750.7 Non-Hydraulic Considerations: Difference between revisions

m →750.7.2.2 Roadways with ADT ≤ 3500: corrected PVC diameter limit |

|||

| (4 intermediate revisions by 3 users not shown) | |||

| Line 30: | Line 30: | ||

| Reinforced Concrete || Group A Pipe || Group A Pipe | | Reinforced Concrete || Group A Pipe || Group A Pipe | ||

|- | |- | ||

| Vitrified Clay || ||Group B Pipe | | Vitrified Clay || || Group B Pipe | ||

|- | |- | ||

|Aluminum Coated Steel|| | | Aluminum Coated Steel || Double Wall Polypropylene ≤60 in. || | ||

|- | |- | ||

|Polymer Coated Steel|| | | Polymer Coated Steel || High Density Polyethylene, Corrugated ≤60 in. || Zinc-Coated Steel | ||

|- | |- | ||

|Aluminum Alloy | | Aluminum Alloy || Steel Reinforced Polyethylene ≤60 in. || Bituminous-Coated Steel | ||

|- | |- | ||

|Triple Wall Polypropylene ≤60 in. | | Triple Wall Polypropylene ≤60 in. || rowspan="6" colspan="2" | | ||

|- | |- | ||

|Double Wall Polypropylene ≤30 in | | Double Wall Polypropylene ≤30 in. | ||

|- | |- | ||

|High Density Polyethylene ≤24 in. | | High Density Polyethylene, Corrugated ≤24 in. | ||

|- | |- | ||

|Steel Reinforced Polyethylene ≤24 in. | | Steel Reinforced Polyethylene ≤24 in. | ||

|- | |- | ||

|Polyvinyl chloride ≤36 in. | | Polyvinyl chloride ≤36 in. | ||

|} | |} | ||

| Line 52: | Line 52: | ||

===750.7.2.1 Roadways with ADT > 3500=== | ===750.7.2.1 Roadways with ADT > 3500=== | ||

For roadways with ADT > 3500, | For roadways with ADT > 3500, Group A pipe will be specified for crossroad structures, except for the following conditions: | ||

*Reinforced concrete box culverts are specified when it is more economical to build the reinforced box culvert than it is to provide an equivalent pipe culvert. | *Reinforced concrete box culverts are specified when it is more economical to build the reinforced box culvert than it is to provide an equivalent pipe culvert. | ||

| Line 78: | Line 78: | ||

Pipes of 12 in. and 15 in. are not used for crossroad culverts, except where the use of an 18 in. pipe will create an unsightly or impracticable drainage condition. | Pipes of 12 in. and 15 in. are not used for crossroad culverts, except where the use of an 18 in. pipe will create an unsightly or impracticable drainage condition. | ||

Corrugated polyethylene pipe (Type S) and polyvinyl chloride pipe are double walled, full circular cross section pipes, with an outer corrugated wall and a smooth inner liner. Only 12 to 60 in. diameter sizes of corrugated polyethylene, or 12 to | Corrugated polyethylene pipe (Type S) and polyvinyl chloride pipe are double walled, full circular cross section pipes, with an outer corrugated wall and a smooth inner liner. Only 12 to 60 in. diameter sizes of corrugated polyethylene, or 12 to 36 in. diameter sizes of PVC pipe, are approved for use on highway projects. Corrugations may be either annular or helical. Headwall protection is provided by means of a beveled pipe end treatment, safety slope end section, or metal or concrete flared end sections. [https://www.modot.org/missouri-standard-specifications-highway-construction Section 728] of the Standard Specifications require all PVC pipes to have an end section of one of the other Group B pipe materials to protect from ultraviolet degradation where the end of the pipe is exposed. | ||

===750.7.2.3 Roadways and Roadside Applications with ADT < 1700=== | ===750.7.2.3 Roadways and Roadside Applications with ADT < 1700=== | ||

For roadways, side roads, and entrances with ADT < 1700 Group C pipe should be specified using the same method for corrugated and smooth wall Group B pipe as explained in [[#750.7.2.2 Roadways with ADT ≤ 3500|Roadways with ADT ≤ 3500]]. For information regarding replacement of failed driveway drainage pipes see [[:Category:941 Permits and Access Requests#941.9.8.4 Drainage Structures|EPG 941.9.8.4 Drainage Structures]]. | For roadways, side roads, and entrances with ADT < 1700 Group C pipe should be specified using the same method for corrugated and smooth wall Group B pipe as explained in [[#750.7.2.2 Roadways with ADT ≤ 3500|Roadways with ADT ≤ 3500]]. For information regarding replacement of failed driveway drainage pipes see [[:Category:941 Permits and Access Requests#941.9.8.4 Drainage Structures|EPG 941.9.8.4 Drainage Structures]]. | ||

