903.3 Ground-Mounted Sign Supports

903.3.1 Post-Mounted Sign Installation

Guidance. Signs should be post-mounted whenever possible unless mounting overhead is justified.

Standard. All post-mounted structural signs and sheet signs shall be mounted on pipe posts, wide flange (WF) fabricated steel posts, u-channel posts, perforated square steel tube posts or wood posts as shown in the standard plans.

| Forms |

| Signpost Selection Guide |

| Printable Signpost Selection Guide for use in the field |

Cross-sections of relocated or new signs shall be drawn and included in the final plans. The cross-sections are drawn to a scale of 1 in. = 5 ft. (1:50) to allow for scaling of quantities. Random grid lines shall be used to draw the cross-section and elevations are not shown. All cross-sections shall be drawn as the driver views the sign face. A note shall be added to the cross-section if the footing depth is greater than the minimum shown in the standard plans.

The following information shall be shown for each sign:

- Sign number

- Station

- Edge of traveled way

- Edge of shoulder

- Sign dimensions

- Guardrail and curb locations

- Post configuration

- All non-standard horizontal and vertical clearances

- Backing bars and post lengths

For multiple post designs, the posts shall be numbered from left to right, and only one post design type per sign shall be used.

Existing signs relocated to new posts and posts being used in place shall be shown with dashed lines.

All signs that are back-to-back shall be noted and the far sign shall be shown with dashed lines.

It is not necessary to outline the footing width and depth since this information is noted in the standard plans.

The post stub length shall be shown below the finished ground line in order to scale the correct post pay length.

Guidance. Utility and light poles should not to be used to mount signs, expect as mentioned below.

Option. In areas with space restrictions, available truss columns, signal poles, etc. may be used to mount sheet signs.

Support. See Standard Plan 903.03 for recommended footing depths for various post designs and slopes.

903.3.2 Lateral Offset (MUTCD Section 2A.19)

Standard. Post-mounted sign supports shall be crashworthy (breakaway, yielding or shielded with a longitudinal barrier or crash cushion) if within the clear zone.

Guidance. For post-mounted signs, the minimum lateral offset should be 12 ft. from the edge of the travelway. If an existing shoulder is wider than 6 ft., the minimum lateral offset for post-mounted signs should be 6 ft. from the edge of the shoulder or front face of curb.

Where existing signs are located within 6 ft. of a utility pole, they should be relocated to provide a minimum distance of 12 ft. where practical through normal sign replacement.

EXIT signs placed in the gore only require a 2 ft. lateral offset from both edges of shoulder or front face of curbs.

For divisional and channelizing islands, a 2 ft. lateral offset should be maintained between the edge of sign and the front face of curb. For islands with restricted width the sign should not extend beyond the curb. When signing at the nose of a 4 ft. median, a 1 ft. lateral offset is acceptable between the edge of sign and the front face of curb.

Maximum clearances will depend on roadway geometrics, profiles, and cross-sections, which all affect the visibility of the sign. Sheet type and structural type signs are generally to be placed no more than 15 ft. from the edge of shoulder.

New sign installations should be a minimum distance of 12 ft. from existing utility poles.

Support. The minimum lateral offset is intended to keep trucks and cars that use the shoulders from striking the signs or supports.

It is acceptable to adjust the standard lateral offset to obtain a better cross-section and still maintain sign effectiveness and visibility. For example, signposts are not placed in the center of ditches; therefore the lateral offset may be adjusted to better span a flat bottom ditch. Existing drainage structures, pull boxes and sidewalks may also affect lateral offset.

Lateral offset are not noted on Form D-29 unless they differ from the standard 6 ft. offset.

Guidance. All supports should be located as far as practical from the edge of the shoulder. Exposing traffic to sign supports should be minimized by placing signs in such locations as behind existing roadside barriers or on over-crossing structures.

A minimum sight distance of signs should be maintained. There should be a minimum of 60 ft. of sight distance for each inch of letter height with a 1000 ft. minimum for all mainline signs. Signs on conventional roads should have a minimum 250 ft. sight distance. Refer to Tables 903.6.5 and 903.6.6. When this is not possible, relocating or providing additional advance signing should be considered.

Option. Where permitted, signs may be placed on existing supports used for other purposes, such as highway traffic signal supports.

Standard. If signs are placed on existing supports, they shall meet other placement criteria contained in this article.

Option. Lesser lateral offsets may be used on connecting roadways or ramps at interchanges, but not less than 6 ft. from the edge of the travelway. In urban areas where it is impractical to locate a sign with the lateral offset prescribed by this article, a lateral offset of at least 2 ft. may be used. A lateral offset of at least 1 ft. from the face of the curb may be used in business, commercial or residential areas where sidewalk width is limited or where existing poles are close to the curb.

Guidance. Post-mounted sign supports should not intrude into the usable width of a sidewalk or other pedestrian facility.

Support. Figs. 903.2.26.1 and 903.2.26.2 illustrate some examples of the lateral offset requirements contained in this portion of the article.

It is acceptable to adjust the standard lateral offset to obtain a better cross-section and still maintain sign effectiveness and visibility. For example, signposts are not placed in the center of ditches, therefore the lateral offset may be adjusted to better span a flat bottom ditch. Existing drainage structures, pull boxes and sidewalks may also affect lateral offset.

903.3.3 Mounting Height (MUTCD Section 2A.18)

Standard. The provisions below shall apply unless specifically stated otherwise for a particular sign or object marker elsewhere in the EPG.

Mounting heights for single wide-flange and all post designs are set from the edge of travelway to the bottom of the lowest sign. Mounting heights for multiple wide-flange posts are set from the edge of travelway to the bottom of the lowest sign, or the length of the shortest post, whichever requirement provides the higher clearance. Mounting heights for different designs are shown in the standard plans.

Supports for sheet SH signs, such as regulatory, warning and route shield markers, are designed to provide a mounting height of 7 ft. 0 in.

