751.32 Concrete Pile Cap Intermediate Bents: Difference between revisions

Jump to navigation

Jump to search

m attached article to new EPG 751 |

m Per Bridge, expanded guidance for encased pile cap bent |

||

| Line 96: | Line 96: | ||

== 751.32.3 Details == | == 751.32.3 Details == | ||

===751.32.3.1 Front Sheet=== | |||

=== 751.32.3. | {|border="0" cellpadding="3" align="center" | ||

|- | |||

|valign="top"|Note:||width="400pt"|The following are details and dimensions for the plan view of a typical pile cap bent on the front sheet of the bridge plans. Details and dimensions for an encased concrete pile cap bent are similar. | |||

|- | |||

| ||width="400pt"|Details for unsymmetrical roadways shall require dimensions tying Centerline Lane to Centerline Structure. | |||

|} | |||

<center>[[Image:751.32 details-front sheet plan of int bent.gif]]</center> | |||

=== 751.32.3.2 Typical Pile Cap Bent === | |||

{|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | {|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | ||

| Line 119: | Line 130: | ||

|- | |- | ||

|valign="top"|[[Image:751.32 circled 4.gif]] | |valign="top"|[[Image:751.32 circled 4.gif]] | ||

|width="500" align="left"|If the depth at the end of the beam, due to the steps, exceeds 4 | |width="500" align="left"|If the depth at the end of the beam, due to the steps, exceeds 4'-6", the beam bottom should be stepped or sloped. | ||

|- | |- | ||

|valign="top"|[[Image:751.32 circled 5.gif]] | |valign="top"|[[Image:751.32 circled 5.gif]] | ||

| Line 128: | Line 139: | ||

|} | |} | ||

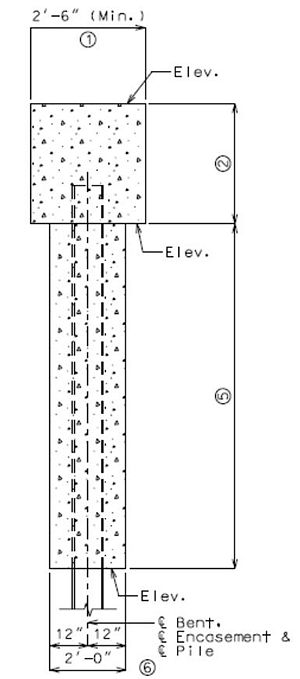

=== 751.32.3. | === 751.32.3.3 Encased Pile Cap Bent=== | ||

{|border="0" cellpadding=" | Consideration shall be given to [http://epg.modot.org/index.php?title=751.1_Preliminary_Design#751.1.2.19_Substructure_Type EPG 751.1.2.19 Substructure Type] before using this type of structure. | ||

{|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | |||

|- | |||

|[[Image:751.32.3.3.1.jpg|center|750px]] | |||

|- | |||

!'''Part Elevation''' | |||

|- | |- | ||

| | |[[Image:751.32.3.3.2.jpg|center|300px]] | ||

|- | |- | ||

| ||width=" | !'''Part Section''' | ||

|} | |||

{|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | |||

|- | |||

|valign="top"|[[Image:751.32 circled 1.gif]] | |||

|width="500" align="left"|Use 2'-6" minimum or as determined by the superstructure requirements or the minimum support length required for earthquake criteria (expansion joint bents only) (3" increments). | |||

|- | |||

|valign="top"|[[Image:751.32 circled 2.gif]] | |||

|width="500" align="left"|= 2'-9" (Min.) for Wide Flange and Double-Tee Girders or,<br/> 3'-0" (Min.) for Prestressed Girders and Plate Girders. | |||

|- | |||

|valign="top"|[[Image:751.32 circled 3.gif]] | |||

|width="500" align="left"|Check the clearance of the anchor bolt well to the top of pile. Increase the beam depth if needed. | |||

|- | |||

|valign="top"|[[Image:751.32 circled 4.gif]] | |||

|width="500" align="left"|If the depth at the end of the beam, due to the steps, exceeds 4'-6", the beam bottom should be stepped or sloped. | |||

|- | |||

|valign="top"|[[Image:751.32 circled 5.gif]] | |||

|width="500" align="left"|Height by design. Embed encasement 2 ft. (min.) below the top of the lowest finished groundline elevation, unless a greater embedment is required for bridge design. | |||

|- | |||

|valign="top"|[[Image:751.32 circled 6.gif]] | |||

|width="500" align="left"|Minimum of 3 piles at 10'-0" cts., maximum spacing (1" increments). | |||

