the distance for CL bent to CL of bearing is calculated, the designer should offset lines by that dimension on either side of the CL of bent. These lines will then be intersected with each of the girder lines to create the bearing points on each bent.

- Between the bearing points at the ends of the girders, quarter points or tenth points need to be established, depending on the girder span. These points will be used in calculating the haunch and bottom of slab elevations for the bridge deck.

- The bridge deck and barrier curbs can be laid in by offsetting the CL of roadway to each side by the proper distance. Curves should be laid in to designate both the inside and outside edges of the barrier curb. These will later be useful in laying in the wings and end bents.

- After the outside edge of slab curves are plotted, the curve offsets need to be found. The intersection point of the outside edge of slab and the CL of each bent or fill face can be connected with chords. The distance between these chords and their partner curves need to be calculated at five foot intervals beginning at the center point of each chord.

- Joints are placed in the barrier curb at each bent. These joints are placed perpendicular to the CL of the roadway through the intersection point of the CL bent and the inside of barrier curb.

- Wing layout length is given on the profile sheets in the layout file. An arc should be struck so as to intersect the inside of barrier curb the specified length from a point at the intersection of the fill face and the inside of barrier curb. This point will mark the end of the wing which is perpendicular to the CL of the roadway.

- The vertical curve information needs to be added so a program can calculate the elevations at the desired stations. After this is done, the designer can request any of the following information which will be needed:

- Stations and elevations of all points

- Offset distances to the chords

- Lengths of girders

- Distances between bearings

- Angles between girders and each bent

- Lengths of bents

- Lengths of barrier curbs between joints

- Minimum vertical clearance

- Note: Layout length for single span shall be measured from centerline of bearing to centerline of bearing. If the difference between layout length of the end span and interior span is within 1 ft., then layout length should be adjusted if possible so the girder lengths are equal for end span and interior span.

- (*) Minimum dimension from edge of bearing pad to end of girder equals one inch.

- (**) Design layout lengths are horizontal lengths. Girder lengths should be adjusted according to grade and shall be specified to the nearest 1/8 inch.

- (***) For large skews, end bent beam caps may need to be larger to provide edge distance.

- (****) Horizontal distance along certerline of girder.

- (*****) = 1” (minimum) + ½ bearing pad length which equals:

- 5” (minimum) for MoDOT Standard Girders and Adjacent P/S Box Beams,

- 3 ½” (minimum) for NU Girders and P/S Spread Box Beams.

- (*****) = 1” (minimum) + ½ bearing pad length which equals:

Note: Non-Integral end bents with skews greater than 40° shall always have girder ends coped. Skews less than 40° shall have girder ends coped on case by case basis. It is preferable to not cope across the web.

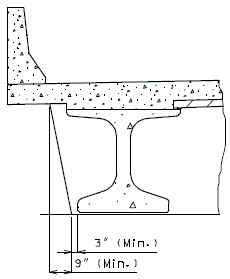

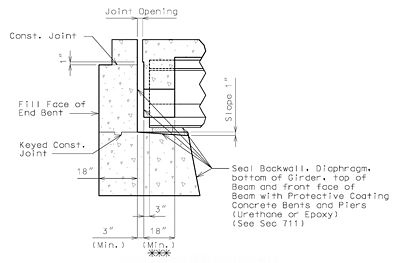

Check clearance from fill face of integral end bents to bottom flanges of NU standard girders. Maintain 3” (min.) clearance. Coping may be permitted with approval of the Structural Project Manager or Structural Liaison Engineer.

(INTEGRAL END BENTS)

(NON-INTEGRAL END BENTS)

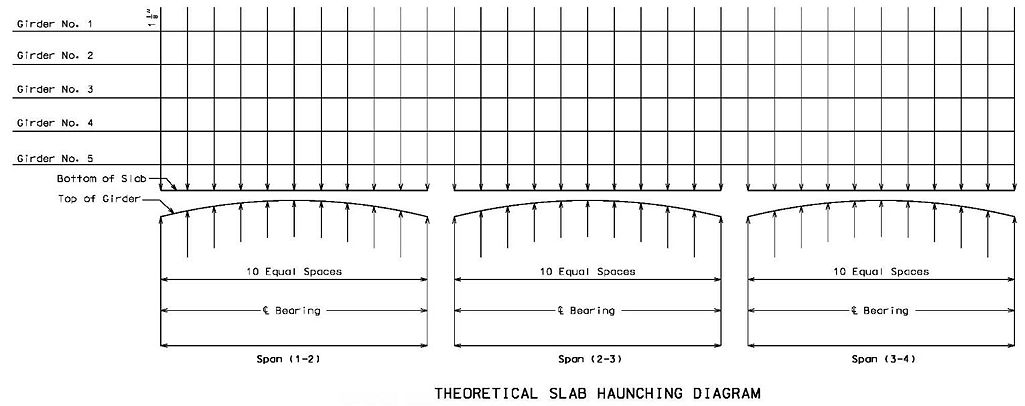

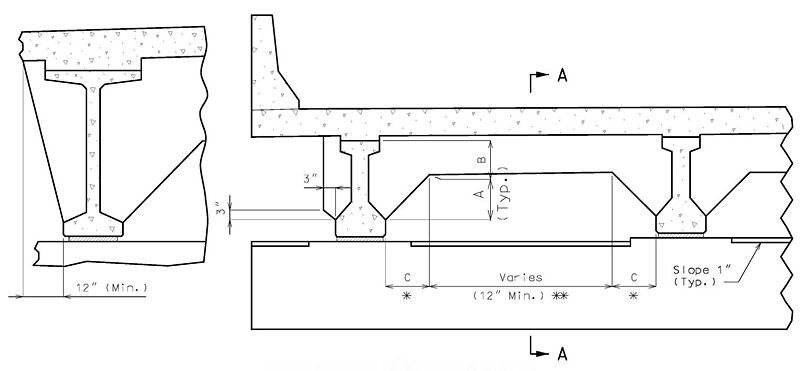

751.22.1.5 Constant and Varied Joint Filler Loads

Varied joint filler load

The prestressed I-girder should first be designed assuming that the contractor will vary the joint filler supporting the panels on the girder flange. This assumption will maintain the minimum slab/panel combination thickness of 8 1/2”, and will eliminate the possibility of increased load due to varying slab thickness.

Constant joint filler load

With the girder designed and the camber and haunching dimensions calculated, the girder should be checked assuming the contractor will use a constant 1” joint filler. This will cause the slab thickness to vary due to camber of the girder, increasing load. This additional load shall be placed as a concentrated load at 1/8 point from each end of the girder.

An example of how this concentrated load could be calculated is shown as follows:

- Load

- Determine the concentrated load* to girders by distributing w transversely across the girders. If the minimum haunch is greater than 1” joint filler, the additional haunch shall be included in the slab thickness as a uniform load. If the use of these loads causes the girder design to change, it shall be the responsibility of the designer to determine if the camber and haunching should be recalculated.

This load shall be positioned at the 1/8 point from centerline of bearing pad.

The girder and bearing designs should be checked for the constant joint filler option and constant joint filler load. However, camber, haunching and beam seat elevations shown on the plans should be based on the variable joint filler option.

751.22.2 Design

751.22.2.1 Load Combinations

In general, each component shall satisfy the following equation:

Where:

| = Total factored force effect | |

| = Force effect | |

| = Load modifier | |

| = Load factor | |

| = Resistance factor | |

| = Nominal resistance | |

| = Factored resistance |

- Limit States

The following limit states shall be considered for P/S Girder design:

- SERVICE I - for compressive stress

- SERVICE III - for tensile stress

- STRENGTH I

See LRFD Table 3.4.1-1 for Loads and Load Factors applied at each given limit state.

- Resistance factors,

STRENGTH limit states, see LRFD Article 6.5.4.2 & 5.5.4.2.1

For all other limit states, = 1.00

See EPG 751.2.3.1 Load Modifiers.

751.22.2.2 Prestressing Strands

Transfer Length of Prestressing Strands

The prestressing force may be assumed to vary linearly from zero at the point where bonding commences to a maximum at the transfer length. The transfer length may be taken as 60 times the strand diameter.

Development Length of Prestressing Strands

The development length for prestressing strands shall be taken as:

Where: = Nominal diameter of strand, (in.) = Average stress in prestressing strand at the time for which the nominal resistance of the girder is required, (ksi)

Stress limits for prestressing strands

Strand stress at service limit state shall not exceed the following:

At jacking:

- ksi

- (For typical girders and fabrication economy, )

At service limit state after all losses:

- ksi

Where:

| = Stress in prestressing strand at jacking, (ksi) | |

| = Effective stress of strand after all losses, (ksi) | |

| = Yield strength of strand, (ksi) | |

| = Ultimate tensile strength of strand, (ksi) |

Prestress Losses

Refined estimates of time-dependent losses are used, based on AASHTO LRFD Article 5.9.5.4, as opposed to approximate lump sum estimate of losses in AASHTO LRFD Article 5.9.5.3.

The prestress losses shall be calculated to investigate concrete stresses at two different stages.

- Temporary stresses immediately after transfer:

- Final stresses

SERVICE I and SERVICE III Limit states shall be investigated at each stage.

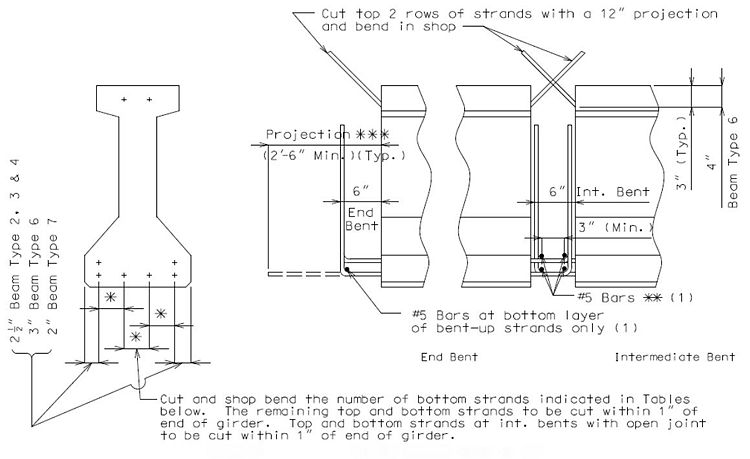

Harped Strands

Harped strands, although they add to the shear strength of the girder, are primarily used to keep the girder stresses (both top and bottom) within allowable limits while developing the full capacity of the girder at midspan.

Harped strands should be held down at points of 0.4 of the distance from each end of the girder.

The jacking force applied to prestress strands produces an excessive vertical uplift in short spans on tall girders resulting in failure of harped strand hold-downs. The allowable limits for hold-downs are as follows:

- 5 kip/strand

- 10 kip/bolt

- 42 kip/hold-down

If necessary lower harped strand end location to meet criteria or use straight strands only. Investigate the possibility of using all straight strands when strength check of a hold-down device exceeds allowable.

Straight Strands.

Short spans (<40 ft.) are to use straight strands only for all girders greater than 2'-8" tall. Use at least two straight strands at the top of the girder when straight strands are used. Where straight strands only will not work a single hold-down point may be used. Note: A single point hold-down has twice the uplift force.