All two- and three-post signs (any LOGO sign or sign with white legend on green, blue or brown sheeting) have a minimum 7 ft. 6 in. clearance from the edge of travelway. Also, the shortest post is a minimum of 7 ft. 9 in. above the ground line to the bottom of the lowest sign. This will provide sufficient post length to allow hinge plate installation, provide a 7 ft. 0 in. clearance for errant vehicle impacts, and a 6 in. field adjustment.

Due to wide-flange post limitations, large mounting heights of 25 ft. or more are avoided by either moving the sign or considering a truss-mounted sign.

All two- and three-wide flange post signs contain hinge plates as shown in the standard plans. On the shortest post a mounting height of 7 ft. 9 in. is maintained from ground line to the bottom of the lowest sign. This will allow sufficient length of post for a hinge point cut line 3 in. from the bottom of the lowest sign. Maintaining this clearance on the shortest post is critical for exit gore and other signs located between roadways and have high exposure to traffic.

The minimum height, measured vertically from the bottom of the sign to the elevation of the near edge of the pavement, of signs installed at the side of the road in rural areas shall be 5 feet.

The minimum height, measured vertically from the bottom of the sign to the top of the curb, or in the absence of curb, measured vertically from the bottom of the sign to the elevation of the near edge of the travelway, of signs installed at the side of the road where parking or pedestrian movements are likely to occur, or where the view of the sign might be obstructed, shall be 7 feet.

Option. The height to the bottom of a secondary sign mounted below another sign may be 1 ft. less than the height specified in this article.

Signs are placed 30 ft. or more from the edge of the travelway may be installed with a minimum height of 5 ft., measured vertically from the bottom of the sign to the elevation of the near edge of the pavement.

A route sign assembly consisting of a route sign and auxiliary signs (see Route Sign Assemblies) may be treated as a single sign for the purposes of this article.

All posts except structural posts should have a minimum clearance of 5 ft. above the driving surface with a minimum post length of 5 ft. above the ground.

The mounting height may be adjusted when supports are located near the edge of the right of way on a steep backslope to avoid the sometimes less desirable alternative of placing the sign closer to the roadway.

Support. Fig. 903.2.26.1 illustrates some examples of the mounting height requirements contained in this article.

903.3.4 Pipe Posts

Support. Steel pipe posts are used for sheet (SH) signs up to 30 ft2. Available pipe size inside diameters are 2-1/2 in., 3 in. and 4 inch. Post sizes are determined using the Signpost Selection Guide. A printable Signpost Selection Guide for use in the field is also available. It is recommended to provide a two-post design for sheet sign widths greater than 3 ft. 6 in. (other than diamonds or the 48 in. and 60 in. YIELD signs). The extreme width sign, W, is calculated as: W = (area of signs + area of exposed backing bars + area of post above bottom of sign)/(extreme height of sign). For additional information, consult the Signpost Selection Guide. A Pipe Quick Reference is also available for commonly used signs and assemblies encountered in the field.

It is desirable to keep posts out of the ditch flow line, when possible.

Breakaway assemblies are required on all pipe posts, regardless of location. Multi-direction assemblies are also required and are noted on Form D-29.

The standard plans show design data for computing the weights (masses) of pipe posts, along with data for computing footing quantities.

903.3.5 Wide Flange (WF) Posts

Support. WF posts are used for mounting signs larger than 30 ft2. The post design number is determined from Signpost Selection Guide when a sign is mounted alone or with an exit panel above the main sign. A printable Signpost Selection Guide for use in the field is also available. The extreme width sign, W, is calculated as: W = (area of signs + area of exposed backing bars + area of post above bottom of sign)/(extreme height of sign).

For post designs No. 3, No. 4, No.5 and No.6 having weights greater than 18 lbs/ft., posts shall be spaced at least 7 ft. apart. For post designs No. 1 and No. 2, posts may be spaced less than 7 ft. apart. Do not use three No. 1 or No. 2 posts with a sign width of less than 10 feet 6 inches.

In many cases, two designs are possible using a two- or three-post design chart. There are no special criteria for determining which of these two designs to use. Generally, signs from 6 to 17 ft. wide will be designed for two posts, while signs wider than 17 ft. requires three posts. It is desirable to keep posts out of the ditch flow line and median, when possible. This may be a deciding factor for a two-post or three-post design.

While pipe posts are cheaper, a single WF post can support side-by-side route marker assemblies. Normally a number one WF post design will support a side-by-side assembly. For larger two-post sign design combinations consult the Signpost Selection Guide. The next higher post design is used when in doubt.

Standard Plan 903.03 shows data needed for computing the weights (masses) of WF posts, along with data to compute footing quantities.

Breakaway assemblies are required on all WF posts, regardless of location and are noted on Form D-29.

903.3.6 U-Channel Posts

Support. Steel channel posts are authorized as an alternate to wood posts in accordance with the Signpost Selection Guide.

These supports are galvanized 3 lb. steel posts used primarily for installing sheet (SH) signs. Details of these posts are shown on Standard Plan 903.03.

These posts are paid for by linear foot. No additional payment is made for hardware. The number of posts to be used is based on the sign area for each installation and is determined using the Signpost Selection Guide. Breakaway assemblies are not required for steel channel posts.

Guidance. Use of these posts should be based on discussions with district Traffic.

Option. The steel channel posts may have an optional soil or stabilizer plate (¼ in. x 10 in. x 10 in.) secured to the lower portion of the post by a minimum of two 5/16 in. diameter sign bolts so that the final location of the plate on the driven post is approximately 6 in. below the ground surface. This plate may be required on posts driven into soils typically encountered in northern or southeast Missouri or river bottoms. A typical 14 ft. post is driven a minimum of 2.5 ft. into the ground with 7.25 ft. maximum from the ground to the bottom of the sign, with 3.5 ft. behind the sign.

Steel channel posts may be direct driven or installed by means of a stub.