|} | |} | ||

== 751.32.4 Reinforcement == | == 751.32.4 Reinforcement == | ||

=== 751.32.4.1 Typical Pile Cap Bent === | |||

=== 751.32.4.1 | |||

{|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | {|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | ||

| Line 200: | Line 234: | ||

!colspan="2"|Longitudinal Beam Steps | !colspan="2"|Longitudinal Beam Steps | ||

|} | |} | ||

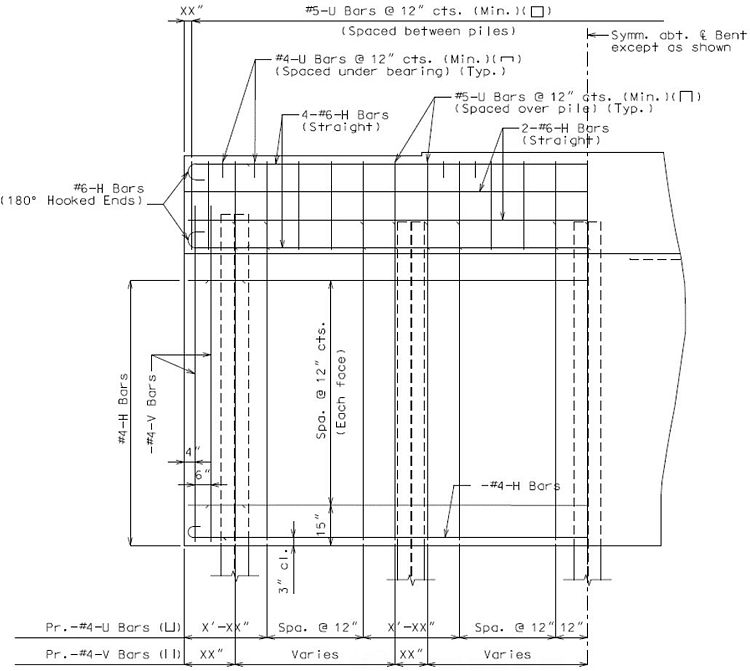

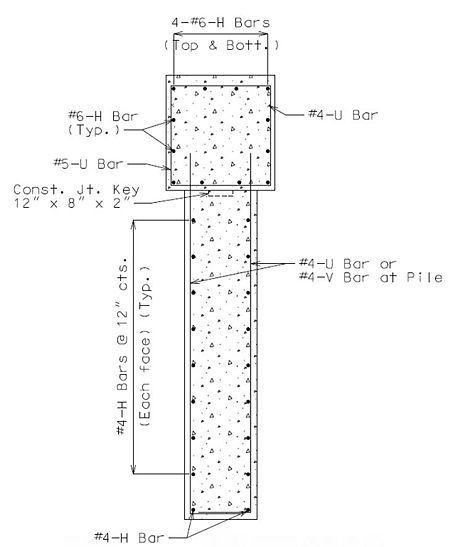

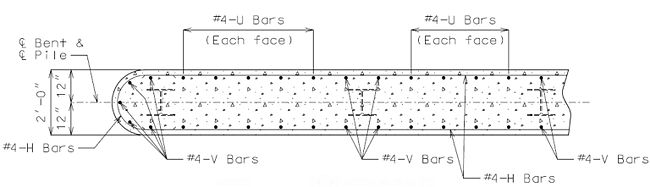

=== 751.32.4.2 Encased Pile Cap Bent=== | |||

Supplemental details for encased pile cap bents are provided. | |||

{|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | |||

|- | |||

|[[image:751.32.4.2 part elev.jpg|center|750px]] | |||

|- | |||

|align="center"|'''Part Elevation''' | |||

|} | |||

{|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | |||

|- | |||

|[[image:751.32.4.2 part section.jpg|center|450px]] | |||

|- | |||

|align="center"|'''Part Section''' | |||

|} | |||

{|border="0" cellpadding="5" align="center" style="text-align:center" cellspacing="0" | |||

|- | |||

|[[image:751.32.4.2 part plan.jpg|center|650px]] | |||

|- | |||

|align="center"|'''Part Plan''' | |||

|} | |||

{|border="0" cellpadding="3" align="center" cellspacing="0" | |||

|- | |||

|valign="top"|Note:||width="500pt" align="left" valign="top"|Locate #4 bars "[[Image:751.32 reinforcement--4 bar under bearing.gif]]" under bearings where required to maintain a 6" maximum spacing of combined stirrups. (#4 bars "[[Image:751.32 reinforcement--4 bar under bearing.gif]]" are not required for Double-Tee Structures.) | |||

|- | |||

| ||width="500pt"|When an expansion device is used at an intermediate bent, all reinforcement located entirely within the beam or extending into the beam shall be epoxy coated. | |||

|} | |||

[[Category:751 LRFD Bridge Design Guidelines]] | [[Category:751 LRFD Bridge Design Guidelines]] | ||

