Category:601 Field Laboratories: Difference between revisions

m article construction - inclusion of GCM Section 601. |

m Per CM, removed archaic SiteManager info and replaced with AASHTOWARE info |

||

| (12 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[image:601 Field Laboratories.jpg|right|375px|]] | [[image:601 Field Laboratories.jpg|right|375px|]] | ||

Field laboratories are required on jobs as stated in [http://www.modot. | Field laboratories are required on jobs as stated in [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=9 Standard Specification Section 601]. Type 1 (having a minimum 120 ft.<sup>2</sup> floor space) and Type 3 Field Laboratories (having a minimum 200 ft.<sup>2</sup> floor space and a locked storage area for nuclear equipment) are specified at no direct pay. For grading projects requiring a Type 2 Field Laboratory (see Sec 601.4 for a description), the designer is to consult the district construction and materials personnel on the core team to determine whether it is necessary to include a pay item for the laboratory. There may be cases that the project is in close proximity to a Resident Engineer's office so the Type 2 Field Laboratory can be eliminated from the project. Also, a project might be in close proximity to another project in progress where the laboratory can be shared with both projects. | ||

'''Construction Inspection Guidelines''' | ==='''Construction Inspection Guidelines for [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=9 Sec 601]'''=== | ||

====Laboratory Requirements (for Sec 601.2.2)==== | |||

Laboratory approval is accomplished through accreditation by a MoDOT approved program, such as AMRL, or an annual verification of general condition, equipment calibration/verification records and Equipment Verification Samples testing (as needed) by MoDOT. | |||

Condition review is ensuring that the lab adequately meets requirements set forth in the three Field Laboratory Type descriptions. | |||

'''Type 3 Field Laboratory.'' | Equipment record review and physical check will be conducted to ensure equipment records meet the requirements set forth in [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=7 Sec 403.17.3]. This is accomplished by a site visit evaluating condition of equipment inventory and completeness of calibration/verification records. | ||

Calibration/Verification records require: | |||

:1. Detailed results of the work performed (dimensions, mass, force, temperature, etc. | |||

:2. Description of the equipment calibrated including identifying number. | |||

:3. Date the work was performed. | |||

:4. Identification of the individual performing the work. | |||

:5. Identification of the calibration or verification procedure used. | |||

:6. The previous calibration or verification date and next due date. | |||

:7. Identification of any in-house calibration or verification device used (including identification to establish traceability of items such as standard masses, proving rings, standard thermometers, balances, etc.). | |||

Lab Verification/Approval will be recorded in AASHTOWARE Project (AWP) under Qualified Labs. | |||

The Central Lab will assign identification numbers. | |||

The record will include the name of the lab and contact person responsible for the lab oversight. | |||

The company type, facility type, accredation authority and approval date will also be recorded. | |||

====Equipment Verification Samples (Sec 601.2.2.1)==== | |||

Equipment Verification Samples (EVS) are required when QC and QA testing is performed on the same equipment. Samples shall be tested on independent equipment upon startup and at a frequency of once/lab/quarter. The Central Laboratory or district laboratory may be used for this purpose. Sample sizes and specific instructions regarding reporting EVS samples are located in [[:Category:101 Standard Forms# Equipment Verification Samples |QRG – Equipment Verification Samples]]. Equipment requiring a correction factor is exempt, in include Binder Ignition Ovens and Nuclear AC Content Gauges. EVS are not required for small quantities as set forth in [http://www.modot.state.mo.us/business/standards_and_specs/Sec0403.pdf Sec 403.23] or [http://www.modot.state.mo.us/business/standards_and_specs/Sec0502.pdf Sec 502.15.8]. EVS shall not be used in the acceptance decision. Records of EVS should be retained and available for review during lab verification. | |||

