751.39 Pile Footings: Difference between revisions

m Bridge has updated this article to show the correct design method (previous method was incorrect). |

m Per Bridge, much of the article was updated to conform with LRFD practices. |

||

| Line 1: | Line 1: | ||

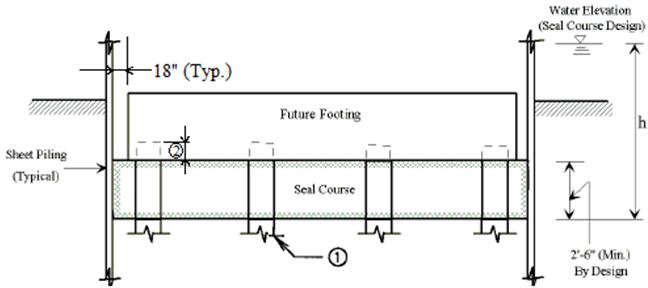

[[Image:751.39 seal course. | [[Image:751.39 seal course.jpg|right|thumb|700px|<center>'''Notes:''' <br>''' 1)''' All pile shall be vertical. <br> | ||

'''2)''' For AASHTO Guide Specification for LRFD, <br> | |||

12” for seismic design category A and 18” for seismic design category B, C and D.</center> ]] | |||

== | |||

==751.39.1 General Requirements== | |||

Water elevation is to be determined for the site conditions by the preliminary design section; generally, less than the average of high and low water. | Water elevation is to be determined for the site conditions by the preliminary design section; generally, less than the average of high and low water. | ||

Determine the uplift | Determine the factored uplift load per pile by deducting the weight of the seal course and friction between seal course and sheet piling of cofferdam from the uplift force produced by the hydrostatic head "h". | ||

Use a friction value between the seal course and the sheet piling of 2 lbs./in<sup>2</sup> acting on (perimeter x depth) of seal course. | Use a friction value between the seal course and the sheet piling of 2 lbs./in<sup>2</sup> acting on (perimeter x depth) of seal course. | ||

===Pile Pull-out Force== | Factored uplift load per pile = | ||

:Load factor for uplift x (Uplift force of water – Weight of seal course – Friction between seal course & sheet piling) / No. of piles | |||

==751.39.2 Pile Pull-out Force== | |||

Maximum factored resistance per pile shall be determined by the minimum of: | |||

:(1) Factored resistance for skin friction = Geotechnical resistance factor for skin friction x Nominal skin friction resistance | |||

: | ::Use "DRIVEN" program to calculate nominal skin friction resistance of pile (without tip resistance). | ||

: | ::Geotechnical resistance factor for skin friction, φ<sub>up</sub>. from LRFD Table 10.5.5.2.3-1 | ||

:( | ::Use φ<sub>up</sub> = 0.2 from LRFD table 10.5.5.2.3.-1 for single pile unless higher resistance factor can be justified based on soil type and test method. | ||

:(2) Factored resistance for pile tension = Structural resistance factor for pile tension x Yield strength of steel x Steel area of pile. | |||

Note: | ::Note: Since CIP pile is not filled at this stage, use steel pipe pile area without concrete to determine the factored resistance for pile tension. ASTM 252 allows “the wall thickness at any point shall not be more than 12.5% under the specified nominal wall thickness. For steel pipe pile area computation consider 87.5% of wall thickness. | ||

::Structural resistance factor for pile tension, φ<sub>y</sub> = 0.25 | |||

:(3) Factored resistance for 10 psi adhesion = structural resistance factor for 10 psi adhesion x 10 psi x Pile perimeter x Depth of seal course | |||

::Structural resistance for 10 psi pile adhesion, Φ<sub>3</sub> = 1.0 | |||

::For HP pile perimeter use 2*(Depth + Width) of HP shape. | |||

'''Plan Reporting''' | |||

Seal Course size shall be shown on the plans as designed. | |||

Seal Courses are typically designed for one footing only. They may be designed for uplift loads developed under more than one footing or where there is economy of scale in constructing a larger cofferdam, for example: | |||

:(1) where individual seal courses are proximate and costlier than considering one large seal course under more than one footing, and | |||

:(2) where removal of an existing footing requires a larger cofferdam to be constructed enclosing both existing and new locations of footings with the result that a larger than usual seal course size may be less costlier than individually constructed cofferdams. | |||

Where a seal course is to be designed to resist the uplift loads resulting from the proposed construction of more than one footing, the plans should show or indicate that more than one footing was considered in designing the seal course and the pay item adjusted accordingly. | |||