Strand Arrangement Optimizing

Using all straight strands for girder lengths less than 70 ft. should be investigated for MoDOT Standard Girder Types 6, 7, 8 and all NU Standard Girders in order to reduce risk of strand or hold-down breakage, increase safety by reducing risk of injury during fabrication and reduce cost.

Consider using the same section for all spans. This permits the use of shorter girders in the casting bed with longer girders, even if straight strands are needed, in the top flanges of the girders. They can be placed at either end of the bed and still optimize the usage of the bed.

Consider using the same number of draped strands for all spans and debond where needed. Strand patterns should be similar between long and short spans. For example, the designer should not use a single column of draped strands on the short spans and two columns of draped strands on the long spans. This will prevent optimization of the bed.

Debonding Strands

In all debonding operations the prestressing forces must be in such a manner as to prevent any sudden or shock loading.

Debonding a strand consists of wrapping the unnecessary strand(s) with a polyethylene plastic sleeve that prevents interaction of the strand with the concrete during casting and release which prevents any prestress force transfer.

751.22.2.3 Flexure

Flexure capacity of prestressed I-girders shall be determined as the following.

Flexural resistance at strength limit state

Where:

| = | Flexural resistance | |

| = | Nominal flexural resistance | |

| = | Total factored moment from Strength I load combination | |

| = | Flexural resistance factor as calculated in LRFD 5.5.4.2 |

Negative moment reinforcement design

P/S I-girder shall be designed as a reinforced concrete section at regions of negative flexures (i.e., negative moments).

At least one-third of the total tensile reinforcement provided for negative moment at the support shall have an embedment length beyond the point of inflection not less than the specified development length of the bars used.

Slab longitudinal reinforcement that contributes to making the precast beam continuous over an intermediate bent shall be anchored in regions of the slab that can be shown to be crack-free at strength limit states. This reinforcement anchorage shall be staggered. Regular longitudinal slab reinforcement may be utilized as part of the total longitudinal reinforcement required.

Effective Slab Thickness

An effective slab thickness shall be used for design by deducting from the actual slab thickness a 1” integral, sacrificial wearing surface.

Design A1 reinforcement in the top flange

The A1 reinforcement shall resist the tensile force in a cracked section computed on the basis of an uncracked section. For MoDOT girders, A1 reinforcement shall consist of deformed bars. For NU girders, A1 reinforcement shall consist of strands for reinforcement support (4 – 3/8” Strands, Typ.) and WWR (6 – W8, Typ.) with deformed bars added only as needed. Reinforcement shall be designed and spliced using f’ci in accordance with EPG 751.5.9.2.7 Development and Lap Splices.

Required steel area is equal to:

Where:

| = , allowable tensile stress of mild steel, (ksi) | |

| = Resultant of total tensile force computed on the basis of an uncracked section, (kips) |

Limits for reinforcement

The following criteria shall be considered only at composite stage.

Minimum amount of prestressed and non-prestressed tensile reinforcement shall be such that the factored flexural resistance, Mr, is at least equal to the lesser of:

- 1) Mcr LRFD Eq. 5.7.3.3.2-1

- 2) 1.33Mu

Where:

| Mcr | = | Cracking moment, (kip-in.) |

| Mu | = | Total factored moment from Strength I load combination, (kip-in.) |

751.22.2.4 Shear

Shear capacity of P/S I-girder should be checked along girder length and girder-slab interface.

Shear resistance at strength limit state

Where:

| = | Shear resistance | |

| = | Nominal shear resistance | |

| = | Total factored shear from Strength I load combination | |

| = | Shear resistance factor |

Nominal shear resistance

The nominal shear resistance, , shall be lesser of:

- , or

Where:

Where:

| = | Nominal concrete shear resistance, (kips) | |

| = | Nominal shear reinforcement resistance, (kips) | |

| = | Component of prestressing force in the direction of shear force, (kips) | |

| = | Thickness of web, (in.) | |

| = | Effective shear depth taken as the distance measured perpendicular to the neutral axis, between the resultants of tensile and compressive forces due to flexure, (in.) | |

| = | Spacing of shear reinforcement, (in.) | |

| = | Factor indicating ability of diagonally cracked concrete to transmit tension | |

| = | Angle of inclination of diagonal compressive stress, (degree) | |

| = | 90.0, Angle of inclination of shear reinforcement to a longitudinal axis, (degree) | |

| = | Area of shear reinforcement, (in.2) | |

| = | Minimum yield strength of tension shear reinforcement, (ksi) |

Design sections near supports

Where a reaction force in the direction of the applied shear introduces compression into the end region of girder, the location of the critical section for shear is measured from the internal face of support a distance, dv. Otherwise, the design section shall be taken at the internal face of the support.

Where:

= effective shear depth taken as the distance, measured perpendicular to the neutral axis, between the resultants of the tensile and compressive forces due to flexure; it need not be taken to be less than the greater of 0.9de and 0.72h.

Girder regions requiring shear reinforcement

Girder shear reinforcement, usually consisting of stirrups, shall be provided where:

Where:

| = | Factored shear force from Strength I load combination, (kips) | |

| = | Nominal concrete shear resistance, (kips) | |

| = | Component of prestressing force in the direction of shear force, (kips) | |

| = = |

Shear resistance factor

0.9 for normal weight concrete |

Shear Reinforcement Limits

Minimum reinforcement

Area of shear reinforcement shall not be less than:

Where:

| = | Area of shear reinforcement, (in.2) | |

| = | Thickness of web, (in.) | |

| = | Spacing of shear reinforcement, (in.) | |

| = | Final concrete compressive strength, (ksi) |

Maximum reinforcement

Maximum spacing of shear reinforcement shall be determined as:

If , then

If , then

Where:

| = | Effective shear depth taken as the distance measured perpendicular to the neutral axis, between the resultants of tensile and compressive forces due to flexure, (in.) | |

| = | Shear stress on concrete, (ksi) | |

| = | Maximum spacing of shear reinforcement, (in.) |

Shear stress on concrete shall be determined as:

Where:

| = | Shear stress on concrete, (ksi) | |

| = | Factored shear from Strength I load combination, (kips) | |

| = = |

Shear resistance factor

0.9 for normal weight concrete | |

| = | Thickness of web, (in.) | |

| = | Component of prestressing force in the direction of shear force, (kips) | |

| = | Effective shear depth taken as the distance measured perpendicular to the neutral axis, between the resultants of tensile and compressive forces due to flexure, (in.) | |

| = | ||

| = | Distance from extreme compression fiber to the centroid of tensile force in the tensile reinforcement, (in.) | |

| = | Total height of girder including slab thickness, (in.) |

Girder-Slab Interface

The horizontal shear between the girder and slab shall be determined as specified in LRFD 5.8.4.3. The nominal horizontal shear resistance of the interface plane shall be taken as specified in LRFD 5.8.4.1. Minimum interface shear reinforcement shall be provided as specified in LRFD 5.8.4.4. The parameters used in determining the nominal horizontal shear resistance shall be taken as specified for a “cast-in-place concrete slab on clean concrete girder surfaces, free of laitance with surface roughened to an amplitude of 0.25 inch.”

The interface shear shall be resisted by extending and anchoring the vertical shear reinforcement into the slab. If the resistance provided by extending the vertical shear reinforcement is inadequate then additional U-bars may be provided as shown for a MoDOT Standard Girder Type 7 in EPG 751.22.3.6 Girder Reinforcement.

For NU Girders the edges of the top of girder flange are intentionally debonded (see figure below) and shall not be included when determining the nominal horizontal shear resistance. See EPG 751.50 Standard Detailing Notes H2c2.10 for specifics about the debonded width for NU Girders. Similarly, for all other prestressed girders, the joint filler width supporting precast panels shall be considered debonded and excluded when determining the interface resistance.

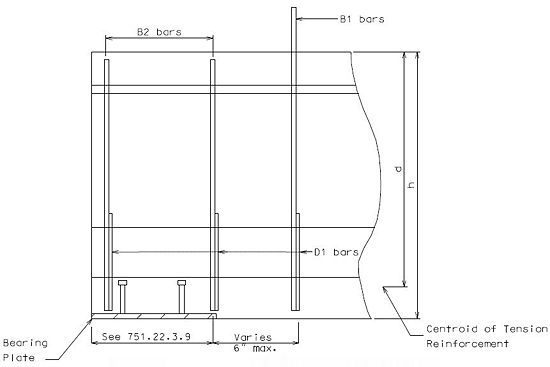

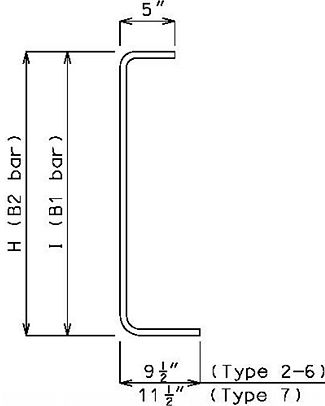

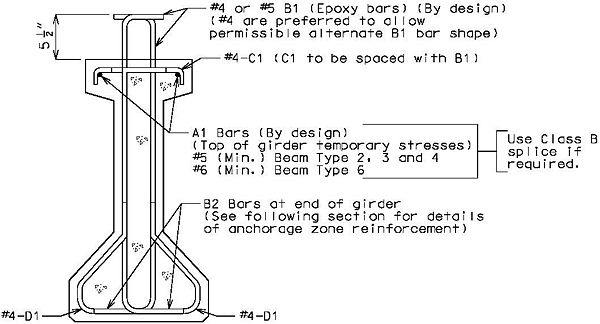

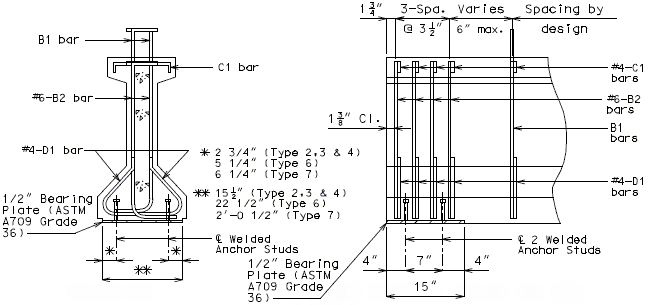

Pretensioned anchorage zones

The bursting resistance of anchorage zones provided by vertical reinforcement (i.e., B2 bars, WWF, G402 bars) in the ends of prestressed girders at the service limit state shall be taken as:

Where:

| = | Stress in mild steel not exceeding 20 ksi | |

| = | Total area of vertical reinforcement located within a minimum distance of h/4 from the end of the girder where h is overall depth of precast member as shown below. | |

| = | Prestressing force at transfer |

Confinement reinforcement

Reinforcement (i.e., D1 bars or G301 bars, not shown) shown in the figure above shall be placed to confine the prestressing strands in the bottom flange for a minimum distance of 1.5d from the end of beam.

The reinforcement shall not be less than #3 deformed bar, with spacing not exceeding 6.0 inches and shaped to enclose the strands.

MoDOT extends the use of D1 and G301 bars for the full length of girders.

751.22.2.5 Deformations

Criteria for deflection

For investigating maximum absolute deflection, all design lanes shall be loaded, and all supporting components should be assumed to deflect equally.