Samples shall be submitted as follows for comparison: | |||

<center> | |||

{| border="1" class="wikitable" style="margin: 1em auto 1em auto" style="text-align:left" | |||

|+ | |||

! style="background:#BEBEBE" |Test Method!! style="background:#BEBEBE" |Sample Type | |||

|- | |||

|Gradation – T 27 and T 11 ||Split Sample, Aggregate | |||

|- | |||

|Mat Density (% of Theo. Max) TM 41 or T 166|| Result of core(s) | |||

|- | |||

|FAA – T 304|| Split Sample, Aggregate | |||

|- | |||

|CAA – D 5821|| Split Sample, Aggregate | |||

|- | |||

|Clay Content – T 176|| Split Sample, Aggregate | |||

|- | |||

|Thin & Elongated Particles D 4791|| Split Sample, Aggregate | |||

|- | |||

|Bulk Specific Gravity – T 312 and T 166|| Split Sample, Loose Mix | |||

|- | |||

|Theo. Max. Sp. Gr. – T 209|| Split Sample, Loose Mix | |||

|- | |||

|Pavement Thickness – T 148|| Retest of core(s) | |||

|- | |||

|Concrete Strength – T 22 and T 231|| Cylinder set, Standard Cure 28 day | |||

|} | |||

</center> | |||

Split samples for multiple test may be submitted as a single larger sample from which individual test can be prepared. (Example: A single sample of aggregate may be sent requesting Gradation, Thin and Elongated, FAA, and Clay content as long as the size is adequate to be reduced to the required size for all test requested. Also, a loose mix sample may be submitted for Bulk Specific Gravity and Theoretical Maximum Specific Gravity). | |||

Comparison limits will be as follows: | |||

<center> | |||

{| border="1" class="wikitable" style="margin: 1em auto 1em auto" style="text-align:left" | |||

|+ | |||

|align="center" rowspan="10" width="370"|'''Gradation,<br> Total Percent Passing'''||align="center" width="400"| 100 - ≥ 95 <br>±1.0 | |||

|- | |||

|align="center"|< 95 - ≥ 85 <br>±3.9 | |||

|- | |||

|align="center"|< 85 - ≥ 80 <br>±5.4 | |||

|- | |||

|align="center"|< 80 - ≥ 60 <br>±8.0 | |||

|- | |||

|align="center"|< 60 - ≥ 20 <br>±5.6 | |||

|- | |||

|align="center"|< 20 - ≥ 15 <br>±4.5 | |||

|- | |||

|align="center"|< 15 - ≥ 10 <br>±4.2 | |||

|- | |||

|align="center"|< 10 - ≥ 5 <br>±3.4 | |||

|- | |||

|align="center"|< 5 - ≥ 2 <br>±3.0 | |||

|- | |||

|align="center"|< 2 - ≥ 0 <br>±1.3 | |||

|- | |||

|align="center"|'''Bulk Specific Gravity (applies to both cut cores and compacted specimens)'''||align="center"| Specific gravity ± 0.017 | |||

|- | |||

|align="center"|'''Maximum Specific Gravity'''||align="center"| Maximum specific gravity ± 0.024 for Method A (Mechanical Agitation) or ± 0.029 for Method B (Manual Agitation) | |||

|- | |||

|align="center"|'''Pavement Thickness'''||align="center"| ± 0.2” | |||

|- | |||

|align="center"|'''Compressive Strength'''||align="center"| ± 14% | |||

|} | |||

</center> | |||

If an EVS does not compare favorably, a second sample will be submitted. If tolerances are met, the lab will be deemed satisfactory until the next sample is required. If tolerances are not met, equipment calibration/condition and testing procedures should be checked/reviewed to determine a possible cause for the discrepancy. | |||

EVS samples are associated to the lab in the AWP record. | |||

====Type 1 Field Laboratory (for Sec 601.3)==== | |||

The Type 1 Field Laboratory is mainly required at aggregate producing sources. It is the smallest laboratory and has the fewest requirements. There is no direct payment for the Type 1 Field Laboratory. | |||