Standard. Stubs, if used, shall be installed in accordance with Standard Plan 903.03

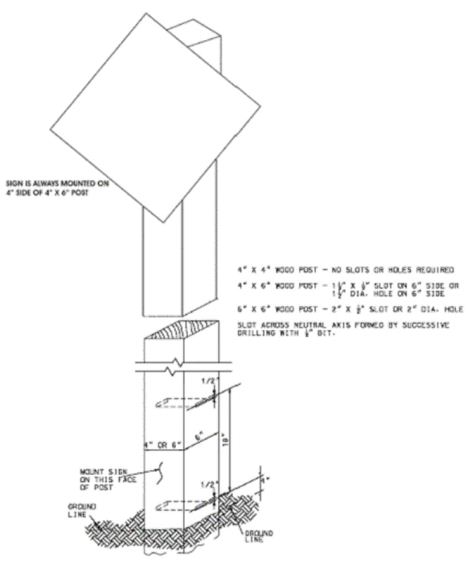

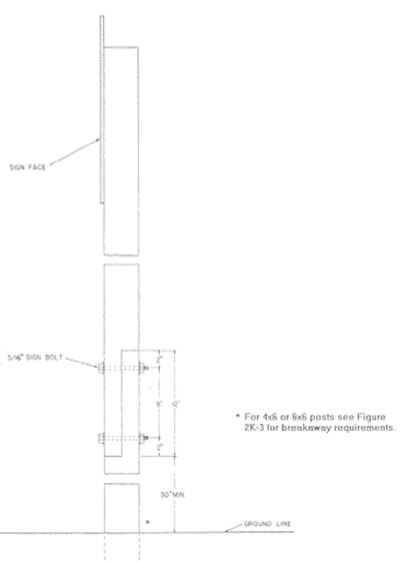

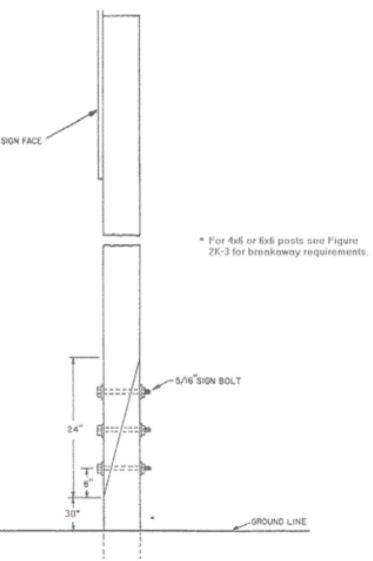

903.3.7 Wood Posts

Support. These supports are pressure treated 4 in. x 4 in., 4 in. x 6 in., or 6 in. x 6 in. wood posts used primarily for installing sheet (SH) signs. Details of these posts are shown on Standard Plan 903.03. These posts are paid for by the linear foot. No additional payment is made for slotting the larger posts or for hardware. The number of posts to be used is based on the sign area for each installation and is determined using the Signpost Selection Guide. A printable Signpost Selection Guide for use in the field is also available.

Standard. Signs shall be mounted on the 4 in. face side of the 4 in. x 6 in. wood post. Required drilling of these posts to create a breakaway system shall be performed according to Fig. 903.3.7.

Guidance. Use of these posts should be based on discussions with district Traffic.

In general, one-fourth of the length of a wood signpost should be in the ground. The minimum length of post in the ground should be 30 in. to ensure a stable installation.

Splicing Wood Posts

Standard. The district shall retain salvageable broken wood signposts for recycling.

Support. Three methods have been established for the purpose of splicing these posts. Figs. 903.3.7.1 and 903.3.7.2 represent the two methods for splicing posts both in the field and in the shop. Fig. 903.3.7.1 represents the most feasible and economical method used for splicing posts in the field. Fig. 903.3.7.2 depicts splices that can be performed in the shop or field as dictated by conditions and equipment.

Guidance. For the method as shown in Fig. 903.3.7.1, the splice should be located as near the top of the post as possible (minimum of 30 in. above the ground line) and the sign mounted on the post perpendicular to the "Z" shaped cut; that is, with the sign face perpendicular to the splicing bolts.

903.3.8 Perforated Square Steel Tube Posts

Support. Perforated Square Steel Tube (PSST) is authorized as an alternate to wood posts in accordance with the Signpost Selection Guide. These supports are galvanized 2 in. or 2.5 in. square 12-gauge steel posts used primarily for installing sheet (SH) signs. Details of these posts are shown on Standard Plan 903.03.

These posts are paid for by the linear foot, for each post used. An additional bid item must be included for the anchor sleeve for each post used and are also paid for by the linear foot. No additional payment will be made for hardware.

The number of posts to be used is based on the sign area for each installation and is determined using the Signpost Selection Guide. A printable Signpost Selection Guide for use in the field and a PSST Quick Reference Guide for commonly used signs and assemblies encountered in the field is also available.

PSST posts work well in paved areas where replacement of conventional signs posts is difficult and time-consuming and where frequent knockdowns occur. An island at an urban intersection would be an example of this, where the concrete surfacing prevents easy sign replacement and where accident damage is frequent.

Breakaway devices are not required for PSST posts unless required by Signpost Selection Guide.

Option. PSST posts may be direct-driven or installed by means of a sleeve that is first installed and then the post inserted and attached to the sleeve by means of a corner bolt.

Guidance. Use of these posts should be based on discussions with district Traffic.

903.3.9 Secondary Sign Supports

Support. These supports are aluminum wide-flange posts used to attach service signs and exit number panels to structural signs. Details of these posts are shown in the standard plans. There is no direct bid for these posts.

903.3.10 Backing Bars

Support. Backing bars support wide SH signs and side-by-side route assemblies. The standard plans show requirements for backing. Lengths and the weight per foot of backing bars are shown in the standard plans. Backing bars are totaled and included in the bid item for structural steel posts. Backing bars are totaled on Form D-29. If there is no structural steel posts, then the backing bars are included in the bid item for pipe posts.