For composite design, the design cross-section should include the entire width of the roadway and the structurally continuous portions of railings, sidewalks, and median barriers. Note that safety barrier curbs are usually discontinuous over the bents. For skewed bridges, a right cross-section may be used.

Service I load combination shall be used. Dynamic load allowance shall be applied.

See EPG 751.2.4.2 Live Load Deflection Limits.

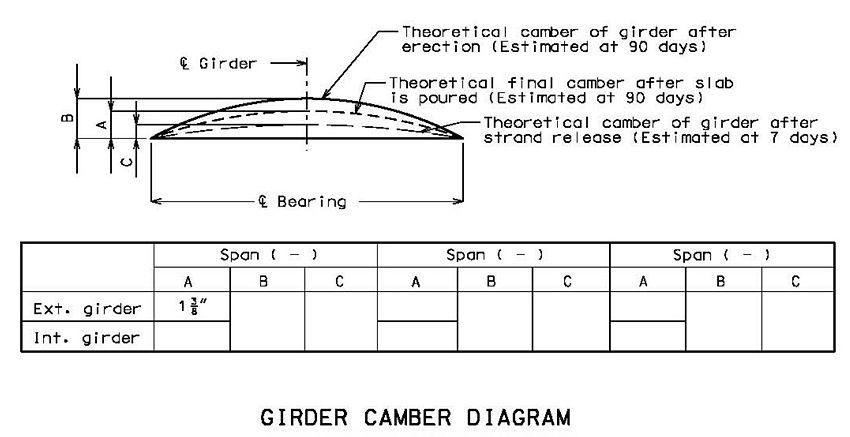

Calculation of deflection and camber

Deflection and camber calculations shall consider all internal loads (i.e., prestressing, concrete creep, and shrinkage) and external loads such as dead loads and live loads.

Camber is an upward displacement caused by moment due to prestressing forces. Deflection is a downward displacement due to external loads. Therefore, both camber and deflection shall be considered in making an appropriate adjustment for final profile grade on the bridge.

Initial camber at transfer at midspan

Total initial camber at transfer due to self-weight of girder and prestressing forces shall be determined as:

Where:

| = Initial camber at transfer | |

| = Deflection due to self-weight of girder | |

| = Camber due to prestressing straight strands | |

| = Camber due to prestressing harped strands |

Note: Positive and negative values indicate downward and upward displacements, respectively.

Camber at midspan after strand release (Estimated at 7 days)

Theoretical camber of girder after strand release due to self-weight of girder and prestressing forces shall be determined at 7 days as:

Where:

| = Camber at 7 days after strand release with creep | |

| = Time - dependent camber due to creep at 7 days |

Note: Camber is calculated 7 days after strand release to allow sufficient time for inspection. See EPG 1029 Fabricating Prestressed Concrete Members for Bridges.

Camber at midspan after erection (Estimated at 90 days)

Theoretical camber of girder after erection due to self-weight of girder and prestressing forces shall be determined at 90 days as:

Where:

| = Camber at 90 days after strand release with creep | |

| = Time - dependent camber due to creep at 90 days |

Final camber at midspan after slab is poured

Total deformation after slab is poured can be determined as the sum of theoretical camber of girder after erection (90 days) and deflections due to slab and concentrated loads (haunch, diaphragms, etc.) before composite action between slab and girder.

Where:

| = | Final camber after slab is poured | |

| = | Deflection due to weight of slab | |

| = | Deflection due to concentrated loads (haunch, diaphragms, etc.) |

Final camber along span length

Deformations along the span length can be approximately determined as a product of final camber at midspan times correction factors.

| = | 0.3140 at span fraction of 0.10 | |

| = | 0.5930 at span fraction of 0.20 | |

| = | 0.7125 at span fraction of 0.25 | |

| = | 0.8130 at span fraction of 0.30 | |

| = | 0.9520 at span fraction of 0.40 | |

| = | 1.0000 at span fraction of 0.50 |

Calculation of camber (upward)

Camber at midspan due to strand forces is determined as the following: For straight strands,

Where:

Where:

| = Total prestressing force of straight strands at transfer (including losses due to elastic shortening), (kips) | |

| = Total prestressing force in straight strands due to time-dependent losses prior to slab placement (kips). Opposite in sign to , typically. | |

| = Distance between centerlines of bearing pads, (in.) | |

| = Initial concrete modulus of elasticity based on , (ksi) | |

| = Final concrete modulus of elasticity based on (ksi) | |

| = Moment of inertia of transformed non-composite section computed based on , (in.4) | |

| = Moment of inertia of transformed non-composite section based on , (in.4) | |

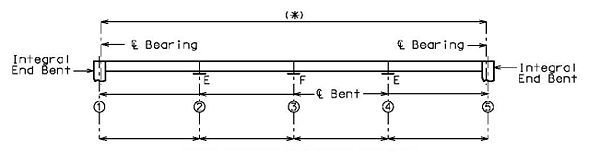

| = Eccentricity between centroid of straight strands (CSS) and center of gravity of transformed non-composite section (CGB) as shown in Figure below, (in.) |

For two-point harped strands,

Where:

Where:

| = Total prestressing force of harped strands at transfer (including loss due to elastic shortening), (kips) | |

| = Total prestressing force of harped strands due to time-dependent losses prior to slab placement (kips) | |

| = Length between harped points, (in.) | |

| = Eccentricity between centroid of harped strands (CHS) and center of gravity of transformed non-composite section (CGB) at midspan as shown in Figure below, (in.) | |

| = Eccentricity between centroid of harped strands (CHS) and center of gravity of transformed non-composite section (CGB) at the end of girder as shown in Figure below, (in.) |

Calculations of deflections (downward)

Deflections at midspan due to dead loads are determined as the following: For self-weight of girder,

Where:

| = | Uniform load due to self-weight of girder, (kip/in.) |

For self-weight of slab,

Where:

| = | Uniform load due to self-weight of slab, (kip/in.) |

Weight of additional slab haunch may be treated as uniform or concentrated load as appropriate. Diaphragm weight should be treated as concentrated load.

For one concentrated load at midspan,

For two equal concentrated loads,

Where:

| = Concentrated load due to diaphragm and/or additional slab haunch, (kips) | |

| = Distance from the centerline of bearing pad to the applied load, P, (in.) |

Creep coefficient

Research has indicated that high strength concrete (HSC) undergoes less ultimate creep and shrinkage than conventional concrete.

Creep is a time-dependent phenomenon in which deformation increases under a constant stress. Creep coefficient is a ratio of creep strain over elastic strain, and it can be estimated as follows:

| = | |

| = | |

| = | |

| = | |

| = |

Where:

| = Creep coefficient. | |

| = 70, Average annual ambient relative humidity | |

| = Maturity of concrete, (days) Use 7 days for camber design after strand release Use 90 days for camber design after erection | |

| = Age of concrete when a load is initially applied, (days) Use 0.75 days for camber design. | |

| = Volume-to-surface area ratio, (in.) | |

| = Initial girder concrete compressive strength, (ksi) |

Where:

| = Moment due to girder weight at mid span. |

751.22.3 Details

751.22.3.1 Reinforcement Criteria

Minimum Concrete Cover

- 2.0" (Min.) to centerline of strands

- 1.0" for stirrups

Minimum Radius of Bar Bend in Stirrups

- 3 through #5 bars = 4.0 x Bar Diameter.

Minimum Spacing of Reinforcement Bars

For precast concrete, the clear distance between parallel bars in a layer shall not be lesser than:

- Nominal Diameter of bar

- 1.33 x Maximum Aggregate Size

- 1.0"

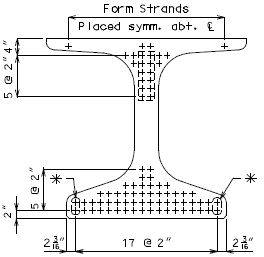

Minimum Spacing of Prestressing Strands

Spacing between each pretressing strand shall not be less than the larger of:

- A clear distance of 1.33 x Maximum Aggregate Size

- Center-to-center spacing of 2" for 0.6" strand diameter

- Center-to-center spacing of 1.75" for 0.5" strand diameter

751.22.3.2 MoDOT Standard Girders

751.22.3.2.1 Beam Type 2 Dimensions/Strand Arrangements

| GIRDERS 2A THRU 2C

= 310.9 SQ. IN. |

GIRDER 2A

(11 STRANDS) |

GIRDER 2B

(12 STRANDS) |

| = 310.9 SQ. IN. = 14.08 IN. |

GROUP I |

GROUP II |

Numbers shown on girders relate to strand locations. |

ATTENTION: Location of harped strands shown in top flange are at end of girder and harped strands in bottom flange are at centerline.

If the web thickness is required to be increased, then the top and bottom flanges are to be increased by the same amount. (1" increments, 2" max.)

751.22.3.2.2 Beam Type 3 Dimensions/Strand Arrangements

| GIRDERS 3A THRU 3B

= 381.9 SQ. IN. |

GIRDER 3A

(11 STRANDS) |

GIRDER 3B

(12 STRANDS) |

| Note: Investigate the possibility of using all straight strands when strength check of a hold-down device exceeds allowable. Strand arrangements shown for Girders 3A thru 3B have straight strands only. Strand arrangements other than those shown may be investigated by the designer. |

| = 381.9 SQ. IN. = 17.08 IN. |

GROUP I |

GROUP II |

Numbers shown on girders relate to strand locations. |

ATTENTION: Location of harped strands shown in top flange are at end of girder and harped strands in bottom flange are at centerline.

If the web thickness is required to be increased, then the top and bottom flanges are to be increased by the same amount. (1" increments, 2" max.)

751.22.3.2.3 Beam Type 4 Dimensions/Strand Arrangements

| GIRDERS 4A THRU 4C

= 428.9 SQ. IN. |

GIRDER 4A

(10 STRANDS) |

GIRDER 4B

(11 STRANDS) |

GIRDERS 4C |

|

| = 428.9 SQ. IN. = 19.54 IN. |

GROUP I |

GROUP II |

Numbers shown on girders relate to strand locations. |

ATTENTION: Location of harped strands shown in top flange are at end of girder and harped strands in bottom flange are at centerline.

If the web thickness is required to be increased, then the top and bottom flanges are to be increased by the same amount. (1" increments, 2" max.)

751.22.3.2.4 Beam Type 6 Dimensions/Strand Arrangements

|

|

GROUP I |

Numbers shown on girders relate to strand locations. |

ATTENTION: Location of harped strands shown in top flange are at end of girder and harped strands in bottom flange are at centerline.

If the web thickness is required to be increased, then the top and bottom flanges are to be increased by the same amount. (1" increments, 2" max.)

751.22.3.2.5 Beam Type 7 Dimensions/Strand Arrangements

|

|

GROUP I |

Numbers shown on girders relate to strand locations. |

ATTENTION: Location of harped strands shown in top flange are at end of girder and harped strands in bottom flange are at centerline.

751.22.3.3 NU Standard Girders

- Note: Strand arrangements shall start at the bottom row and then move up for the most efficient design.