===750.7.2.4 | ===750.7.2.4 Outer Roadway Drainage Structures=== | ||

Outer roadway drainage structures shall be selected by ADT as described above. Continuous drainage structures extending under outer roadways are designed to the same standard as required for the portion of the structure under the main roadway. Since a continuous drainage structure usually increases the standard for the portion under the outer roadway, it is usually more economical to use independent structures. Where continuous structures are used, the runoff between the outer roadway and the main roadway is usually carried into the crossroad structure by drop inlets and pipe. Where the crossroad structure is a relatively small pipe, the drop inlet is constructed in the crossroad structure. | Outer roadway drainage structures shall be selected by ADT as described above. Continuous drainage structures extending under outer roadways are designed to the same standard as required for the portion of the structure under the main roadway. Since a continuous drainage structure usually increases the standard for the portion under the outer roadway, it is usually more economical to use independent structures. Where continuous structures are used, the runoff between the outer roadway and the main roadway is usually carried into the crossroad structure by drop inlets and pipe. Where the crossroad structure is a relatively small pipe, the drop inlet is constructed in the crossroad structure. | ||

For drainage applications other than crossroad pipes, such as entrances, side roads and median drainage, Group C pipe may be specified | For drainage applications other than crossroad pipes, such as entrances, side roads and median drainage, Group C pipe may be specified. In special cases where low clearance exists and the structure is essentially at right angles on roads with less than 400 ADT, pipe arches with flared end sections may be specified. | ||

===750.7.2.5 Installations for Special Situations=== | ===750.7.2.5 Installations for Special Situations=== | ||

| Line 321: | Line 319: | ||

:1) No guardrail required if [[231.2 Clear Zones|clear zones]] are provided. | :1) No guardrail required if [[231.2 Clear Zones|clear zones]] are provided. | ||

:2) For smaller box culverts a long span guardrail system as shown in [ | :2) For smaller box culverts a long span guardrail system as shown in [https://www.modot.org/media/16856 Standard Plan 606.00] may be used to eliminate posts over the culvert. | ||

Guardrail posts attached to the top slab of the culvert shall have at least a 10” distance between the face of the headwall and the center of the guardrail post. | Guardrail posts attached to the top slab of the culvert shall have at least a 10” distance between the face of the headwall and the center of the guardrail post. | ||

| Line 330: | Line 328: | ||

==750.7.5 Pipe Headwalls== | ==750.7.5 Pipe Headwalls== | ||

Type S pipe headwalls may be used in lieu of drop inlets for median pipes for medians 60 ft. wide or wider. Details for Type S pipe headwalls are shown on [ | Type S pipe headwalls may be used in lieu of drop inlets for median pipes for medians 60 ft. wide or wider. Details for Type S pipe headwalls are shown on [https://www.modot.org/media/16844 Standard Plan 604.05]. | ||

==750.7.6 End Treatment== | ==750.7.6 End Treatment== | ||

| Line 343: | Line 341: | ||

| colspan="2" | <center>Crossroad Culverts</center>|| colspan="2" | <center>Parallel Culverts</center>|| rowspan="4" | <center>Permissible to have no end treatment; consider FES or BET especially for ADT ≥ 400</center> | | colspan="2" | <center>Crossroad Culverts</center>|| colspan="2" | <center>Parallel Culverts</center>|| rowspan="4" | <center>Permissible to have no end treatment; consider FES or BET especially for ADT ≥ 400</center> | ||

|- | |- | ||

| <center>Single Pipes</center> || <center>Multiple Pipes</center> || <center>Single Pipes</center> || <center>Multiple Pipes</center> | | <center>Single Pipes</center> || <center>Multiple Pipes</center> || <center>Single Pipes</center> || <center>Multiple Pipes</center> | ||