Seal Course size shown on plans should not be allowed to be resized as in combining adjacent seal course(s) or lessening thickness without approval from either the Structural Project Manager or Structural Liaison Engineer and an official change order request from district Construction and Materials Division. | |||

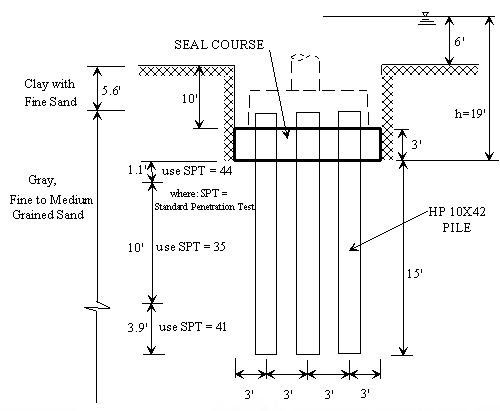

== | ==751.39.3 Example: LRFD Seal Course Design== | ||

Check if Seal Course design is adequate. | Check if Seal Course design is adequate. | ||

| Line 62: | Line 61: | ||

:* 12 - HP 10 x 42 piles | :* 12 - HP 10 x 42 piles | ||

:* Area of an individual HP 10 x 42 Pile = A = 12.4 in<sup>2</sup> | :* Area of an individual HP 10 x 42 Pile = A = 12.4 in<sup>2</sup> | ||

:* Depth of HP shape = 9.7 inch | |||

:* Width of HP shape = 10.1 inch | |||

:* Yield strength of steel F<sub>y</sub> = 36 ksi | :* Yield strength of steel F<sub>y</sub> = 36 ksi | ||

:* Maximum axial load P<sub>y</sub> = F<sub>y</sub> (A) = 36 ksi (12.4 in<sup>2</sup>) = 446.4 kips | :* Maximum axial load P<sub>y</sub> = F<sub>y</sub> (A) = 36 ksi (12.4 in<sup>2</sup>) = 446.4 kips | ||

| Line 70: | Line 71: | ||

[[image:751.39.5.jpg|center|700px|thumb|<center>'''Fig. 751.39.3, Seal Course Elevation'''</center>]] | [[image:751.39.5.jpg|center|700px|thumb|<center>'''Fig. 751.39.3, Seal Course Elevation'''</center>]] | ||

===Solution=== | |||

Factored uplift load per pile: | |||

{| style="margin: 1em auto 1em auto" align=center | |||

{| style="margin: 1em auto 1em auto" align= | |||

|- | |- | ||

|align=left|Uplift force of water = 12'(15')(19')(0.0624 kips/ft<sup>3</sup>) ||= 214 kips | |align=left|Uplift force of water = 12'(15')(19')(0.0624 kips/ft<sup>3</sup>) ||= 214 kips | ||

| Line 89: | Line 85: | ||

|align=left|Net uplift of piles ||= 86 kips | |align=left|Net uplift of piles ||= 86 kips | ||

|- | |- | ||

|colspan="2" align=left| | |colspan="2" align=left|Factored uplift load per pile = 86 kips/12 piles = 7.17 kips/pile | ||

|} | |} | ||

Maximum factored resistance: | |||

Use the minimum of: | |||

(1) Factored resistance for skin friction = Geotechnical resistance factor for skin friction x Nominal skin friction resistance: | |||

:Using "DRIVEN" program, Nominal skin friction resistance of pile is 53.97 kips. | |||

:Geotechnical resistance factor for skin friction = 0.2 for uplift resistance of single pile from LRFD 10.5.5.2.3-1 (Conservatively assumed 0.2), | |||

Factored resistance for skin friction = 0.2 x 53.97 kips = 10.79 kips | |||

(2) Factored resistance for pile tension | |||

:= 0.25 x F<sub>y</sub> x Steel area of pile | |||

:= 0.25 x 36 x 12.4 | |||

:=111.6 kips | |||

(3) Factored resistance for 10 psi adhesion = Structural resistance factor for 10 psi pile adhesion x 10 psi x Pile perimeter x Depth of seal course | |||

Structural resistance for 10 psi pile adhesion, Φ<sub>3</sub> = 1.0 | |||

= 1.0 x 10/1000*2 x (9.7+10.1) x 3 x 12 | |||

= 14.26 kips | |||

Minimum from (1), (2) & (3): | Minimum from (1), (2) & (3): | ||

Maximum factored resistance = 10.79 kips | |||

Factored uplift load per pile = 7.17 kips | |||

7.17 kips ≤ 10.79 kips, O.K. | |||

''' | '''Try seal course depth = 2'-6" ''' | ||

{| style="margin: 1em auto 1em auto" align= | Factored uplift load per pile : | ||