751.22.3.4 Beam Section Properties Tables - Conventional Concrete Strength

The properties of prestressed I-girders in the following tables are valid for = 4.5 ksi and = 6 ksi. The modular ratio , , is 8 for the initial moment of inertia, , and 7 for the final moment of inertia, .

Note: Moments of inertia, and are computed based on transformed non-composite section and are used in camber calculations.

Definitions used in tables are:

| Section Area | = | Gross area of girder, (in.2) |

| Section | = | Distance from bottom of girder to center of gravity of non-transformed non-composite section, (in.) |

| = | Moment of inertia of non-transformed non-composite section, (in.4) | |

| Depth | = | Height of girder, (in.) |

| Strand size | = | Strand diameter, (in.) |

| e1* | = | Eccentricity between centroid of straight strands (CSS) and center of gravity of non-transformed non-composite section (CGB) as shown in figure below, (in.) |

| e2* | = | Eccentricity between centroid of harped strands (CHS) and center of gravity of non-transformed non-composite section (CGB) at midspan as shown in figure below, (in.) |

| e3* | = | Eccentricity between centroid of harped strands (CHS) and center of gravity of non-transformed non-composite section (CGB) at the end of girder as shown in figure below, (in.) |

A more accurate value can be used based on transformed non-composite section. The final camber calculation will not be significantly different using values between transformed and non-transformed sections.

Steps for detailing strand patterns from Prestressed Beam Tables

- For strand locations at mid-span of girder: Look up the "Total Number of Strands" value for the corresponding strand pattern number. The strands will then be located at that number and all numbers below that number. Ex. For 14 total strands, the strands will be placed at all locations numbered ≤14.

- For harped strand locations at end of girder: Look up the "Number of Harped Strands" value for the corresponding strand pattern number. The strands will then be located at that number and all numbers below that number. Ex. For 6 harped strands, the strands will be placed at all locations numbered ≤6.

- GROUP I

Section Properties

Beam Type 2 -- 6" Web

| Section Area = | 310.9 | in2 |

| ||||||||||||||||

| Section = | 14.08 | in | |||||||||||||||||

| = | 33,974 | in4 | |||||||||||||||||

| Depth= | 32 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Iinitial | Ifinal | ||||||||||

| # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars, 2-#6 | |

| Group | 1 | 8 | 4 | 4 | 11.08 | 11.08 | 13.92 | 36,147 | 36,627 | 35,837 | 36,248 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 2 | 10 | 4 | 6 | 11.41 | 11.08 | 13.92 | 36,453 | 36,938 | 36,100 | 36,515 |

| 3 | 12 | 6 | 6 | 11.41 | 10.08 | 12.92 | 36,587 | 37,075 | 36,215 | 36,632 | |

| 4 | 14 | 6 | 8 | 11.08 | 10.08 | 12.92 | 36,794 | 37,286 | 36,394 | 36,814 | |

| 5 | 16 | 8 | 8 | 11.08 | 9.08 | 11.92 | 36,866 | 37,360 | 36,456 | 36,878 | |

| 6 | 18 | 8 | 10 | 10.48 | 9.08 | 11.92 | 36,994 | 37,491 | 36,568 | 36,992 | |

| Group | 7 | 8 | 2 | 6 | 11.41 | 10.08 | 14.92 | 36,147 | 36,627 | 35,837 | 36,248 |

| II | 8 | 10 | 2 | 8 | 11.58 | 10.08 | 14.92 | 36,453 | 36,938 | 36,100 | 36,515 |

| 9 | 12 | 4 | 8 | 11.08 | 11.08 | 13.92 | 36,663 | 37,151 | 36,280 | 36,698 | |

| 10 | 14 | 4 | 10 | 11.28 | 9.08 | 13.92 | 36,794 | 37,286 | 36,394 | 36,814 | |

| 11 | 16 | 6 | 10 | 11.28 | 8.08 | 12.92 | 36,866 | 37,360 | 36,456 | 36,878 | |

| 12 | 18 | 6 | 12 | 10.75 | 8.08 | 12.92 | 36,994 | 37,491 | 36,568 | 36,992 | |

| 13 | 20 | 6 | 14 | 10.65 | 6.08 | 12.92 | 37,024 | 37,522 | 36,594 | 37,019 | |

Section Properties

Beam Type 2 -- 7" Web

| Section Area = | 342.9 | in2 |

| ||||||||||||||||

| Section = | 14.26 | in | |||||||||||||||||

| = | 36,812 | in4 | |||||||||||||||||

| Depth= | 32 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Iinitial | Ifinal | ||||||||||

| # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 | |

| Group | 1 | 8 | 4 | 4 | 11.26 | 11.26 | 13.74 | 38,994 | 39,464 | 38,683 | 39,085 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 2 | 10 | 4 | 6 | 11.59 | 11.26 | 13.74 | 39,310 | 39,784 | 38,954 | 39,360 |

| 3 | 12 | 6 | 6 | 11.59 | 10.26 | 12.74 | 39,450 | 39,927 | 39,075 | 39,482 | |

| 4 | 14 | 6 | 8 | 11.26 | 10.26 | 12.74 | 39,666 | 40,146 | 39,261 | 39,671 | |

| 5 | 16 | 8 | 8 | 11.26 | 9.26 | 11.74 | 39,742 | 40,225 | 39,327 | 39,739 | |

| 6 | 18 | 8 | 10 | 10.66 | 9.26 | 11.74 | 39,877 | 40,363 | 39,444 | 39,858 | |

| Group | 7 | 8 | 2 | 6 | 11.59 | 10.26 | 14.74 | 38,994 | 39,464 | 38,683 | 39,085 |

| II | 8 | 10 | 2 | 8 | 11.76 | 10.26 | 14.74 | 39,310 | 39,784 | 38,954 | 39,360 |

| 9 | 12 | 4 | 8 | 11.26 | 11.26 | 13.74 | 39,528 | 40,005 | 39,142 | 39,550 | |

| 10 | 14 | 4 | 10 | 11.46 | 9.26 | 13.74 | 39,666 | 40,146 | 39,261 | 39,671 | |

| 11 | 16 | 6 | 10 | 11.46 | 8.26 | 12.74 | 39,742 | 40,225 | 39,327 | 39,739 | |

| 12 | 18 | 6 | 12 | 10.93 | 8.26 | 12.74 | 39,877 | 40,363 | 39,444 | 39,858 | |

| 13 | 20 | 6 | 14 | 10.83 | 6.26 | 12.74 | 39,910 | 39,473 | 39,473 | 39,888 | |

Section Properties

Beam Type 2 -- 8" Web

| Section Area = | 374.9 | in2 |

| ||||||||||||||||

| Section = | 14.41 | in | |||||||||||||||||

| = | 39,632 | in4 | |||||||||||||||||

| Depth= | 32 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Iinitial | Ifinal | ||||||||||

| # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 | |

| Group | 1 | 8 | 4 | 4 | 11.41 | 11.41 | 13.59 | 41,823 | 42,283 | 41,510 | 41,905 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 2 | 10 | 4 | 6 | 11.74 | 11.41 | 13.59 | 42,147 | 42,611 | 41,789 | 42,186 |

| 3 | 12 | 6 | 6 | 11.74 | 10.41 | 12.59 | 42,292 | 42,760 | 41,914 | 42,313 | |

| 4 | 14 | 6 | 8 | 11.41 | 10.41 | 12.59 | 42,515 | 42,985 | 42,106 | 42,508 | |

| 5 | 16 | 8 | 8 | 11.41 | 9.41 | 11.59 | 42,596 | 43,068 | 42,176 | 42,579 | |

| 6 | 18 | 8 | 10 | 10.81 | 9.41 | 11.59 | 42,737 | 43,212 | 42,298 | 42,703 | |

| Group | 7 | 8 | 2 | 6 | 11.74 | 10.41 | 14.59 | 41,823 | 42,283 | 41,510 | 41,905 |

| II | 8 | 10 | 2 | 8 | 11.91 | 10.41 | 14.59 | 42,147 | 42,611 | 41,789 | 42,186 |

| 9 | 12 | 4 | 8 | 11.41 | 11.41 | 13.59 | 42,371 | 42,839 | 41,982 | 42,382 | |

| 10 | 14 | 4 | 10 | 11.61 | 9.41 | 13.59 | 42,515 | 42,985 | 42,106 | 42,508 | |

| 11 | 16 | 6 | 10 | 11.61 | 8.41 | 12.59 | 42,596 | 43,068 | 42,176 | 42,579 | |

| 12 | 18 | 6 | 12 | 11.08 | 8.41 | 12.59 | 42,737 | 43,212 | 42,298 | 42,703 | |

| 13 | 20 | 6 | 14 | 10.98 | 6.41 | 12.59 | 42,772 | 43,249 | 42,329 | 42,736 | |

Section Properties

Beam Type 3 -- 6" Web

| Section Area = | 381.9 | in2 |

| ||||||||||||||||

| Section = | 17.08 | in | |||||||||||||||||

| = | 61,841 | in4 | |||||||||||||||||

| Depth= | 39 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Cont. | Iinitial | Ifinal | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Span | # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 |

| Group | 1 | 8 | 4 | 4 | 13.08 | 14.08 | 17.92 | 65,179 | 65,930 | 64,702 | 65,346 |

| I | 2 | 10 | 4 | 6 | 13.75 | 14.08 | 17.92 | 65,659 | 66,415 | 65,114 | 65,762 |

| 3 | 12 | 4 | 8 | 13.58 | 14.08 | 17.92 | 66,014 | 66,776 | 65,421 | 66,072 | |

| 4 | 14 | 6 | 8 | 13.58 | 13.08 | 16.92 | 66,265 | 67,032 | 65,637 | 66,292 | |

| 5 | 16 | 6 | 10 | 13.48 | 13.08 | 16.92 | 66,614 | 67,386 | 65,938 | 66,597 | |

| 6 | 18 | 8 | 10 | 13.48 | 12.08 | 15.92 | 66,776 | 67,552 | 66,079 | 66,740 | |

| 7 | 20 | 8 | 12 | 13.08 | 12.08 | 15.92 | 67,020 | 67,799 | 66,290 | 66,954 | |

| 8 | 22 | 8 | 14 | 12.51 | 12.08 | 15.92 | 67,178 | 67,961 | 66,427 | 67,095 | |

| 9 | 24 | 10 | 14 | 12.51 | 11.08 | 14.92 | 67,270 | 68,056 | 66,508 | 67,177 | |

| Group | 10 | 8 | 2 | 6 | 13.75 | 13.08 | 18.92 | 65,179 | 65,930 | 64,702 | 65,346 |

| II | 11 | 10 | 2 | 8 | 14.08 | 13.08 | 18.92 | 65,659 | 66,415 | 65,114 | 65,762 |

| 12 | 12 | 2 | 10 | 13.88 | 13.08 | 18.92 | 66,014 | 66,776 | 65,421 | 66,072 | |

| 13 | 14 | 4 | 10 | 13.48 | 14.08 | 17.92 | 66,366 | 67,134 | 65,724 | 66,379 | |

| 14 | 16 | 4 | 12 | 13.75 | 12.08 | 17.92 | 66,614 | 67,386 | 65,938 | 66,597 | |

| 15 | 18 | 6 | 12 | 13.75 | 11.08 | 16.92 | 66,776 | 67,552 | 66,079 | 66,740 | |

| 16 | 20 | 6 | 14 | 13.37 | 11.08 | 16.92 | 67,020 | 67,799 | 66,290 | 66,954 | |

| 17 | 22 | 6 | 16 | 12.83 | 11.08 | 16.92 | 67,178 | 67,961 | 66,427 | 67,095 | |

| 18 | 24 | 8 | 16 | 12.83 | 10.08 | 15.92 | 67,270 | 68,056 | 66,508 | 67,177 | |