|- | |- | ||

| <center>≤ 36 in. diameter use BET or FES</center>|| <center>≤ 30 in. diameter use BET or FES</center>|| <center>≤ 24 in. diameter BET or FES</center>|| rowspan="2" | <center>Consider SSES for ≤ 24 in. diameter</center> | | <center>≤ 36 in. diameter use BET or FES</center>|| <center>≤ 30 in. diameter use BET or FES</center>|| <center>≤ 24 in. diameter BET or FES</center>|| rowspan="2" | <center>Consider SSES for ≤ 24 in. diameter</center> | ||

|- | |- | ||

| <center>> 36 in. diameter use SSES</center> || <center>> 30 in. diameter use SSES</center> || <center>> 24 in. diameter use SSES</center> | | <center>> 36 in. diameter use SSES</center> || <center>> 30 in. diameter use SSES</center> || <center>> 24 in. diameter use SSES</center> | ||

|- | |- | ||

| colspan="5" | FES = Flared End Section<br/>BET = Beveled Pipe End Treatment<br/>SSES = Safety Slope End Section | | colspan="5" | FES = Flared End Section<br/>BET = Beveled Pipe End Treatment<br/>SSES = Safety Slope End Section | ||

| Line 353: | Line 351: | ||

===750.7.6.1 Flared End Sections=== | ===750.7.6.1 Flared End Sections=== | ||

Flared end sections may be used on concrete, metal, or plastic pipes as shown on [ | Flared end sections may be used on concrete, metal, or plastic pipes as shown on [https://www.modot.org/media/16975 Standard Plan 732.00]. Where flared end sections are used on skewed pipe, the section is placed on the same line as the pipe and the fill slope is warped to fit. | ||

===750.7.6.2 Beveled Pipe End Treatment=== | ===750.7.6.2 Beveled Pipe End Treatment=== | ||

Beveled pipe end treatment may be used on either corrugated metal or plastic pipes as shown on [ | Beveled pipe end treatment may be used on either corrugated metal or plastic pipes as shown on [https://www.modot.org/media/16976 Standard Plan 732.05]. All beveled pipes use encasement. Corrugated steel pipe-arches are not beveled. In general, the bevel should not be flatter than 1V:6H nor should the skew exceed 15 degrees. If these controls are exceeded, special consideration is given to the use of headwalls, riprap, or slope pavement to stiffen the structure against uneven loading from the embankment and the dynamic forces of the water. Proposed designs for these conditions are submitted to the Support Center for approval. | ||

===750.7.6.3 Safety Slope End Sections=== | ===750.7.6.3 Safety Slope End Sections=== | ||

Safety slope end sections are used to reduce the potential for vehicle snagging. End sections with two types of safety treatment for 1V:4H, 1V:6H and 1V:10H slopes are shown in [ | Safety slope end sections are used to reduce the potential for vehicle snagging. End sections with two types of safety treatment for 1V:4H, 1V:6H and 1V:10H slopes are shown in [https://www.modot.org/media/16977 Standard Plan 732.10]. The 2B (Summary of Quantities) sheet should indicate the slope of the end section and whether the end section is for a crossroad or parallel drainage structure. | ||

===750.7.6.4 Floodgates=== | ===750.7.6.4 Floodgates=== | ||

| Line 462: | Line 460: | ||

==750.7.17 Slotted Drains== | ==750.7.17 Slotted Drains== | ||

Slotted drains may be used to assist in drainage across entrances or very short sections of the roadway edge. Consistent hydraulic characteristics are not available, so slotted drains should not be expected to completely drain a pavement area. Chapter 4 of the FHWA Hydraulic Engineering Circular 22, "HEC-22 Urban Drainage Design" provides guidance for the design of slotted drains. The plans provide for the contractor to select among different styles of slotted drains (See [ | Slotted drains may be used to assist in drainage across entrances or very short sections of the roadway edge. Consistent hydraulic characteristics are not available, so slotted drains should not be expected to completely drain a pavement area. Chapter 4 of the FHWA Hydraulic Engineering Circular 22, "HEC-22 Urban Drainage Design" provides guidance for the design of slotted drains. The plans provide for the contractor to select among different styles of slotted drains (See [https://www.modot.org/media/16854 Standard Plan 604.70]). The diameter of pipe and length of slotted drain are specified in the plans. | ||

[[Category:750 Hydraulic Analysis]] | [[Category:750 Hydraulic Analysis]] | ||

Latest revision as of 12:55, 20 May 2024

| Metal and Concrete Pipe |

| Report 2008 |

| High Density Polyethylene (HDPE) Pipe Culverts |

| Summary 2002 |

| Report 2002 |

| Summary 2002 |

| Report 2002 |

| See also: Research Publications |

750.7.1 General

Drainage structures are located and designed to adequately handle runoff across improvements and to handle runoff from the improvement. Non-Hydraulic Considerations presents criteria pertaining to the selection of culvert and storm sewer material and appurtenances. The hydraulic design of culverts and other drainage facilities is discussed in other articles under Hydraulic Analysis.