903.3.11 Hinge Plates

Support. Hinge plates are installed on all WF post designs as shown in the standard plans. Hinge plate cut lines are 3 in. below the bottom of the lowest sign. The cut line is a minimum of 7 ft. 6 in. above the ground line on the shortest post. No direct pay is made for hinge plates.

903.3.12 Breakaway Assemblies

Standard. All signposts shall be an approved breakaway assemblies design. All sign supports used shall be in compliance with this article or the Standard Plans. Breakaway assemblies shall not be required for U-channel or wood posts.

Sign trusses and other large sign support structures that are not breakaway shall be shielded.

Support. Breakaway assemblies are totaled on Form D-29. All assemblies are paid for with the same bid item.

Guidance. The Signpost Selection Guide should be used to determine a breakaway assembly, the correct size and number of posts for installing signs.

Option. For perforated square steel tube posts, a breakaway design may or may not be required depending on the configuration of the posts. The Signpost Selection Guide should be referenced to make an appropriate determination. Damaged breakaway signposts may be made into signpost stubs. This can be accomplished by cutting the post to the proper stub length, inverting it and using it as a stub in lieu of purchasing new stubs.

903.3.13 Orientation (MUTCD Section 2A.20)

Support. The brightness of the sign may drop 24 percent when the normal lateral offset from edge of travelway is increased to 30 feet. The legibility remains at an 80 percent level or higher when using the standard 6 ft. lateral offset. The skew angle shown on the standard plans is valid for signs on tangent sections of road regardless of lateral offset distance. The skew angle may be adjusted to maintain brightness and avoid glare for signs on curved sections of road. The plans indicate which signs require a skew angle other than that shown in the standard plans.

Guidance. Unless otherwise provided in the EPG, signs should be vertically mounted at right angles to the direction of, and facing, the traffic that they are intended to serve.

Where mirror reflection from the sign face is encountered to such a degree as to reduce legibility, the sign should be turned slightly away from the road. Signs that are placed 30 ft. or more from the pavement edge should be turned toward the road. On curved alignments, the angle of placement should be determined by the direction of approaching traffic rather than by the roadway edge at the point where the sign is located.

Option. The standard skew angle is 93 degrees. However, skew angle may be adjusted to maintain brightness and avoid glare for signs on curved sections of road. On grades, sign faces may be tilted forward or back from vertical position to improve the viewing angle.

903.3.14 Sign Identification Decal

Standard. Every MoDOT sign, regardless of the type or style, shall have an Identification Decal on the sign. At the time of installation of the new sign, the year and month shall be indicated by the district.

Support. The Sign Production Center is placing these Identification Decals on the front side in the lower right hand corner of the sign.

903.3.15 Post and Mountings (MUTCD Section 2A.21)

Standard. Signposts, foundations, and mountings shall be so constructed as to hold signs in a proper and permanent position, and to resist swaying in the wind or displacement by vandalism.

Plastic/nylon washers shall be used between the heads of all twist fasteners (such as screws, bolts or nuts) and the sign sheeting to protect the sheeting from the twisting action of the bolt heads. Plastic/nylon washers are available through the Sign Production Center for districts.

Support. The latest edition of AASHTO’s Specifications for Structural Supports for Highway Signs, Luminaires, and Traffic Signals contains additional information regarding posts and mounting.

Option. Where engineering judgment indicates a need to draw attention to the sign during nighttime conditions, a strip of retroreflective material may be used on regulatory and warning sign supports.

Standard. If a strip of retroreflective material is used on the sign support, it shall be at least 2 in. wide, it shall be placed for the full length of the support from the sign to within 2 ft. above the edge of the roadway, and its color shall match the background color of the sign, except that the color of the strip for the YIELD and DO NOT ENTER signs shall be red.

903.3.16 Ordering Signs

Support. Standard signs are those signs, which are described in EPG 903. They have been defined for size and message and given a specific sign number. Standard signs are typically made of a single piece of flat aluminum. Examples of standard signs are STOP signs, YIELD signs, SPEED LIMIT signs and alignment signs.

Structural signs are those signs that are constructed using extruded aluminum panels. These signs are typically erected on steel breakaway posts or on overhead trusses. Structural signs are typically found on the interstate, freeway and expressway systems. Typical structural signs are EXIT signs (E5-1) and the EXIT DIRECTION signs (E4-1) found on freeways.

Roll-up signs are signs that are made on a flexible, reflective material. They are primarily used for short-term traffic control signs for maintenance operations.

Signs not listed in this article are considered special signs.

When ordering signs, there are several optional features available. These features are primarily related to vandalism control and are the following:

Protective Film: It is our intent to provide a system that will allow for the cleaning and removal of graffiti, dust and pollution from the sign surface. A protective overlay film is durable, solvent resistant and completely transparent. At this time, the cost to apply this film to all signs is prohibitive. If the district has certain locations that require sign replacement due to paint or graffiti, this film will allow the sign to be cleaned instead of replaced. Contact the Sign Production Center (SPC) for information on the cost and benefits of the protective film.

Plastic Signs: In areas where there is a problem with theft of aluminum signs, it is possible to make standard post-mounted signs on a plastic blank.

Standard. A requisition shall be submitted when ordering signs. General Services form E-82 shall be completed with the quantity, sign number, size and description indicated for each sign ordered. If the sign is needed on a rush or priority basis, this should be clearly indicated on the requisition.

An electronic requisition for structural signs shall be accompanied with detailed drawings of the required signs each on a separate page. Information for these signs shall include sign legend and roadway type. It shall also include on the requisition whether the signs are shoulder-mounted or overhead-mounted signs. If the signs have any pre-existing size restrictions, this shall also be noted on the requisition. If the district requires knowledge of the exact size of signs prior to fabrication, this shall be noted on the requisition.