Section Properties

Beam Type 3 -- 7" Web

| Section Area = | 420.9 | in2 |

| ||||||||||||||||

| Section = | 17.31 | in | |||||||||||||||||

| = | 66,991 | in4 | |||||||||||||||||

| Depth= | 39 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Cont. | Iinitial | Ifinal | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Span | # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 |

| Group | 1 | 8 | 4 | 4 | 13.31 | 14.31 | 17.69 | 70,343 | 71,077 | 69,865 | 70,493 |

| I | 2 | 10 | 4 | 6 | 13.98 | 14.31 | 17.69 | 70,838 | 71,577 | 70,289 | 70,922 |

| 3 | 12 | 4 | 8 | 13.81 | 14.31 | 17.69 | 71,207 | 71,951 | 70,607 | 71,243 | |

| 4 | 14 | 6 | 8 | 13.81 | 13.31 | 16.69 | 71,469 | 72,218 | 70,833 | 71,473 | |

| 5 | 16 | 6 | 10 | 13.71 | 13.31 | 16.69 | 71,832 | 72,585 | 71,146 | 71,789 | |

| 6 | 18 | 8 | 10 | 13.71 | 12.31 | 15.69 | 72,004 | 72,760 | 71,295 | 71,940 | |

| 7 | 20 | 8 | 12 | 13.31 | 12.31 | 15.69 | 72,259 | 73,019 | 71,516 | 72,164 | |

| 8 | 22 | 8 | 14 | 12.74 | 12.31 | 15.69 | 72,427 | 73,190 | 71,662 | 72,312 | |

| 9 | 24 | 10 | 14 | 12.74 | 11.31 | 14.69 | 72,526 | 73,292 | 71,749 | 72,401 | |

| Group | 10 | 8 | 2 | 6 | 13.98 | 13.31 | 18.69 | 70,343 | 71,077 | 69,865 | 70,493 |

| II | 11 | 10 | 2 | 8 | 14.31 | 13.31 | 18.69 | 70,838 | 71,577 | 70,289 | 70,922 |

| 12 | 12 | 2 | 10 | 14.11 | 13.31 | 18.69 | 71,207 | 71,951 | 70,607 | 71,243 | |

| 13 | 14 | 4 | 10 | 13.71 | 14.31 | 17.69 | 71,572 | 72,322 | 70,922 | 71,562 | |

| 14 | 16 | 4 | 12 | 13.98 | 12.31 | 17.69 | 71,832 | 72,585 | 71,146 | 71,789 | |

| 15 | 18 | 6 | 12 | 13.98 | 11.31 | 16.69 | 72,004 | 72,760 | 71,295 | 71,940 | |

| 16 | 20 | 6 | 14 | 13.60 | 11.31 | 16.69 | 72,259 | 73,019 | 71,516 | 72,164 | |

| 17 | 22 | 6 | 16 | 13.06 | 11.31 | 16.69 | 72,427 | 73,190 | 71,662 | 72,312 | |

| 18 | 24 | 8 | 16 | 13.06 | 10.31 | 15.69 | 72,526 | 73,292 | 71,749 | 72,401 | |

Section Properties

Beam Type 3 -- 8" Web

| Section Area = | 459.9 | in2 |

| ||||||||||||||||

| Section = | 17.49 | in | |||||||||||||||||

| = | 72,106 | in4 | |||||||||||||||||

| Depth= | 39 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Cont. | Iinitial | Ifinal | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Span | # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 |

| Group | 1 | 8 | 4 | 4 | 13.49 | 14.49 | 17.51 | 75,470 | 76,191 | 74,990 | 75,607 |

| I | 2 | 10 | 4 | 6 | 14.16 | 14.49 | 17.51 | 75,977 | 76,703 | 75,425 | 76,046 |

| 3 | 12 | 4 | 8 | 13.99 | 14.49 | 17.51 | 76,357 | 77,087 | 75,752 | 76,376 | |

| 4 | 14 | 6 | 8 | 13.99 | 13.49 | 16.51 | 76,628 | 77,363 | 75,986 | 76,613 | |

| 5 | 16 | 6 | 10 | 13.89 | 13.49 | 16.51 | 77,002 | 77,740 | 76,308 | 76,939 | |

| 6 | 18 | 8 | 10 | 13.89 | 12.49 | 15.51 | 77,182 | 77,923 | 76,464 | 77,096 | |

| 7 | 20 | 8 | 12 | 13.49 | 12.49 | 15.51 | 77,446 | 78,191 | 76,692 | 77,328 | |

| 8 | 22 | 8 | 14 | 12.92 | 12.49 | 15.51 | 77,622 | 78,370 | 76,845 | 77,483 | |

| 9 | 24 | 10 | 14 | 12.92 | 11.49 | 14.51 | 77,728 | 78,479 | 76,938 | 77,577 | |

| Group | 10 | 8 | 2 | 6 | 14.16 | 13.49 | 18.51 | 75,470 | 76,191 | 74,990 | 75,607 |

| II | 11 | 10 | 2 | 8 | 14.49 | 13.49 | 18.51 | 75,977 | 76,703 | 75,425 | 76,046 |

| 12 | 12 | 2 | 10 | 14.29 | 13.49 | 18.51 | 76,357 | 77,087 | 75,752 | 76,376 | |

| 13 | 14 | 4 | 10 | 13.89 | 14.49 | 17.51 | 76,733 | 77,468 | 76,076 | 76,704 | |

| 14 | 16 | 4 | 12 | 14.16 | 12.49 | 17.51 | 77,002 | 77,740 | 76,308 | 76,939 | |

| 15 | 18 | 6 | 12 | 14.16 | 11.49 | 16.51 | 77,182 | 77,923 | 76,464 | 77,096 | |

| 16 | 20 | 6 | 14 | 13.78 | 11.49 | 16.51 | 77,446 | 78,191 | 76,692 | 77,328 | |

| 17 | 22 | 6 | 16 | 13.24 | 11.49 | 16.51 | 77,622 | 78,370 | 76,845 | 77,483 | |

| 18 | 24 | 8 | 16 | 13.24 | 10.49 | 15.51 | 77,728 | 78,479 | 76,938 | 77,577 | |

Section Properties

Beam Type 4 -- 6" Web

| Section Area = | 428.9 | in2 |

| ||||||||||||||||

| Section = | 19.54 | in | |||||||||||||||||

| = | 92,450 | in4 | |||||||||||||||||

| Depth= | 45 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Cont. | Iinitial | Ifinal | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Span | # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 |

| Group | 1 | 8 | 4 | 4 | 15.54 | 16.54 | 21.46 | 97,077 | 98,118 | 96,416 | 97,308 |

| I | 2 | 10 | 4 | 6 | 16.21 | 16.54 | 21.46 | 97,727 | 98,775 | 96,974 | 97,872 |

| 3 | 12 | 4 | 8 | 16.04 | 16.54 | 21.46 | 98,231 | 99,286 | 97,408 | 98,310 | |

| 4 | 14 | 6 | 8 | 16.04 | 15.54 | 20.46 | 98,608 | 99,669 | 97,733 | 98,640 | |

| 5 | 16 | 6 | 10 | 15.94 | 15.54 | 20.46 | 99,103 | 100,170 | 98,160 | 99,071 | |

| 6 | 18 | 8 | 10 | 15.94 | 14.54 | 19.46 | 99,368 | 100,441 | 98,390 | 99,305 | |

| 7 | 20 | 8 | 12 | 15.54 | 14.54 | 19.46 | 99,735 | 100,813 | 98,707 | 99,626 | |

| 8 | 22 | 8 | 14 | 14.97 | 14.54 | 19.46 | 99,995 | 101,078 | 98,933 | 99,856 | |

| 9 | 24 | 8 | 16 | 15.29 | 12.54 | 19.46 | 100,168 | 101,254 | 99,083 | 100,009 | |

| 10 | 26 | 10 | 16 | 15.29 | 11.54 | 18.46 | 100,271 | 101,360 | 99,174 | 100,102 | |

| 11 | 28 | 10 | 18 | 15.32 | 9.54 | 18.46 | 100,323 | 101,414 | 99,220 | 100,149 | |

| Group | 12 | 8 | 2 | 6 | 16.21 | 15.54 | 22.46 | 97,077 | 98,118 | 96,416 | 97,308 |

| II | 13 | 10 | 2 | 8 | 16.54 | 15.54 | 22.46 | 97,727 | 98,775 | 96,974 | 97,872 |

| 14 | 12 | 4 | 8 | 16.04 | 16.54 | 21.46 | 98,231 | 99,286 | 97,408 | 98,310 | |

| 15 | 14 | 4 | 10 | 15.94 | 16.54 | 21.46 | 98,730 | 99,792 | 97,838 | 98,745 | |

| 16 | 16 | 4 | 12 | 16.21 | 14.54 | 21.46 | 99,103 | 100,170 | 98,160 | 99,071 | |

| 17 | 16 | 6 | 10 | 15.94 | 15.54 | 20.46 | 99,103 | 100,170 | 98,160 | 99,071 | |

| 18 | 18 | 6 | 12 | 16.21 | 13.54 | 20.46 | 99,368 | 100,441 | 98,390 | 99,305 | |

| 19 | 20 | 6 | 14 | 15.83 | 13.54 | 20.46 | 99,735 | 100,813 | 98,707 | 99,626 | |

| 20 | 22 | 6 | 16 | 15.29 | 13.54 | 20.46 | 99,995 | 101,078 | 98,933 | 99,856 | |

| 21 | 24 | 6 | 18 | 15.32 | 11.54 | 20.46 | 100,168 | 101,254 | 99,083 | 100,009 | |

| 22 | 26 | 6 | 20 | 15.14 | 9.54 | 20.46 | 100,271 | 101,360 | 99,174 | 100,102 | |

| 23 | 26 | 8 | 18 | 15.32 | 10.54 | 19.46 | 100,271 | 101,360 | 99,174 | 100,102 | |

| 24 | 28 | 6 | 22 | 14.81 | 7.54 | 20.46 | 100,323 | 101,414 | 99,220 | 100,149 | |

| 25 | 28 | 8 | 20 | 15.14 | 8.54 | 19.46 | 100,323 | 101,414 | 99,220 | 100,149 | |

| 26 | 30 | 8 | 22 | 14.81 | 6.54 | 19.46 | 100,341 | 101,433 | 99,236 | 100,166 | |

| 27 | 32 | 8 | 24 | 14.37 | 4.54 | 19.46 | 100,342 | 101,435 | 99,238 | 100,168 | |