750.7.2 Types

Permissible culvert pipe types are separated into the following groups.

| Group A (ADT>3500) | Group B (ADT≤3500) | Group C (Other Applications) |

|---|---|---|

| Reinforced Concrete | Group A Pipe | Group A Pipe |

| Vitrified Clay | Group B Pipe | |

| Aluminum Coated Steel | Double Wall Polypropylene ≤60 in. | |

| Polymer Coated Steel | High Density Polyethylene, Corrugated ≤60 in. | Zinc-Coated Steel |

| Aluminum Alloy | Steel Reinforced Polyethylene ≤60 in. | Bituminous-Coated Steel |

| Triple Wall Polypropylene ≤60 in. | ||

| Double Wall Polypropylene ≤30 in. | ||

| High Density Polyethylene, Corrugated ≤24 in. | ||

| Steel Reinforced Polyethylene ≤24 in. | ||

| Polyvinyl chloride ≤36 in. | ||

In general, there are two methods of specifying the permissible culvert types dependent upon the design ADT. For most applications, a group of culvert types is specified as described in succeeding sections. For special situations, a qualified pipe group may be specified, as described in Installations for Special Situations. The final selection of the structure type is based on requirements in the standard specifications, on good engineering judgment, and economy with consideration of service and maintenance costs.

750.7.2.1 Roadways with ADT > 3500

For roadways with ADT > 3500, Group A pipe will be specified for crossroad structures, except for the following conditions:

- Reinforced concrete box culverts are specified when it is more economical to build the reinforced box culvert than it is to provide an equivalent pipe culvert.

- Vitrified clay pipe (extra strength) is specified when the purpose of the culvert is a sanitary sewer.

- Group B pipe should be specified for the portion of median outlet pipes outside the edge of pavement where such pipes are located on high fills requiring a break in flowline grade. Details for such installations are illustrated in Pipe Grades For Median Drop Inlets.

- Group B pipe is specified to drain drop inlets into crossroad drainage structures when such installation necessitates a steep flowline grade and when the pipe will not extend under the pavement or in other non-traffic areas, such as behind guardrail at median piers.

Pipes of 12 in. and 15 in. are not used except as outlets from drop inlets and in storm sewer systems.

The requirements for using reinforced concrete pipe or vitrified clay pipe for structures may be waived if conditions warrant, such as poor structure foundation conditions, high fills, simplification of handling traffic, etc.

750.7.2.2 Roadways with ADT ≤ 3500

For roadways with ADT ≤ 3500, Group B pipe should be specified for crossroad structures. The hydraulic design computations for Group B pipe should be performed for both corrugated and smooth wall pipe. The pay item for the corrugated pipe size should be used. At each pipe location on the plans, both the corrugated and equivalent smooth wall diameters should be shown as in the following examples:

- 36" Group B Pipe (30")

- 36" Group B Pipe (36")

The equivalent smooth wall diameter must be shown whether the size is equal to or less than the corrugated size. The standard specifications for pipe and end sections describe the nomenclature for this procedure. Some exceptions to specifying Group B on the plans are the following:

- Reinforced concrete box culverts should be considered for pipes larger than 60 in. diameter.

- Reinforced concrete pipe, corrugated polyethylene pipe or polyvinyl chloride pipe should be specified for locations where high acidity or alkalinity of soils or waters or other abrasive or corrosive elements are present.

- Corrugated metallic-coated steel pipe-arch structures in sizes B-5 and larger may be specified where necessary because of limited allowable structure height. A battery of round pipes or a single elliptical reinforced concrete pipe may be considered in lieu of B-1 through B-4 corrugated metallic-coated steel pipe-arch structures.

- Elliptical reinforced concrete pipe may be specified in special cases, usually for storm sewers, where necessary because of limited allowable structure height.

Pipes of 12 in. and 15 in. are not used for crossroad culverts, except where the use of an 18 in. pipe will create an unsightly or impracticable drainage condition.