Traffic shall approve all requisitions for special signs before fabrication. Special signs shall be on a separate requisition from in order to reduce delay in shipping, other sign types while the special sign is being reviewed. If a special sign is required, a description of the sign including color information, the sign's proposed location, and the reason for its use should be forwarded to Traffic for approval.

At the time of manufacturing, a detailed drawing of these special signs shall be forwarded to the district. The SPC will produce annually a listing of approved special sign numbers and legends.

Guidance. If the structural sign is a replacement for an existing sign, dimensions of the existing sign should be provided if possible. After fabrication a detailed drawing of the sign should be forwarded to the district sign shop that should be retained for future reference.

General Services orders roll up signs on a yearly basis. A requisition is to be submitted by the district.

If either of the two vandalism control features is needed on a sign it should be clearly indicated on the sign requisition.

The SPC will ship the sign order to the district, and upon receipt of a sign order, the district should inspect the signs for damage and to verify the quantities, types and legends of the signs. If problems with the order are found, the district should notify the SPC of the problems.

Option. The special sign request may include a sketch of the proposed sign and/or a picture of the problem location. A plan for evaluating the effectiveness of the special sign may be requested by Traffic.

903.3.17 Ordering Posts

Support. Table 903.3.17 contains information on posts.

When ordering pipe posts and stubs, note the size is the inside diameter. When ordering clamps and caps the size is the outside diameter.

Each district is to maintain a supply of signposts, based on average annual usage, for each type of post.

Table 903.3.17 Posts

| Post Type | Commodity Code | Description |

|---|---|---|

| U-Channel | 8013047500 | POST, MEDIUM CHANNEL, #2, 6' |

| 8013047505 | POST, MEDIUM CHANNEL, #2, 6'6" | |

| 8013047510 | POST, MEDIUM CHANNEL, #2, 8' | |

| 8013047515 | POST, MEDIUM CHANNEL, #2, 9' | |

| 8013047520 | POST, MEDIUM CHANNEL, #2, 10' | |

| 8013047525 | POST, MEDIUM CHANNEL, #2, 12' | |

| 8013047527 | POST, MEDIUM CHANNEL, #2, 14' | |

| 8013047528 | POST, MEDIUM CHANNEL, #2, 15' | |

| 8013047529 | POST, MEDIUM CHANNEL, #2, 16' | |

| 8013047530 | POST, HEAVY CHANNEL, #3, 6' | |

| 8013047535 | POST, HEAVY CHANNEL, #3, 9' | |

| 8013047540 | POST, HEAVY CHANNEL, #3, 10' | |

| 8013047545 | POST, HEAVY CHANNEL, #3, 12' | |

| 8013047550 | POST, HEAVY CHANNEL, #3, 14' | |

| 8013055700 | POST, SIGN, STEEL, R/W POST, 6 FT. 1 LB, STEEL CHANNEL | |

| 8013055720 | POST, SIGN, STEEL, DELINEATOR POST, 7FT. STEEL CHANNEL | |

| Pipe | 8013047137 | POST, SIGN, PIPE, 2-1/2 IN (I.D.) X 10 FT. |

| 8013047139 | POST, SIGN, PIPE, 2-1/2 IN (I.D.) X 12 FT | |

| 8013047141 | POST, SIGN, PIPE, 2-1/2 IN (I.D.) X 14 FT. | |

| 8013047143 | POST, SIGN, PIPE, 2-1/2 IN (I.D.) X 16 FT. | |

| 8013047145 | POST, SIGN, PIPE, 2-1/2 IN (I.D.) X 18 FT. | |

| 8013047147 | POST, SIGN, PIPE, 2-1/2 IN (I.D.) X 20 FT. | |

| 8013047171 | POST, SIGN, PIPE, 3 IN (I.D.) X 10 FT. | |

| 8013047172 | POST, SIGN, PIPE, 3 IN (I.D.) X 12 FT. | |

| 8013047174 | POST, SIGN, PIPE, 3 IN (I.D.) X 14 FT. | |

| 8013047176 | POST, SIGN, PIPE, 3 IN (I.D.) X 16 FT. | |

| 8013047178 | POST, SIGN, PIPE, 3 IN (I.D.) X 18 FT | |

| 8013047180 | POST, SIGN, PIPE, 3 IN (I.D.) X 20 FT. | |

| 8013047212 | POST, SIGN, PIPE, 4 IN (I.D.) X 12 FT. | |

| 8013047214 | POST, SIGN, PIPE, 4 IN (I.D.) X 14 FT. | |

| 8013047216 | POST, SIGN, PIPE, 4 IN (I.D.) X 16 FT. | |

| 8013047218 | POST, SIGN, PIPE, 4 IN (I.D.) X 18 FT. | |

| 8013047220 | POST, SIGN, PIPE, 4 IN (I.D.) X 20 FT. | |

| 8013023252 | STUB, SIGN, PIPE, 2-1/2 IN (I.D.) X 4 FT - 3-1/2 IN | |

| 8013023254 | STUB, SIGN, PIPE, 3 IN (I.D.) X 4 FT - 3-1/2 IN | |

| 8013023258 | STUB, SIGN, PIPE, 4 IN (I.D.) X 5 FT - 3-1/2 IN | |

| 8010120294 | BREAKAWAY HARDWARE, SIGN, PIPE, 2-1/2 IN (I.D.) & 3 IN (I.D.) | |

| 8010120296 | BREAKAWAY HARDWARE, SIGN, PIPE, 4 IN (I.D.) | |

| Structural/Wide Flange (WF) | 8013047412 | POST, SIGN, STRUCTURAL DESIGN #1, W6 X 9 - 12' 0 |