{| style="margin: 1em auto 1em auto" align=center | |||

|- | |- | ||

|align=left|Uplift force of water||= 12'(15')(18.5')(0.0624 kips/ft<sup>3</sup>) = 207.8 kips | |align=left|Uplift force of water||= 12'(15')(18.5')(0.0624 kips/ft<sup>3</sup>) = 207.8 kips | ||

| Line 167: | Line 139: | ||

|Net uplift of piles ||= 101.4 kips | |Net uplift of piles ||= 101.4 kips | ||

|- | |- | ||

| | |Factored uplift load per pile ||= 101.4 kips/12 piles = 8.45 kips/pile | ||

|} | |} | ||

Maximum factored resistance : | |||

Use the minimum of: | |||

(1) Factored resistance for skin friction | |||

:= Geotechnical resistance factor for skin friction x Nominal skin friction resistance | |||

:= 0.2 x 53.97 kips = 10.79 kips | |||

(2) Factored resistance for pile tension = 111.6 kips | |||

(3) Factored resistance for 10 psi pile adhesion = Structural resistance factor for 10 psi pile adhesion x 10 psi x Pile perimeter x Depth of seal course | |||

Structural resistance factor for 10 psi pile adhesion, Φ<sub>3</sub> = 1.0 | |||

= 1.0 x 10/1000*2 x (9.7+10.1) x 2.5 x 12 | |||

= 10.88 kips | |||

Minimum from (1), (2) & (3): | |||

Maximum factored resistance = 10.79 kips | |||

Factored uplift load per pile = 8.45 kips | |||

8.45 kips ≤ 10.79 kips, O.K. | |||

(Using a depth of 2'-6" is an economical design.) | |||

[[Category:751 LRFD Bridge Design Guidelines]] | [[Category:751 LRFD Bridge Design Guidelines]] | ||

Revision as of 14:34, 28 March 2012

1) All pile shall be vertical.

2) For AASHTO Guide Specification for LRFD,

12” for seismic design category A and 18” for seismic design category B, C and D.

751.39.1 General Requirements

Water elevation is to be determined for the site conditions by the preliminary design section; generally, less than the average of high and low water.

Determine the factored uplift load per pile by deducting the weight of the seal course and friction between seal course and sheet piling of cofferdam from the uplift force produced by the hydrostatic head "h".

Use a friction value between the seal course and the sheet piling of 2 lbs./in2 acting on (perimeter x depth) of seal course.

Factored uplift load per pile =

- Load factor for uplift x (Uplift force of water – Weight of seal course – Friction between seal course & sheet piling) / No. of piles

751.39.2 Pile Pull-out Force

Maximum factored resistance per pile shall be determined by the minimum of:

- (1) Factored resistance for skin friction = Geotechnical resistance factor for skin friction x Nominal skin friction resistance

- Use "DRIVEN" program to calculate nominal skin friction resistance of pile (without tip resistance).

- Geotechnical resistance factor for skin friction, φup. from LRFD Table 10.5.5.2.3-1

- Use φup = 0.2 from LRFD table 10.5.5.2.3.-1 for single pile unless higher resistance factor can be justified based on soil type and test method.

- (2) Factored resistance for pile tension = Structural resistance factor for pile tension x Yield strength of steel x Steel area of pile.

- Note: Since CIP pile is not filled at this stage, use steel pipe pile area without concrete to determine the factored resistance for pile tension. ASTM 252 allows “the wall thickness at any point shall not be more than 12.5% under the specified nominal wall thickness. For steel pipe pile area computation consider 87.5% of wall thickness.

- Structural resistance factor for pile tension, φy = 0.25

- (3) Factored resistance for 10 psi adhesion = structural resistance factor for 10 psi adhesion x 10 psi x Pile perimeter x Depth of seal course

- Structural resistance for 10 psi pile adhesion, Φ3 = 1.0

- For HP pile perimeter use 2*(Depth + Width) of HP shape.

Plan Reporting

Seal Course size shall be shown on the plans as designed.