Corrugated polyethylene pipe (Type S) and polyvinyl chloride pipe are double walled, full circular cross section pipes, with an outer corrugated wall and a smooth inner liner. Only 12 to 60 in. diameter sizes of corrugated polyethylene, or 12 to 36 in. diameter sizes of PVC pipe, are approved for use on highway projects. Corrugations may be either annular or helical. Headwall protection is provided by means of a beveled pipe end treatment, safety slope end section, or metal or concrete flared end sections. Section 728 of the Standard Specifications require all PVC pipes to have an end section of one of the other Group B pipe materials to protect from ultraviolet degradation where the end of the pipe is exposed.

750.7.2.3 Roadways and Roadside Applications with ADT < 1700

For roadways, side roads, and entrances with ADT < 1700 Group C pipe should be specified using the same method for corrugated and smooth wall Group B pipe as explained in Roadways with ADT ≤ 3500. For information regarding replacement of failed driveway drainage pipes see EPG 941.9.8.4 Drainage Structures.

750.7.2.4 Outer Roadway Drainage Structures

Outer roadway drainage structures shall be selected by ADT as described above. Continuous drainage structures extending under outer roadways are designed to the same standard as required for the portion of the structure under the main roadway. Since a continuous drainage structure usually increases the standard for the portion under the outer roadway, it is usually more economical to use independent structures. Where continuous structures are used, the runoff between the outer roadway and the main roadway is usually carried into the crossroad structure by drop inlets and pipe. Where the crossroad structure is a relatively small pipe, the drop inlet is constructed in the crossroad structure.

For drainage applications other than crossroad pipes, such as entrances, side roads and median drainage, Group C pipe may be specified. In special cases where low clearance exists and the structure is essentially at right angles on roads with less than 400 ADT, pipe arches with flared end sections may be specified.

750.7.2.5 Installations for Special Situations

For installations on a project which normally would require a pipe group option, special conditions may exist which would justify the specifying of a qualified pipe group type. Justification for the selection of a qualified group pipe type include, but are not limited to, unstable foundation, high embankments, high erosive forces, highly abrasive or corrosive conditions, high fire hazard or other pertinent reasons. When any one or a combination of these factors exist, the culvert pipe type(s) best suited to resist such destructive forces is selected and specified by excluding pipe types from a specified group with a note on the plans or Job Special Provision. When a qualified pipe group is specified, the reasons for such selection are included in the letter of transmittal of the plans.

750.7.2.6 Storm Sewers

The permissible storm sewer type under the paved portion and any planned widening of roadways with ADT greater than 3500 is Group A pipe. All other applications of storm sewer are Group B pipe. The standard specifications require that corrugated metal culvert pipes used for storm sewer be smooth interior pipe types, so that consistent hydraulic characteristics may be assumed during design of the entire interconnected system.

750.7.2.7 Multiple Opening Installations

Multiple opening structures, either boxes or pipes, are used only as required where the allowable structure height is restricted. Where multiple pipes are constructed, the pipes are separated by a distance of 1/2 their outside diameter, or a minimum of 1 ft., whichever is greater.

750.7.2.8 Temporary Installations

For bypasses, crossovers or other temporary installations, regardless of design ADT, Group C pipe should be specified using the same method as for corrugated and smooth wall Group B pipe as explained in Roadways with ADT ≤ 3500.

750.7.3 Environmental Requirements

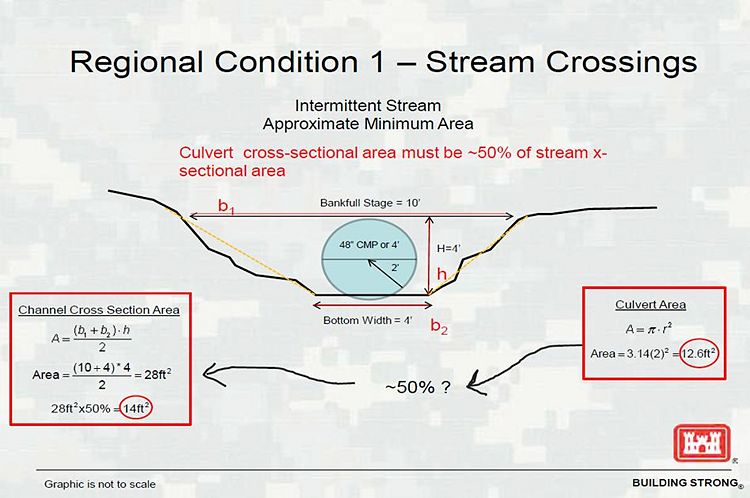

Waters of the United States are under the jurisdiction of the U.S. Army Corps of Engineers (COE) which has implemented a Regional Condition, affecting new and replacement culverts, to Section 404 Nationwide Permits (all Nationwide Permits including NWP 14, Linear Transportation Projects and NWP 3, Maintenance Activities) for Missouri.