| 8013047414 | POST, SIGN, STRUCTURAL DESIGN #1, W6 X 9 - 14' 0 | |

| 8013047416 | POST, SIGN, STRUCTURAL DESIGN #1, W6 X 9 - 15' 0 | |

| 8013047418 | POST, SIGN, STRUCTURAL DESIGN #1, W6 X 9 - 16' 0 | |

| 8013047420 | POST, SIGN, STRUCTURAL DESIGN #1, W6 X 9 - 18' 0 | |

| 8013047422 | POST, SIGN, STRUCTURAL DESIGN #1, W6 X 9 - 20' 0 | |

| 8013047424 | POST, SIGN, STRUCTURAL DESIGN #1, W6 X 9 - 30' 0 | |

| 8013047884 | POST, SIGN, STRUCTURAL DESIGN #2, W6 X 15 - 14' 0 | |

| 8013047886 | POST, SIGN, STRUCTURAL DESIGN #2, W6 X 15 - 15' 0 | |

| 8013047888 | POST, SIGN, STRUCTURAL DESIGN #2, W6 X 15 - 16' 0 | |

| 8013047890 | POST, SIGN, STRUCTURAL DESIGN #2, W6 X 15 - 17' 0 | |

| 8013047906 | POST, SIGN, STRUCTURAL DESIGN #2, W6 X 15 - 18' 0 | |

| 8013047908 | POST, SIGN, STRUCTURAL DESIGN #2, W6 X 15 - 20' 0 | |

| 8013047439 | POST, SIGN, STRUCTURAL DESIGN #2, W6 X 15 - 30' 0 | |

| 8013047909 | POST, SIGN, STRUCTURAL DESIGN #3, W8 X 18 - 18' 0 | |

| 8013047910 | POST, SIGN, STRUCTURAL DESIGN #3, W8 X 18 - 20' 0 | |

| 8013047911 | POST, SIGN, STRUCTURAL DESIGN #3, W8 X 18 - 22' 0 | |

| 8013047934 | POST, SIGN, STRUCTURAL DESIGN #3, W8 X 18 - 24' 0 | |

| 8013047936 | POST, SIGN, STRUCTURAL DESIGN #3, W8 X 18 - 26' 0 | |

| 8013047940 | POST, SIGN, STRUCTURAL DESIGN #3, W8 X 18 - 30' 0 | |

| 8013047912 | POST, SIGN, STRUCTURAL DESIGN #4, W10 X 22 - 28' 0 | |

| 8013047923 | POST, SIGN, STRUCTURAL DESIGN #4, W10 X 22 - 18' 0 | |

| 8013047924 | POST, SIGN, STRUCTURAL DESIGN #4, W10 X 22 - 20' 0 | |

| 8013047925 | POST, SIGN, STRUCTURAL DESIGN #4, W10 X 22 - 22' 0 | |

| 8013047926 | POST, SIGN, STRUCTURAL DESIGN #4, W10 X 22 - 26' 0 | |

| 8013047927 | POST, SIGN, STRUCTURAL DESIGN #4, W10 X 22 - 24' 0 | |

| 8013047929 | POST, SIGN, STRUCTURAL DESIGN #4, W10 X 22 - 30' 0 | |

| 8013047913 | POST, SIGN, STRUCTURAL DESIGN #5, W10 X 26 - 25' 0 | |

| 8013047914 | POST, SIGN, STRUCTURAL DESIGN #5, W10 X 26 - 40' 0 | |

| 8013047915 | POST, SIGN, STRUCTURAL DESIGN #5, W10 X 26 - 30' 0 | |

| 8010120255 | POST, SIGN, STRUCTURAL DESIGN #6, W12 X 35 - 40' 0 | |

| 8013023388 | STUB, SIGN, STRUCTURAL DESIGN #1, W6 X 9 - 3' 0 | |

| 8013023396 | STUB, SIGN, STRUCTURAL DESIGN #2, W6 X 15 - 4' 0 | |

| 8013023416 | STUB, SIGN, STRUCTURAL DESIGN #3, W8 X 18 - 4' 6 | |

| 8013023426 | STUB, SIGN, STRUCTURAL DESIGN #4, W10 X 22 - 5' 0 | |

| 8013023436 | STUB, SIGN, STRUCTURAL DESIGN #5, W10 X 26 - 5' 0 | |

| 8010120250 | STUB, SIGN, STRUCTURAL DESIGN #6, W12 X 35 - 5' 6 | |

| 8010120260 | FUSE PLATE, SIGN, STRUCTURAL DESIGN #1 | |

| 8010120262 | FUSE PLATE, SIGN, STRUCTURAL DESIGN #2 | |

| 8010120264 | FUSE PLATE, SIGN, STRUCTURAL DESIGN #3 | |

| 8010120266 | FUSE PLATE, SIGN, STRUCTURAL DESIGN #4 | |

| 8010120268 | FUSE PLATE, SIGN, STRUCTURAL DESIGN #5 | |

| 8010120270 | FUSE PLATE, SIGN, STRUCTURAL DESIGN #6 | |

| 8010120275 | SPLICE PLATE, SIGN, STRUCTURAL DESIGN #1 | |

| 8010120277 | SPLICE PLATE, SIGN, STRUCTURAL DESIGN #2 | |

| 8010120279 | SPLICE PLATE, SIGN, STRUCTURAL DESIGN #3 | |

| 8010120281 | SPLICE PLATE, SIGN, STRUCTURAL DESIGN #4 | |

| 8010120283 | SPLICE PLATE, SIGN, STRUCTURAL DESIGN #5 | |

| 8010120285 | SPLICE PLATE, SIGN, STRUCTURAL DESIGN #6 | |

| 8010120290 | BREAKAWAY HARDWARE, SIGN, STRUCTURAL DESIGN #1, #2, #3 | |

| 8010120292 | BREAKAWAY HARDWARE, SIGN, STRUCTURAL DESIGN #4, #5, #6 | |

| PSST | 8013047570 | POST, SQUARE, PERFORATED, 2"X10' |

| 8013047620 | POST, SQUARE, PERFORATED, 2" X 12' | |

| 8013047670 | POST, SQUARE, PERFORATED, 2" X 14' | |

| 8013047672 | POST, SQUARE, PERFORATED, 2" X 16' | |

| 8013047575 | POST, SQUARE, PERFORATED, 2.5"X10' | |

| 8013047625 | POST, SQUARE, PERFORATED, 2.5" X 12' | |

| 8013047675 | POST, SQUARE, PERFORATED, 2.5" X 14' | |

| 8013047679 | POST, SQUARE, PERFORATED, 2.5" X 16' | |

| 8010120305 | POST, DOUBLER, SQUARE, PERFORATED, 2.25” X 6’, 12 GAUGE | |

| 8013047685 | SPLICE, SQUARE, PERFORATED, 1.75"X1' | |

| 8013023206 | ANCHOR, SQUARE, PERFORATED, 2.25"X 3', 12 GAUGE | |

| 8013023208 | ANCHOR, SQUARE, PERFORATED, OMNI DIRECTIONAL, 2.25" X 3', 12 GAUGE | |

| 8013023214 | ANCHOR, HEAVY DUTY, 2.5" x 3', 7 GAUGE | |

| 8013023210 | ANCHOR, HEAVY DUTY, OMNI DIRECTINAL 2.5" x 3', 7 GAUGE | |

| 8010120300 | ANCHOR, HEAVY DUTY, 2.5" x 4', 7 GAUGE | |

| 8013059083 | BOLT, ANCHOR, CORNER 5/16" X 2" ZINC GALVANIZED, GRADE 2 W/NUT MEDIUM | |

| 8013047689 | SPLICE, SQUARE, PERFORATED, 2.25"X 1', 12 GAUGE | |

| 8013023230 | ANCHOR, HEAVY DUTY, 3" X 3', 7 GAUGE | |