Seal Courses are typically designed for one footing only. They may be designed for uplift loads developed under more than one footing or where there is economy of scale in constructing a larger cofferdam, for example:

- (1) where individual seal courses are proximate and costlier than considering one large seal course under more than one footing, and

- (2) where removal of an existing footing requires a larger cofferdam to be constructed enclosing both existing and new locations of footings with the result that a larger than usual seal course size may be less costlier than individually constructed cofferdams.

Where a seal course is to be designed to resist the uplift loads resulting from the proposed construction of more than one footing, the plans should show or indicate that more than one footing was considered in designing the seal course and the pay item adjusted accordingly.

Seal Course size shown on plans should not be allowed to be resized as in combining adjacent seal course(s) or lessening thickness without approval from either the Structural Project Manager or Structural Liaison Engineer and an official change order request from district Construction and Materials Division.

751.39.3 Example: LRFD Seal Course Design

Check if Seal Course design is adequate.

Given

- Concrete Strength f'c= 3000 psi

- Pile spacing = 3'-0"

- 12 - HP 10 x 42 piles

- Area of an individual HP 10 x 42 Pile = A = 12.4 in2

- Depth of HP shape = 9.7 inch

- Width of HP shape = 10.1 inch

- Yield strength of steel Fy = 36 ksi

- Maximum axial load Py = Fy (A) = 36 ksi (12.4 in2) = 446.4 kips

- Hydrostatic head h = 19'

- Seal Course = 12' x 15' x 3'

- Pile embedment below seal course = 15'

Solution

Factored uplift load per pile:

| Uplift force of water = 12'(15')(19')(0.0624 kips/ft3) | = 214 kips |

| Weight of seal course = 12'(15')(3')(0.15 kips/ft3) | = -81 kips |

| Friction of sheet pile = (15'+12')(2)(3')(144)(0.002kips/in2) | = -47 kips |

| Net uplift of piles | = 86 kips |

| Factored uplift load per pile = 86 kips/12 piles = 7.17 kips/pile | |

Maximum factored resistance:

Use the minimum of:

(1) Factored resistance for skin friction = Geotechnical resistance factor for skin friction x Nominal skin friction resistance:

- Using "DRIVEN" program, Nominal skin friction resistance of pile is 53.97 kips.

- Geotechnical resistance factor for skin friction = 0.2 for uplift resistance of single pile from LRFD 10.5.5.2.3-1 (Conservatively assumed 0.2),

Factored resistance for skin friction = 0.2 x 53.97 kips = 10.79 kips

(2) Factored resistance for pile tension

- = 0.25 x Fy x Steel area of pile

- = 0.25 x 36 x 12.4

- =111.6 kips

(3) Factored resistance for 10 psi adhesion = Structural resistance factor for 10 psi pile adhesion x 10 psi x Pile perimeter x Depth of seal course

Structural resistance for 10 psi pile adhesion, Φ3 = 1.0

= 1.0 x 10/1000*2 x (9.7+10.1) x 3 x 12

= 14.26 kips

Minimum from (1), (2) & (3):

Maximum factored resistance = 10.79 kips

Factored uplift load per pile = 7.17 kips

7.17 kips ≤ 10.79 kips, O.K.

Try seal course depth = 2'-6"

Factored uplift load per pile :

| Uplift force of water | = 12'(15')(18.5')(0.0624 kips/ft3) = 207.8 kips |

| Weight of seal course | = 12'(15')(2.5')(0.15 kips/ft3) = -67.5 kips |

| Friction of sheet pile | = (15'+12')(2)(2.5')(144)(0.002 kips/in2) = -38.9 kips |

| Net uplift of piles | = 101.4 kips |

| Factored uplift load per pile | = 101.4 kips/12 piles = 8.45 kips/pile |

Maximum factored resistance :

Use the minimum of:

(1) Factored resistance for skin friction

- = Geotechnical resistance factor for skin friction x Nominal skin friction resistance

- = 0.2 x 53.97 kips = 10.79 kips

(2) Factored resistance for pile tension = 111.6 kips

(3) Factored resistance for 10 psi pile adhesion = Structural resistance factor for 10 psi pile adhesion x 10 psi x Pile perimeter x Depth of seal course

Structural resistance factor for 10 psi pile adhesion, Φ3 = 1.0

= 1.0 x 10/1000*2 x (9.7+10.1) x 2.5 x 12

= 10.88 kips

Minimum from (1), (2) & (3):

Maximum factored resistance = 10.79 kips

Factored uplift load per pile = 8.45 kips

8.45 kips ≤ 10.79 kips, O.K.

(Using a depth of 2'-6" is an economical design.)