Section Properties

Beam Type 4 -- 7" Web

| Section Area = | 473.9 | in2 |

| ||||||||||||||||

| Section = | 19.82 | in | |||||||||||||||||

| = | 100,400 | in4 | |||||||||||||||||

| Depth= | 45 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Cont. | Iinitial | Ifinal | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Span | # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 |

| Group | 1 | 8 | 4 | 4 | 15.82 | 16.82 | 21.18 | 105,048 | 106,065 | 104,384 | 105,256 |

| I | 2 | 10 | 4 | 6 | 16.49 | 16.82 | 21.18 | 105,719 | 106,743 | 104,960 | 105,837 |

| 3 | 12 | 4 | 8 | 16.32 | 16.82 | 21.18 | 106,242 | 107,272 | 105,410 | 106,291 | |

| 4 | 14 | 6 | 8 | 16.32 | 15.82 | 20.18 | 106,636 | 107,671 | 105,750 | 106,635 | |

| 5 | 16 | 6 | 10 | 16.22 | 15.82 | 20.18 | 107,151 | 108,192 | 106,193 | 107,083 | |

| 6 | 18 | 8 | 10 | 16.22 | 14.82 | 19.18 | 107,431 | 108,476 | 106,436 | 107,328 | |

| 7 | 20 | 8 | 12 | 15.82 | 14.82 | 19.18 | 107,815 | 108,866 | 106,768 | 107,664 | |

| 8 | 22 | 8 | 14 | 15.25 | 14.82 | 19.18 | 108,090 | 109,145 | 107,007 | 107,906 | |

| 9 | 24 | 8 | 16 | 15.57 | 12.82 | 19.18 | 108,275 | 109,334 | 107,168 | 108,070 | |

| 10 | 26 | 10 | 16 | 15.57 | 11.82 | 18.18 | 108,388 | 109,449 | 107,266 | 108,171 | |

| 11 | 28 | 10 | 18 | 15.60 | 9.82 | 18.18 | 108,446 | 109,510 | 107,318 | 108,224 | |

| Group | 12 | 8 | 2 | 6 | 16.49 | 15.82 | 22.18 | 105,048 | 106,065 | 104,384 | 105,256 |

| II | 13 | 10 | 2 | 8 | 16.82 | 15.82 | 22.18 | 105,719 | 106,743 | 104,960 | 105,837 |

| 14 | 12 | 4 | 8 | 16.32 | 16.82 | 21.18 | 106,242 | 107,272 | 105,410 | 106,291 | |

| 15 | 14 | 4 | 10 | 16.22 | 16.82 | 21.18 | 106,760 | 107,796 | 105,857 | 106,742 | |

| 16 | 16 | 4 | 12 | 16.49 | 14.82 | 21.18 | 107,151 | 108,192 | 106,193 | 107,083 | |

| 17 | 16 | 6 | 10 | 16.22 | 15.82 | 20.18 | 107,151 | 108,192 | 106,193 | 107,083 | |

| 18 | 18 | 6 | 12 | 16.49 | 13.82 | 20.18 | 107,431 | 108,476 | 106,436 | 107,328 | |

| 19 | 20 | 6 | 14 | 16.11 | 13.82 | 20.18 | 107,815 | 108,866 | 106,768 | 107,664 | |

| 20 | 22 | 6 | 16 | 15.57 | 13.82 | 20.18 | 108,090 | 109,145 | 107,007 | 107,906 | |

| 21 | 24 | 6 | 18 | 15.60 | 11.82 | 20.18 | 108,275 | 109,334 | 107,168 | 108,070 | |

| 22 | 26 | 6 | 20 | 15.42 | 9.82 | 20.18 | 108,388 | 109,449 | 107,266 | 108,171 | |

| 23 | 26 | 8 | 18 | 15.60 | 10.82 | 19.18 | 108,388 | 109,449 | 107,266 | 108,171 | |

| 24 | 28 | 6 | 22 | 15.09 | 7.82 | 20.18 | 108,446 | 109,510 | 107,318 | 108,224 | |

| 25 | 28 | 8 | 20 | 15.42 | 8.82 | 19.18 | 108,446 | 109,510 | 107,318 | 108,224 | |

| 26 | 30 | 8 | 22 | 15.09 | 6.82 | 19.18 | 108,469 | 109,533 | 107,338 | 108,245 | |

| 27 | 32 | 8 | 24 | 14.65 | 4.82 | 19.18 | 108,472 | 109,537 | 107,341 | 108,248 | |

Section Properties

Beam Type 4 -- 8" Web

| Section Area = | 518.9 | in2 |

| ||||||||||||||||

| Section = | 20.06 | in | |||||||||||||||||

| = | 108,288 | in4 | |||||||||||||||||

| Depth= | 45 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Cont. | Iinitial | Ifinal | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Span | # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 |

| Group | 1 | 8 | 4 | 4 | 16.06 | 17.06 | 20.94 | 112,955 | 113,952 | 112,289 | 113,143 |

| I | 2 | 10 | 4 | 6 | 16.73 | 17.06 | 20.94 | 113,645 | 114,648 | 112,881 | 113,739 |

| 3 | 12 | 4 | 8 | 16.56 | 17.06 | 20.94 | 114,185 | 115,193 | 113,345 | 114,208 | |

| 4 | 14 | 6 | 8 | 16.56 | 16.06 | 19.94 | 114,594 | 115,607 | 113,698 | 114,563 | |

| 5 | 16 | 6 | 10 | 16.46 | 16.06 | 19.94 | 115,126 | 116,144 | 114,156 | 115,026 | |

| 6 | 18 | 8 | 10 | 16.46 | 15.06 | 18.94 | 115,419 | 116,442 | 114,409 | 115,282 | |

| 7 | 20 | 8 | 12 | 16.06 | 15.06 | 18.94 | 115,818 | 116,846 | 114,755 | 115,631 | |

| 8 | 22 | 8 | 14 | 15.49 | 15.06 | 18.94 | 116,107 | 117,138 | 115,004 | 115,884 | |

| 9 | 24 | 8 | 16 | 15.81 | 13.06 | 18.94 | 116,303 | 117,337 | 115,175 | 116,057 | |

| 10 | 26 | 10 | 16 | 15.81 | 12.06 | 17.94 | 116,424 | 117,461 | 115,281 | 116,165 | |

| 11 | 28 | 10 | 18 | 15.84 | 10.06 | 17.94 | 116,489 | 117,528 | 115,338 | 116,223 | |

| Group | 12 | 8 | 2 | 6 | 16.73 | 16.06 | 21.94 | 112,955 | 113,952 | 112,289 | 113,143 |

| II | 13 | 10 | 2 | 8 | 17.06 | 16.06 | 21.94 | 113,645 | 114,648 | 112,881 | 113,739 |

| 14 | 12 | 4 | 8 | 16.56 | 17.06 | 20.94 | 114,185 | 115,193 | 113,345 | 114,208 | |

| 15 | 14 | 4 | 10 | 16.46 | 17.06 | 20.94 | 114,720 | 115,734 | 113,806 | 114,673 | |

| 16 | 16 | 4 | 12 | 16.73 | 15.06 | 20.94 | 115,126 | 116,144 | 114,156 | 115,026 | |

| 17 | 16 | 6 | 10 | 16.46 | 16.06 | 19.94 | 115,126 | 116,144 | 114,156 | 115,026 | |

| 18 | 18 | 6 | 12 | 16.73 | 14.06 | 19.94 | 115,419 | 116,442 | 114,409 | 115,282 | |

| 19 | 20 | 6 | 14 | 16.35 | 14.06 | 19.94 | 115,818 | 116,846 | 114,755 | 115,631 | |

| 20 | 22 | 6 | 16 | 15.81 | 14.06 | 19.94 | 116,107 | 117,138 | 115,004 | 115,884 | |

| 21 | 24 | 6 | 18 | 15.84 | 12.06 | 19.94 | 116,303 | 117,337 | 115,175 | 116,057 | |

| 22 | 26 | 6 | 20 | 15.66 | 10.06 | 19.94 | 116,424 | 117,461 | 115,281 | 116,165 | |

| 23 | 26 | 8 | 18 | 15.84 | 11.06 | 18.94 | 116,424 | 117,461 | 115,281 | 116,165 | |

| 24 | 28 | 6 | 22 | 15.33 | 8.06 | 19.94 | 116,489 | 117,528 | 115,338 | 116,223 | |

| 25 | 28 | 8 | 20 | 15.66 | 9.06 | 18.94 | 116,489 | 117,528 | 115,338 | 116,223 | |

| 26 | 30 | 8 | 22 | 15.33 | 7.06 | 18.94 | 116,515 | 117,555 | 115,361 | 116,247 | |

| 27 | 32 | 8 | 24 | 14.89 | 5.06 | 18.94 | 116,520 | 117,560 | 115,366 | 116,252 | |

Section Properties

Beam Type 6 -- 6.5" Web

| Section Area = | 643.6 | in2 |

| ||||||||||||||||

| Section = | 25.92 | in | |||||||||||||||||

| = | 235,735 | in4 | |||||||||||||||||

| Depth= | 54 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Iinitial | Ifinal | ||||||||

| # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#6 |

A1 Bars 2-#6 | |

| Group | 1 | 14 | 4 | 10 | 23.52 | 22.92 | 23.08 | 248,115 | 246,353 |

|---|---|---|---|---|---|---|---|---|---|

| I | 2 | 16 | 4 | 12 | 23.25 | 22.92 | 23.08 | 249,115 | 247,213 |

| 3 | 18 | 6 | 12 | 23.25 | 21.92 | 22.08 | 249,933 | 247,918 | |

| 4 | 20 | 6 | 14 | 23.06 | 21.92 | 22.08 | 250,920 | 248,769 | |

| 5 | 22 | 6 | 16 | 22.92 | 21.92 | 22.08 | 251,901 | 249,616 | |

| 6 | 24 | 8 | 16 | 22.92 | 20.92 | 21.08 | 252,545 | 250,173 | |

| 7 | 26 | 8 | 18 | 22.59 | 20.92 | 21.08 | 253,342 | 250,862 | |

| 8 | 28 | 8 | 20 | 22.32 | 20.92 | 21.08 | 254,133 | 251,547 | |

| 9 | 30 | 10 | 20 | 22.32 | 19.92 | 20.08 | 254,626 | 251,975 | |

| 10 | 32 | 10 | 22 | 22.10 | 19.92 | 20.08 | 255,408 | 252,653 | |

| 11 | 34 | 10 | 24 | 21.75 | 19.92 | 20.08 | 256,032 | 253,195 | |

| 12 | 36 | 10 | 26 | 21.46 | 19.92 | 20.08 | 256,651 | 253,734 | |

| 13 | 38 | 12 | 26 | 21.46 | 18.92 | 19.08 | 257,011 | 254,048 |

Section Properties

Beam Type 6 -- 7.5" Web

| Section Area = | 697.6 | in2 |

| ||||||||||||||||

| Section = | 26.00 | in | |||||||||||||||||

| = | 248,915 | in4 | |||||||||||||||||

| Depth= | 54 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Iinitial | Ifinal | ||||||||

| # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#6 |

A1 Bars 2-#6 | |

| Group | 1 | 14 | 4 | 10 | 23.60 | 23.00 | 23.00 | 262,852 | 260,864 |

|---|---|---|---|---|---|---|---|---|---|

| I | 2 | 16 | 4 | 12 | 23.33 | 23.00 | 23.00 | 263,868 | 261,737 |

| 3 | 18 | 6 | 12 | 23.33 | 22.00 | 22.00 | 264,701 | 262,454 | |

| 4 | 20 | 6 | 14 | 23.14 | 22.00 | 22.00 | 265,707 | 263,319 | |

| 5 | 22 | 6 | 16 | 23.00 | 22.00 | 22.00 | 266,706 | 264,180 | |

| 6 | 24 | 8 | 16 | 23.00 | 21.00 | 21.00 | 267,365 | 264,749 | |

| 7 | 26 | 8 | 18 | 22.67 | 21.00 | 21.00 | 268,178 | 265,452 | |

| 8 | 28 | 8 | 20 | 22.40 | 21.00 | 21.00 | 268,987 | 266,150 | |

| 9 | 30 | 10 | 20 | 22.40 | 20.00 | 20.00 | 269,493 | 266,589 | |

| 10 | 32 | 10 | 22 | 22.18 | 20.00 | 20.00 | 270,294 | 267,282 | |

| 11 | 34 | 10 | 24 | 21.83 | 20.00 | 20.00 | 270,933 | 267,836 | |

| 12 | 36 | 10 | 26 | 21.54 | 20.00 | 20.00 | 271,569 | 268,387 | |

| 13 | 38 | 12 | 26 | 21.54 | 19.00 | 19.00 | 271,941 | 268,712 |

Section Properties

Beam Type 6 -- 8.5" Web

| Section Area = | 751.6 | in2 |

| ||||||||||||||||

| Section = | 26.07 | in | |||||||||||||||||

| = | 262,087 | in4 | |||||||||||||||||

| Depth= | 54 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Iinitial | Ifinal | ||||||||

| # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#6 |

A1 Bars 2-#6 | |

| Group | 1 | 14 | 4 | 10 | 23.67 | 23.07 | 22.93 | 276,043 | 274,052 |

|---|---|---|---|---|---|---|---|---|---|

| I | 2 | 16 | 4 | 12 | 23.40 | 23.07 | 22.93 | 277,068 | 274,932 |

| 3 | 18 | 6 | 12 | 23.40 | 22.07 | 21.93 | 277,908 | 275,656 | |

| 4 | 20 | 6 | 14 | 23.21 | 22.07 | 21.93 | 278,922 | 276,528 | |

| 5 | 22 | 6 | 16 | 23.07 | 22.07 | 21.93 | 279,930 | 277,396 | |

| 6 | 24 | 8 | 16 | 23.07 | 21.07 | 20.93 | 280,596 | 277,971 | |

| 7 | 26 | 8 | 18 | 22.74 | 21.07 | 20.93 | 281,418 | 278,680 | |

| 8 | 28 | 8 | 20 | 22.47 | 21.07 | 20.93 | 282,236 | 279,386 | |

| 9 | 30 | 10 | 20 | 22.47 | 20.07 | 19.93 | 282,750 | 279,831 | |

| 10 | 32 | 10 | 22 | 22.25 | 20.07 | 19.93 | 283,559 | 280,531 | |

| 11 | 34 | 10 | 24 | 21.90 | 20.07 | 19.93 | 284,207 | 281,093 | |

| 12 | 36 | 10 | 26 | 21.61 | 20.07 | 19.93 | 284,851 | 281,651 | |

| 13 | 38 | 12 | 26 | 21.61 | 19.07 | 18.93 | 285,230 | 281,981 |

Section Properties

Beam Type 7 -- 6" Web

Bulb-Tee Girder

| Section Area = | 787.4 | in2 |

| ||||||||||||||||

| Section = | 37.58 | in | |||||||||||||||||

| = | 571,047 | in4 | |||||||||||||||||

| Depth= | 72.5 | in | |||||||||||||||||

| Strand Size= | ½ | in | |||||||||||||||||

| = | 4.5 | ksi | |||||||||||||||||

| = | 6 | ksi |

| Cont. | Iinitial | Ifinal | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Span | # | T | H | S | e1 | e2 | e3 | A1 Bars 4-#6 |

A1 Bars 4-#6 |

| Group | 1 | 14 | 4 | 10 | 35.58 | 34.58 | 29.92 | 603,636 | 598,983 |

| I | 2 | 16 | 4 | 12 | 35.25 | 34.58 | 29.92 | 606,025 | 601,033 |

| 3 | 18 | 6 | 12 | 35.25 | 33.58 | 28.92 | 608,125 | 602,838 | |

| 4 | 20 | 6 | 14 | 35.01 | 33.58 | 28.92 | 610,490 | 604,871 | |

| 5 | 22 | 6 | 16 | 34.83 | 33.58 | 28.92 | 612,843 | 606,895 | |

| 6 | 24 | 8 | 16 | 34.83 | 32.58 | 27.92 | 614,652 | 608,453 | |

| 7 | 26 | 8 | 18 | 34.69 | 32.58 | 27.92 | 616,981 | 610,459 | |

| 8 | 28 | 8 | 20 | 34.58 | 32.58 | 27.92 | 619,299 | 612,457 | |

| 9 | 30 | 10 | 20 | 34.58 | 31.58 | 26.92 | 620,839 | 613,788 | |

| 10 | 32 | 10 | 22 | 34.31 | 31.58 | 26.92 | 622,864 | 615,536 | |

| 11 | 34 | 10 | 24 | 34.08 | 31.58 | 26.92 | 624,878 | 617,276 | |

| 12 | 36 | 10 | 26 | 33.89 | 31.58 | 26.92 | 626,881 | 619,009 | |

| 13 | 38 | 10 | 28 | 33.58 | 31.58 | 26.92 | 628,622 | 620,517 | |

| 14 | 40 | 12 | 28 | 33.58 | 30.58 | 25.92 | 629,902 | 621,627 |

751.22.3.5 Beam Section Properties Tables - Higher Concrete Strength

The properties of prestressed I-girders in the following tables are valid for = 5 ksi and = 7 ksi. The modular ratio , , is 7 for the initial moment of inertia, , and 6 for the final moment of inertia, .

Note: Moments of inertia, and are computed based on transformed non-composite section and are used in camber calculations. A1 Bar locations are assumed at 3" from the top of girder.

Definitions used in tables are:

| Section Area | = | Gross area of girder, (in.2) |

| Section | = | Distance from bottom of girder to center of gravity of non-transformed non-composite section, (in.) |

| = | Moment of inertia of non-transformed non-composite section, (in.4) | |

| Depth | = | Height of girder, (in.) |

| Strand size | = | Strand diameter, (in.) |

| e1* | = | Eccentricity between centroid of straight strands (CSS) and center of gravity of non-transformed non-composite section (CGB) as shown in figure below, (in.) |

| e2* | = | Eccentricity between centroid of harped strands (CHS) and center of gravity of non-transformed non-composite section (CGB) at midspan as shown in figure below, (in.) |

| e3* | = | Eccentricity between centroid of harped strands (CHS) and center of gravity of non-transformed non-composite section (CGB) at the end of girder as shown in figure below, (in.) |

A more accurate value can be used based on transformed non-composite section. The final camber calculation will not be significantly different using values between transformed and non-transformed sections.

Steps for detailing strand patterns from Prestressed Beam Tables

- For strand locations at mid-span of girder: Look up the "Total Number of Strands" value for the corresponding strand pattern number. The strands will then be located at that number and all numbers below that number. Ex. For 14 total strands, the strands will be placed at all locations numbered ≤14.

- For harped strand locations at end of girder: Look up the "Number of Harped Strands" value for the corresponding strand pattern number. The strands will then be located at that number and all numbers below that number. Ex. For 6 harped strands, the strands will be placed at all locations numbered ≤6.

- GROUP I

Section Properties

Beam Type 2 -- 6" Web

| Section Area = | 310.9 | in2 |

| ||||||||||||||||

| Section = | 14.08 | in | |||||||||||||||||

| = | 33,974 | in4 | |||||||||||||||||

| Depth= | 32 | in | |||||||||||||||||

| Strand Size= | 0.6 | in | |||||||||||||||||

| = | 5 | ksi | |||||||||||||||||

| = | 7 | ksi |

| Iinitial | Ifinal | ||||||||||

| # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars, 2-#6 | |

| Group | 1 | 8 | 4 | 4 | 11.08 | 11.08 | 13.92 | 36,407 | 36,838 | 36,062 | 36,429 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 2 | 10 | 4 | 6 | 11.41 | 11.08 | 13.92 | 36,828 | 37,265 | 36,424 | 36,797 |

| 3 | 12 | 6 | 6 | 11.41 | 10.08 | 12.92 | 36,983 | 37,424 | 36,559 | 36,935 | |

| 4 | 14 | 6 | 8 | 11.08 | 10.08 | 12.92 | 37,265 | 37,711 | 36,804 | 37,183 | |

| 5 | 16 | 8 | 8 | 11.08 | 9.08 | 11.92 | 37,304 | 37,753 | 36,839 | 37,221 | |

| 6 | 18 | 8 | 10 | 10.48 | 9.08 | 11.92 | 37,465 | 37,917 | 36,980 | 37,364 | |

| Group | 7 | 8 | 2 | 6 | 11.41 | 10.08 | 14.92 | 36,407 | 36,837 | 36,061 | 36,429 |

| II | 8 | 10 | 2 | 8 | 11.58 | 10.08 | 14.92 | 36,829 | 37,265 | 36,425 | 36,797 |

| 9 | 12 | 4 | 8 | 11.08 | 11.08 | 13.92 | 37,112 | 37,553 | 36,670 | 37,046 | |

| 10 | 14 | 4 | 10 | 11.28 | 9.08 | 13.92 | 37,265 | 37,711 | 36,804 | 37,183 | |

| 11 | 16 | 6 | 10 | 11.28 | 8.08 | 12.92 | 37,304 | 37,753 | 36,839 | 37,221 | |

| 12 | 18 | 6 | 12 | 10.75 | 8.08 | 12.92 | 37,466 | 37,918 | 36,981 | 37,365 | |

| 13 | 20 | 6 | 14 | 10.65 | 6.08 | 12.92 | 37,409 | 37,864 | 36,934 | 37,320 | |