| 8010120302 | ANCHOR, HEAVY DUTY, 3" X 4', 7 GAUGE | |

| 8013023211 | ANCHOR, HEAVY DUTY, OMNI DIRECTIONAL, 3" X 3', 7 GAUGE | |

| 8013059085 | BOLT, ANCHOR, CORNER 5/16" X 2 .5" ZINC GALVANIZED, GRADE 2 W/NUT LARGE | |

| 8013059100 | BOLT, ANCHOR, SHOULDER 3/8" X 3.5" ZINC GALVANIZED, GRADE 2 W/NUT (USED FOR ALL HEAVY-DUTY ANCHORS) |

903.3.18 Post Storage

Standard. Wood posts shall not be painted.

Guidance. Wood posts should be stacked properly to prevent warping, including bands remaining on the posts until they should be used. Steel posts should be stored so that they do not lie on the ground. Steel posts, if galvanizing becomes chipped or otherwise damaged, are not to be painted with a liquid galvanizing paint.

903.3.19 Project Contract Signing Field Checks

Support. It is suggested that district traffic personnel, in conjunction with construction and/or design personnel, conduct field checks of project contract signing as soon as the roadway has been roughed-in to the extent that the actual visibility and effectiveness of each sign can be determined.

903.3.20 Maintenance (MUTCD Section 2A.22)

Support. The storing methods are in place to prevent damage to the sign sheeting. Storing signs wet or horizontally will damage the retroreflective elements of the sheeting. MoDOT has a warranty for the sign sheeting, but improper storage will void the warranty.

Standard. If packaged signs become wet, they shall be unpacked immediately and allowed to dry. Signs shall always be stored indoors on edge. New signs shall be stored in a cool, dry area to prevent moisture damage.

Guidance. All traffic signs should be kept properly positioned, clean, and legible, and should have adequate retroreflectivity. Damaged or deteriorated signs should be replaced.

To assure adequate maintenance, a schedule for inspecting (both day and night) and replacing signs should be established. All employees whose duties require that they travel on the roadways should be encouraged to report any damaged, deteriorated, or obscured signs at the first opportunity.

Weeds, trees, shrubbery, and construction, maintenance and utility materials and equipment should not obscure the face of any sign.

|

|

903.3.21 Sign Inspection and Inventory

Standard. A sign maintenance program shall be established for all routes within our systems. All signs on all routes shall be inspected once a year as follows:

A. Even numbered years a daylight inspection shall be performed.

B. Odd numbered years a night inspection shall be performed.

District database information containing sign logs for interstate, primary and supplementary systems shall be submitted to Maintenance office by July 1 of each year. It is the intention for this Division office to retain only the current year's sign logs. Each district shall retain copies of previous sign logs. The sign logs sent to the Traffic Division as required by the due date list shall be copies of each district's sign logs with the district retaining the master and a backup.

Guidance. Appropriate district personnel should perform the inspection of the interstate and primary systems. The sign inventory process is typically:

A. The sign inspection log shall include every sign on all routes within our system.

B. The exact message of those signs classified as guide signs shall be provided on the sign inspection log with no abbreviations.

C. Signs other than guide signs may be abbreviated. Care should be used in abbreviations that there will be no misunderstanding as to their meaning.

D. For those signs within an assembly, such as a junction assembly, the log should reflect the total number of signs within that assembly.

E. Trailblazer signs for LOGO signs should be logged using the corresponding generic service panel (i.e.: Gas LOGO D9-7G, Food LOGO D9-7F, Lodging LOGO D9-7L, Camping LOGO D9-3, Attractions LOGO D9-7a).

F. Signs requiring maintenance should be noted on the log.

Sign inspections should be performed and recorded as follows:

A. All signs should be logged if the sign’s face is visible for that direction of travel.

B. When a sign on an intersecting road with our system is logged, the other system should be identified.

- 1. If possible, identify the county road or city street by name and also note whether the intersecting road is a crossroad or on the right or left.

- 2. This data can be noted in parenthesis in the comments section.

- 3. Other items which should be noted in the comments section are whether the signs are mounted back-to-back and/or at 90 degrees to another sign.