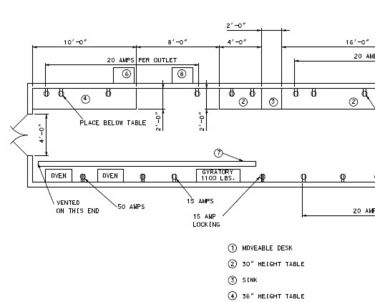

[[image:601.jpg|right|375px]] | |||

====Type 2 Field Laboratory (for Sec 601.4)==== | |||

The Type 2 Field Laboratory is used either as a compaction shack on an active construction project or as the inspector's laboratory at a PCCP concrete plant. When the Type 2 laboratory is used at a PCCP plant it is to be oriented so that the inspector can view plant operations through the window. There is direct payment for this laboratory to offset the contractor's mobilization costs. | |||

====Type 3 Field Laboratory (for Sec 601.5)==== | |||

This laboratory is required at asphalt plants. The contractor must provide equipment required by the specifications governing the type of bituminous mix that is being produced. For example, if the plant is producing Plant Mix Bituminous Pavement, the equipment required by [http://www.modot.mo.gov/business/standards_and_specs/Sec0401.pdf Sec 401] must be provided. If the plant is producing Superpave, the equipment required for [http://www.modot.mo.gov/business/standards_and_specs/Sec0403.pdf Sec 403] must be provided. There is no direct payment for the Type 3 Field Laboratory. | |||

Latest revision as of 09:34, 1 October 2021

Field laboratories are required on jobs as stated in Standard Specification Section 601. Type 1 (having a minimum 120 ft.2 floor space) and Type 3 Field Laboratories (having a minimum 200 ft.2 floor space and a locked storage area for nuclear equipment) are specified at no direct pay. For grading projects requiring a Type 2 Field Laboratory (see Sec 601.4 for a description), the designer is to consult the district construction and materials personnel on the core team to determine whether it is necessary to include a pay item for the laboratory. There may be cases that the project is in close proximity to a Resident Engineer's office so the Type 2 Field Laboratory can be eliminated from the project. Also, a project might be in close proximity to another project in progress where the laboratory can be shared with both projects.

Construction Inspection Guidelines for Sec 601

Laboratory Requirements (for Sec 601.2.2)

Laboratory approval is accomplished through accreditation by a MoDOT approved program, such as AMRL, or an annual verification of general condition, equipment calibration/verification records and Equipment Verification Samples testing (as needed) by MoDOT.

Condition review is ensuring that the lab adequately meets requirements set forth in the three Field Laboratory Type descriptions.

Equipment record review and physical check will be conducted to ensure equipment records meet the requirements set forth in Sec 403.17.3. This is accomplished by a site visit evaluating condition of equipment inventory and completeness of calibration/verification records.

Calibration/Verification records require:

- 1. Detailed results of the work performed (dimensions, mass, force, temperature, etc.

- 2. Description of the equipment calibrated including identifying number.

- 3. Date the work was performed.

- 4. Identification of the individual performing the work.

- 5. Identification of the calibration or verification procedure used.

- 6. The previous calibration or verification date and next due date.

- 7. Identification of any in-house calibration or verification device used (including identification to establish traceability of items such as standard masses, proving rings, standard thermometers, balances, etc.).

Lab Verification/Approval will be recorded in AASHTOWARE Project (AWP) under Qualified Labs.

The Central Lab will assign identification numbers.

The record will include the name of the lab and contact person responsible for the lab oversight.

The company type, facility type, accredation authority and approval date will also be recorded.