Section Properties

Beam Type 2 -- 7" Web

| Section Area = | 342.9 | in2 |

| ||||||||||||||||

| Section = | 14.26 | in | |||||||||||||||||

| = | 36,812 | in4 | |||||||||||||||||

| Depth= | 32 | in | |||||||||||||||||

| Strand Size= | 0.6 | in | |||||||||||||||||

| = | 5 | ksi | |||||||||||||||||

| = | 7 | ksi |

| Iinitial | Ifinal | ||||||||||

| # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 | |

| Group | 1 | 8 | 4 | 4 | 11.26 | 11.26 | 13.74 | 39,272 | 39,691 | 38,922 | 39,281 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 2 | 10 | 4 | 6 | 11.59 | 11.26 | 13.74 | 39,706 | 40,132 | 39,297 | 39,660 |

| 3 | 12 | 6 | 6 | 11.59 | 10.26 | 12.74 | 39,871 | 40,300 | 39,440 | 39,806 | |

| 4 | 14 | 6 | 8 | 11.26 | 10.26 | 12.74 | 40,165 | 40,599 | 39,695 | 40,064 | |

| 5 | 16 | 8 | 8 | 11.26 | 9.26 | 11.74 | 40,211 | 40,648 | 39,736 | 40,108 | |

| 6 | 18 | 8 | 10 | 10.66 | 9.26 | 11.74 | 40,382 | 40,822 | 39,885 | 40,259 | |

| Group | 7 | 8 | 2 | 6 | 11.59 | 10.26 | 14.74 | 39,271 | 39,691 | 38,921 | 39,280 |

| II | 8 | 10 | 2 | 8 | 11.76 | 10.26 | 14.74 | 39,707 | 40,133 | 39,297 | 39,660 |

| 9 | 12 | 4 | 8 | 11.26 | 11.26 | 13.74 | 40,002 | 40,432 | 39,553 | 39,919 | |

| 10 | 14 | 4 | 10 | 11.46 | 9.26 | 13.74 | 40,165 | 40,599 | 39,695 | 40,064 | |

| 11 | 16 | 6 | 10 | 11.46 | 8.26 | 12.74 | 40,211 | 40,648 | 39,736 | 40,108 | |

| 12 | 18 | 6 | 12 | 10.93 | 8.26 | 12.74 | 40,383 | 40,823 | 39,886 | 40,260 | |

| 13 | 20 | 6 | 14 | 10.83 | 6.26 | 12.74 | 40,331 | 40,773 | 39,843 | 40,219 | |

Section Properties

Beam Type 2 -- 8" Web

| Section Area = | 374.9 | in2 |

| ||||||||||||||||

| Section = | 14.41 | in | |||||||||||||||||

| = | 39,632 | in4 | |||||||||||||||||

| Depth= | 32 | in | |||||||||||||||||

| Strand Size= | 0.6 | in | |||||||||||||||||

| = | 5 | ksi | |||||||||||||||||

| = | 7 | ksi |

| Iinitial | Ifinal | ||||||||||

| # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 | |

| Group | 1 | 8 | 4 | 4 | 11.41 | 11.41 | 13.59 | 42,114 | 42,525 | 41,761 | 42,113 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 2 | 10 | 4 | 6 | 11.74 | 11.41 | 13.59 | 42,561 | 42,977 | 42,146 | 42,502 |

| 3 | 12 | 6 | 6 | 11.74 | 10.41 | 12.59 | 42,734 | 43,154 | 42,296 | 42,654 | |

| 4 | 14 | 6 | 8 | 11.41 | 10.41 | 12.59 | 43,039 | 43,463 | 42,560 | 42,921 | |

| 5 | 16 | 8 | 8 | 11.41 | 9.41 | 11.59 | 43,091 | 43,518 | 42,607 | 42,970 | |

| 6 | 18 | 8 | 10 | 10.81 | 9.41 | 11.59 | 43,270 | 43,700 | 42,764 | 43,129 | |

| Group | 7 | 8 | 2 | 6 | 11.74 | 10.41 | 14.59 | 42,114 | 42,525 | 41,761 | 42,112 |

| II | 8 | 10 | 2 | 8 | 11.91 | 10.41 | 14.59 | 42,562 | 42,978 | 42,147 | 42,502 |

| 9 | 12 | 4 | 8 | 11.41 | 11.41 | 13.59 | 42,867 | 43,288 | 42,411 | 42,769 | |

| 10 | 14 | 4 | 10 | 11.61 | 9.41 | 13.59 | 43,039 | 43,463 | 42,560 | 42,921 | |

| 11 | 16 | 6 | 10 | 11.61 | 8.41 | 12.59 | 43,091 | 43,518 | 42,607 | 42,970 | |

| 12 | 18 | 6 | 12 | 11.08 | 8.41 | 12.59 | 43,271 | 43,701 | 42,765 | 43,130 | |

| 13 | 20 | 6 | 14 | 10.98 | 6.41 | 12.59 | 43,224 | 43,655 | 42,725 | 43,092 | |

Section Properties

Beam Type 3 -- 6" Web

| Section Area = | 381.9 | in2 |

| ||||||||||||||||

| Section = | 17.08 | in | |||||||||||||||||

| = | 61,841 | in4 | |||||||||||||||||

| Depth= | 39 | in | |||||||||||||||||

| Strand Size= | 0.6 | in | |||||||||||||||||

| = | 5 | ksi | |||||||||||||||||

| = | 7 | ksi |

| Cont. | Iinitial | Ifinal | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Span | # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 |

| Group | 1 | 8 | 4 | 4 | 13.08 | 14.08 | 17.92 | 65,603 | 66,291 | 65,068 | 65,656 |

| I | 2 | 10 | 4 | 6 | 13.75 | 14.08 | 17.92 | 66,265 | 66,962 | 65,638 | 66,233 |

| 3 | 12 | 4 | 8 | 13.58 | 14.08 | 17.92 | 66,753 | 67,457 | 66,060 | 66,660 | |

| 4 | 14 | 6 | 8 | 13.58 | 13.08 | 16.92 | 67,077 | 67,787 | 66,341 | 66,945 | |

| 5 | 16 | 6 | 10 | 13.48 | 13.08 | 16.92 | 67,555 | 68,271 | 66,755 | 67,364 | |

| 6 | 18 | 8 | 10 | 13.48 | 12.08 | 15.92 | 67,723 | 68,444 | 66,903 | 67,516 | |

| 7 | 20 | 8 | 12 | 13.08 | 12.08 | 15.92 | 68,042 | 68,769 | 67,182 | 67,799 | |

| 8 | 22 | 8 | 14 | 12.51 | 12.08 | 15.92 | 68,218 | 68,949 | 67,336 | 67,957 | |

| 9 | 24 | 10 | 14 | 12.51 | 11.08 | 14.92 | 68,260 | 68,994 | 67,376 | 67,998 | |

| Group | 10 | 8 | 2 | 6 | 13.75 | 13.08 | 18.92 | 65,604 | 66,292 | 65,068 | 65,657 |

| II | 11 | 10 | 2 | 8 | 14.08 | 13.08 | 18.92 | 66,264 | 66,961 | 65,637 | 66,232 |

| 12 | 12 | 2 | 10 | 13.88 | 13.08 | 18.92 | 66,753 | 67,457 | 66,060 | 66,660 | |

| 13 | 14 | 4 | 10 | 13.48 | 14.08 | 17.92 | 67,236 | 67,946 | 66,477 | 67,082 | |

| 14 | 16 | 4 | 12 | 13.75 | 12.08 | 17.92 | 67,556 | 68,272 | 66,756 | 67,366 | |

| 15 | 18 | 6 | 12 | 13.75 | 11.08 | 16.92 | 67,725 | 68,445 | 66,904 | 67,517 | |

| 16 | 20 | 6 | 14 | 13.37 | 11.08 | 16.92 | 68,045 | 68,771 | 67,184 | 67,800 | |

| 17 | 22 | 6 | 16 | 12.83 | 11.08 | 16.92 | 68,217 | 68,948 | 67,336 | 67,956 | |

| 18 | 24 | 8 | 16 | 12.83 | 10.08 | 15.92 | 68,259 | 68,993 | 67,375 | 67,998 | |

Section Properties

Beam Type 3 -- 7" Web

| Section Area = | 420.9 | in2 |

| ||||||||||||||||

| Section = | 17.31 | in | |||||||||||||||||

| = | 66,991 | in4 | |||||||||||||||||

| Depth= | 39 | in | |||||||||||||||||

| Strand Size= | 0.6 | in | |||||||||||||||||

| = | 5 | ksi | |||||||||||||||||

| = | 7 | ksi |

| Cont. | Iinitial | Ifinal | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Span | # | T | H | S | e1 | e2 | e3 | A1 Bars 2-#5 |

A1 Bars 2-#6 |

A1 Bars 2-#5 |

A1 Bars 2-#6 |

| Group | 1 | 8 | 4 | 4 | 13.31 | 14.31 | 17.69 | 70,792 | 71,464 | 70,251 | 70,826 |

| I | 2 | 10 | 4 | 6 | 13.98 | 14.31 | 17.69 | 71,477 | 72,156 | 70,841 | 71,420 |

| 3 | 12 | 4 | 8 | 13.81 | 14.31 | 17.69 | 71,985 | 72,670 | 71,279 | 71,864 | |

| 4 | 14 | 6 | 8 | 13.81 | 13.31 | 16.69 | 72,326 | 73,016 | 71,575 | 72,163 | |

| 5 | 16 | 6 | 10 | 13.71 | 13.31 | 16.69 | 72,823 | 73,520 | 72,006 | 72,599 | |

| 6 | 18 | 8 | 10 | 13.71 | 12.31 | 15.69 | 73,006 | 73,707 | 72,166 | 72,762 | |

| 7 | 20 | 8 | 12 | 13.31 | 12.31 | 15.69 | 73,342 | 74,049 | 72,459 | 73,060 | |

| 8 | 22 | 8 | 14 | 12.74 | 12.31 | 15.69 | 73,532 | 74,242 | 72,626 | 73,229 | |

| 9 | 24 | 10 | 14 | 12.74 | 11.31 | 14.69 | 73,584 | 74,298 | 72,675 | 73,280 | |

| Group | 10 | 8 | 2 | 6 | 13.98 | 13.31 | 18.69 | 70,793 | 71,465 | 70,252 | 70,826 |

| II | 11 | 10 | 2 | 8 | 14.31 | 13.31 | 18.69 | 71,476 | 72,155 | 70,840 | 71,420 |

| 12 | 12 | 2 | 10 | 14.11 | 13.31 | 18.69 | 71,985 | 72,670 | 71,279 | 71,864 | |

| 13 | 14 | 4 | 10 | 13.71 | 14.31 | 17.69 | 72,487 | 73,178 | 71,714 | 72,303 | |

| 14 | 16 | 4 | 12 | 13.98 | 12.31 | 17.69 | 72,825 | 73,522 | 72,007 | 72,600 | |

| 15 | 18 | 6 | 12 | 13.98 | 11.31 | 16.69 | 73,007 | 73,708 | 72,167 | 72,764 | |

| 16 | 20 | 6 | 14 | 13.60 | 11.31 | 16.69 | 73,344 | 74,051 | 72,461 | 73,061 | |

| 17 | 22 | 6 | 16 | 13.06 | 11.31 | 16.69 | 73,531 | 74,242 | 72,625 | 73,229 | |

| 18 | 24 | 8 | 16 | 13.06 | 10.31 | 15.69 | 73,584 | 74,298 | 72,674 | 73,280 | |

Section Properties

Beam Type 3 -- 8" Web

| Section Area = | 459.9 | in2 |

| ||||||||||||||||

| Section = | 17.49 | in | |||||||||||||||||

| = | 72,106 | in4 | |||||||||||||||||

| Depth= | 39 | in | |||||||||||||||||

| Strand Size= | 0.60 | in | |||||||||||||||||

| = | 5 | ksi | |||||||||||||||||

| = | 7 | ksi |

| Cont. | Iinitial | Ifinal | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|