Revision as of 12:29, 26 October 2011

751.32.1 General

751.32.1.1 Material Properties

| Concrete | |||

|---|---|---|---|

| Typically, shall consist of: | |||

| Class B Concrete (Substructure) | = 3.0 ksi | ||

| = 10 | |||

In addition, Class B-1 Concrete (Substructure) may also be used in special cases (See Project Manager). The following equations shall apply to both concrete classes:

Concrete modulus of elasticity:

Where:

| = unit weight of non-reinforced concrete = 0.145 kcf | |

| = correction factor for source of aggregate = 1.0 |

| Modulus of Rupture: | For minimum reinforcement, | |

| For all other calculations, | ||

| is in units of ksi |

Reinforcing Steel

| Minimum yield strength, | = 60.0 ksi | |

| Steel modulus of elasticity, | = 29000 ksi |

751.32.2 Design

751.32.2.1 Limit States and Factors

In general, each component shall satisfy the following equation:

Where:

| = Total factored force effect | |

| = Force effect | |

| = Load modifier | |

| = Load factor | |

| = Resistance factor | |

| = Nominal resistance | |

| = Factored resistance |

Limit States

The following limit states shall be considered for bent design:

- STRENGTH – I

- STRENGTH – III

- STRENGTH – IV

- STRENGTH – V

- SERVICE – I

- FATIGUE

See LRFD Table 3.4.1-1 and LRFD 3.4.2 for Loads and Load Factors applied at each given limit state.

Resistance factors

- STRENGTH limit states, see LRFD 5.5.4.2

- For all other limit states, = 1.00

751.32.3 Details

751.32.3.1 Front Sheet

| Note: | The following are details and dimensions for the plan view of a typical pile cap bent on the front sheet of the bridge plans. Details and dimensions for an encased concrete pile cap bent are similar. |

| Details for unsymmetrical roadways shall require dimensions tying Centerline Lane to Centerline Structure. |

751.32.3.2 Typical Pile Cap Bent

|

|

| (*) 3" (Typ.) | |

| Part Elevation | Part Section |

|---|---|

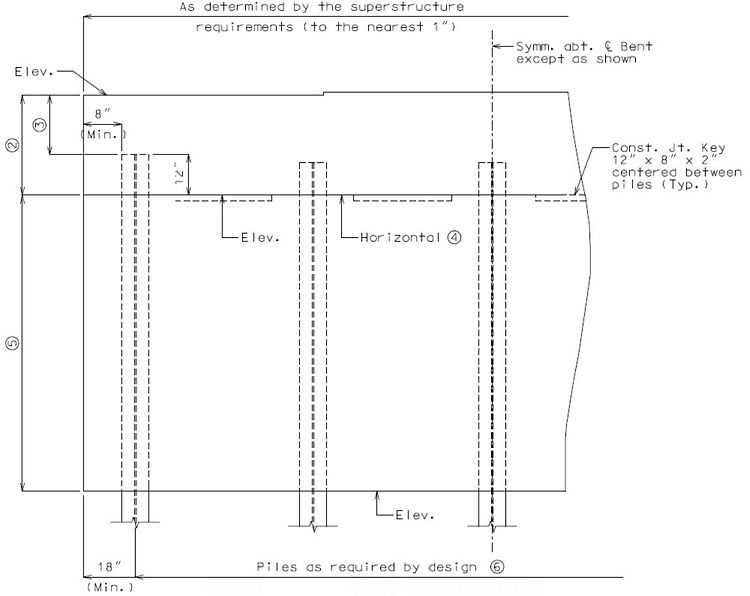

751.32.3.3 Encased Pile Cap Bent

Consideration shall be given to EPG 751.1.2.19 Substructure Type before using this type of structure.

|

| Part Elevation |

|---|

|

| Part Section |

751.32.4 Reinforcement

751.32.4.1 Typical Pile Cap Bent

|

|

| Part Elevation | Section Thru Beam |

|---|---|

|

|

| Part Plan | |

|

|

| * #4 Bars ( | |

| Reinforcement Under Bearings | |

|---|---|

| |

| Transverse Beam Steps - Over 3" or Steps Accumulating Over 3" | |

| |

| Part Plan | |

|---|---|

| |

| Over 3" thru 12" | Over 12" |

| Longitudinal Beam Steps | |

751.32.4.2 Encased Pile Cap Bent

Supplemental details for encased pile cap bents are provided.

|

| Part Elevation |

|

| Part Section |

|

| Part Plan |