Equipment Verification Samples (Sec 601.2.2.1)

Equipment Verification Samples (EVS) are required when QC and QA testing is performed on the same equipment. Samples shall be tested on independent equipment upon startup and at a frequency of once/lab/quarter. The Central Laboratory or district laboratory may be used for this purpose. Sample sizes and specific instructions regarding reporting EVS samples are located in QRG – Equipment Verification Samples. Equipment requiring a correction factor is exempt, in include Binder Ignition Ovens and Nuclear AC Content Gauges. EVS are not required for small quantities as set forth in Sec 403.23 or Sec 502.15.8. EVS shall not be used in the acceptance decision. Records of EVS should be retained and available for review during lab verification.

Samples shall be submitted as follows for comparison:

| Test Method | Sample Type |

|---|---|

| Gradation – T 27 and T 11 | Split Sample, Aggregate |

| Mat Density (% of Theo. Max) TM 41 or T 166 | Result of core(s) |

| FAA – T 304 | Split Sample, Aggregate |

| CAA – D 5821 | Split Sample, Aggregate |

| Clay Content – T 176 | Split Sample, Aggregate |

| Thin & Elongated Particles D 4791 | Split Sample, Aggregate |

| Bulk Specific Gravity – T 312 and T 166 | Split Sample, Loose Mix |

| Theo. Max. Sp. Gr. – T 209 | Split Sample, Loose Mix |

| Pavement Thickness – T 148 | Retest of core(s) |

| Concrete Strength – T 22 and T 231 | Cylinder set, Standard Cure 28 day |

Split samples for multiple test may be submitted as a single larger sample from which individual test can be prepared. (Example: A single sample of aggregate may be sent requesting Gradation, Thin and Elongated, FAA, and Clay content as long as the size is adequate to be reduced to the required size for all test requested. Also, a loose mix sample may be submitted for Bulk Specific Gravity and Theoretical Maximum Specific Gravity).

Comparison limits will be as follows:

| Gradation, Total Percent Passing |

100 - ≥ 95 ±1.0 |

| < 95 - ≥ 85 ±3.9 | |

| < 85 - ≥ 80 ±5.4 | |

| < 80 - ≥ 60 ±8.0 | |

| < 60 - ≥ 20 ±5.6 | |

| < 20 - ≥ 15 ±4.5 | |

| < 15 - ≥ 10 ±4.2 | |

| < 10 - ≥ 5 ±3.4 | |

| < 5 - ≥ 2 ±3.0 | |

| < 2 - ≥ 0 ±1.3 | |

| Bulk Specific Gravity (applies to both cut cores and compacted specimens) | Specific gravity ± 0.017 |

| Maximum Specific Gravity | Maximum specific gravity ± 0.024 for Method A (Mechanical Agitation) or ± 0.029 for Method B (Manual Agitation) |

| Pavement Thickness | ± 0.2” |

| Compressive Strength | ± 14% |

If an EVS does not compare favorably, a second sample will be submitted. If tolerances are met, the lab will be deemed satisfactory until the next sample is required. If tolerances are not met, equipment calibration/condition and testing procedures should be checked/reviewed to determine a possible cause for the discrepancy.

EVS samples are associated to the lab in the AWP record.

Type 1 Field Laboratory (for Sec 601.3)

The Type 1 Field Laboratory is mainly required at aggregate producing sources. It is the smallest laboratory and has the fewest requirements. There is no direct payment for the Type 1 Field Laboratory.

Type 2 Field Laboratory (for Sec 601.4)

The Type 2 Field Laboratory is used either as a compaction shack on an active construction project or as the inspector's laboratory at a PCCP concrete plant. When the Type 2 laboratory is used at a PCCP plant it is to be oriented so that the inspector can view plant operations through the window. There is direct payment for this laboratory to offset the contractor's mobilization costs.

Type 3 Field Laboratory (for Sec 601.5)

This laboratory is required at asphalt plants. The contractor must provide equipment required by the specifications governing the type of bituminous mix that is being produced. For example, if the plant is producing Plant Mix Bituminous Pavement, the equipment required by Sec 401 must be provided. If the plant is producing Superpave, the equipment required for Sec 403 must be provided. There is no direct payment for the Type 3 Field Laboratory.