C. Slashes should be used to differentiate between lines on a sign.

D. Arrows should be recorded as follows AH (ahead), LT (left), RT (right), 45LT and 45RT.

E. Routes must be designated with a prefix in order to efficiently sort the file.

- 1. The designation of "IS" will be used for Interstate Routes, "US" for U.S. Routes, "MO" for Missouri lettered and numbered routes and “BU” for Business Routes.

- 2. Lettered prefixes will immediately precede the route designation with no space or dash between the designation and the route.

- 3. When the route is a business or spur route, no designation will be necessary.

F. Signs within an assembly should be numbered from top to bottom and the columns will be lettered from left to right with the first column having no letter, the second column having letter "A" and so on. (See Fig. 903.3.21 Standard Numbering for Route Marker Assemblies)

G. The log mile used to record the location of a sign should be the same as the log mile system established for accident data.

It is recommended an individual should be trained for proper mounting location and sign height, as well as inventory and sign ordering procedures. This individual would check to see that items marked on sign logs are accomplished within the year. The number of individuals trained in signing is based on district needs.

Sign quantities should be indicated by commodity code for each sign number within each organization. This is imperative to enable the inventory to be correctly maintained.

Support. The maximum inventory levels for all signs have been determined from the average annual usage for each type of sign. The maximum inventory represents approximately 1/3 of the average annual usage. This policy does not apply to signs used for emergency closures and routine maintenance operation traffic control signs.

The route designations used during the log process allow the records to be sorted by route without sorting out additional routes. For example, when sorting Route 3 without the designation prior to the number, one would also access Routes 35, 350 etc.

Examples of the lettered prefixes for route designations are shown in Table 903.3.21.

Table 903.3.21 Route Designations

| Word Message | Standard Abbreviation |

|---|---|

| Interstate | IS |

| US Numbered Route | US |

| Missouri Numbered Route | MO |

| Alternate Route | AL |

| Missouri Letter Route | RT |

| Business Loop (Interstate Only) | LP |

| Business Route | BU |

| Spur Route | SP |

| Reversible Route | RV |

| Outer Road | OR |

| City Street | CST |

| County Road | CRD |

| Ramp | RP |

| Connector for Wye Leg | CO |

| Rest Area | RA |

| Weight Station | WS |

| National Forest Service | NFS |

| National Park Service | NPS |

| Fish Wildlife Service | FWS |

| Corp of Engineers | COE |

| Department of Defense | DOD |

| Alley | ALY |

| Private Road | PVT |

| Railroad | RR |

| Pedestrian Path | PED |

| Park Trail | PK |

When the route is a business or spur route, no designation will be necessary. The nomenclature is provided in Table 903.3.21.

903.3.22 Salvaged Signs

Standard. All damaged aluminum signs, except for those that are severely mangled or bent, should be kept for reclamation. All aluminum signs that are reclaimable shall be delivered to:

- Moberly Correctional Facility

- 5201 South Morley

- Moberly, MO 65270

All steel signs shall be kept at the district and sold as scrap by the district. Before a steel sign is sold for scrap the sign face shall be defaced so that the sign can no longer be used.

Guidance. Signs should be delivered on normal workdays between the hours of 8:00 a.m. and 2:30 p.m. One day's notice of delivery should be given by calling the institution's clerk at (660) 263-3778, Ext. 442.

Support. All signs are the property of the Commission with the exception of TODS and signs installed by others. Proper procedures need to be followed for disposing and defacing of old, faded or damaged signs. We are not allowed to sell signs.

The Moberly Correctional Facility does not require signs to be banded or on pallets.

There are several available options of hauling these reclaimable signs to the Moberly facility. One option is to use district resources to haul these signs. Another option is to use the current contract carrier who is hauling signs to your location from the sign shop; or if General Services is hauling to your location you may use them.

The last two options of delivery systems will have certain restrictions for hauling of this product. Contact the service provider to ensure that you meet the requirements.

903.3.23 Response to Emergencies

Support. Risk Management has established guidelines concerning the response to replacing signs that have been knocked down or otherwise lost, see Table 903.3.23.

Guidance. The Risk Management Manual should be consulted for the proper procedures to follow.

Support. Priority ranking are defined as follows:

- Priority 1 – Urgent, respond as soon as possible (day or night, weekends or holidays) suspending other lower priority work if necessary. May represent immediate hazard to the public.

- Priority 2 – Repair should be accomplished as soon as practical during normal working hours, but only after Priority 1 repairs are completed.

- Priority 3 – Repair should be accomplished with higher urgency than routine maintenance.

- Priority 4 – Not urgent, normally considered routine maintenance.

Table 903.3.23 Incident Response Signing Plan

| Signs | Priority | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Barricades (permanent) | - | X | - | - |

| Delineators | - | - | - | X |

| Freeway/Expressway1 | - | X | - | - |

| Guide1 | - | - | X | - |

| Information1 | - | - | X | - |

| Regulatory1 | Critical (i.e. Stop, Yield, Do Not Enter, Wrong Way, One Way) | All others | - | - |

| Warning1 | - | X | - | - |

| School1 | - | - | X | - |

| Visibility (weeds, trees, etc.) | Involving Regulatory Signs or Signals | All others | - | - |

| Sign Lighting | - | - | X | - |

| Sign Truss Structure Damage | Creating a Traffic Hazard | - | Not A Traffic Hazard | - |

| Lane Closure Notification/ Approval Required2 | No | No | Yes | Yes |

| Note: Priorities are guidelines and may be upgraded if deemed necessary | ||||

| 1 Damage that makes the sign ineffective. | ||||

| 2 NHS routes and all other routes with AADT of 1,700 or greater. | ||||

903.3.24 Median Opening Treatments for Divided Highways with Wide Medians (MUTCD Section 2A.23)

Guidance. Where divided highways are separated by median widths at the median opening itself of 30 ft. or more, median openings should be signed as two separate intersections.