If meeting the requirements of the Regional Condition is not feasible, or requires unreasonable measures or expense, a waiver can be requested from the COE. For more information, or to request a waiver, contact a Wetlands Specialist in the Environmental Section of the Design Division.

| Summary of COE Regional Condition Requirements for New and Replacement Culverts | |||||||

|---|---|---|---|---|---|---|---|

| Culvert Opening Width (Total Width of All Culverts Within the Stream)1 |

≤ 4 ft. | > 4 ft. | |||||

| Invert Embedment | Flush or Below Natural Stream Bottom | Stream Type | Perennial Intermittent |

1 ft. (min.) below natural stream bottom2 | |||

| Ephemeral | Flush or Below Natural Stream Bottom | ||||||

| Hydraulics | Stream Type | Perennial | Flow Area | No requirement | Minimum of 85% of Bankfull Flow Area (Includes culvert(s) and roadway overtopping flow below bankfull stage.) | ||

| Intermittent | Minimum of 50% of Bankfull Flow Area (Includes culvert(s) and roadway overtopping flow below bankfull stage.) | ||||||

| Ephemeral | No Requirement | ||||||

| 1 Diameter for circular culverts; multiple culverts or barrels are considered to be one culvert | |||||||

| 2 Flush with natural stream bottom for streams with non-erodible beds. | |||||||

750.7.3.1 Stream Classifications

A list, of perennial and intermittent streams, is available in EPG 127.4.1.1 Overview. This list does not include all perennial and intermittent streams in the state. Streams not listed in this list or thought to be a different class than what is represented, should be further evaluated to determine their classification. The Wetlands Specialist in the Environmental Section of the Design Division will likely have visited the site and have, photos and/or, notes on the stream classification. The following sources are examples of information that may be used to aid in determination of the stream classification:

- Survey Field Notes from Wetland Specialist and/or Survey Crew

- Bridge Survey Report

- USGS Topographical Maps

- Photos

- Aerial or Satellite Imagery

750.7.3.2 Embedment Requirements

The regional condition encourages the use of single culverts. If multiple culverts are used, all must be embedded to the same invert elevation.

- Perennial and Intermittent Streams

- Total width of all culverts within the stream channel > 4’ (diameter for circular culverts):

- Culvert Extensions and Repairs – No Embedment Required

- New and Replacement Culverts

- 1’ minimum embedment of culvert invert below natural stream bottom, except that:

- Invert may be placed flush with stream bottom in non-erodible channels.

- Invert should be embedded deeper in streams with highly erodible beds.

- Total width of all culverts within the stream channel < 4’ (diameter for circular culverts):

- Invert placed flush with stream bottom, except that:

- Invert should be embedded in streams with highly erodible beds.

- Total width of all culverts within the stream channel > 4’ (diameter for circular culverts):

- Ephemeral Streams

- Culvert Extensions and Repairs – No Embedment Required

- New and Replacement Culverts

- Invert placed flush with stream bottom, except that:

- Invert should be embedded in streams with highly erodible beds.

The embedded area shall be allowed to naturally backfill and shall not be included as part of the flow area for hydraulic design calculations.

On streams with highly erodible beds, grade control measures may be applied as necessary to prevent erosion and maintain aquatic life movement.

750.7.3.3 Hydraulic Requirements

In addition to the embedment requirements, new and replacement culverts with a width (diameter for circular culverts) greater than 4 ft. (total width of all culverts within the stream channel), on perennial and intermittent streams are required to convey a portion of the bankfull flow area.

Bankfull flow area is the area within the stream channel between the bankfull stage and the bottom of the channel. Bankfull stage is defined as the lowest bank elevation where water begins to overflow on the floodplain. On highly incised streams, where the bankfull stage is higher than a 100-yr. flood event, contact a Wetlands Specialist in the Environmental section for consultation with the Corps to determine the appropriate bankfull stage.

Once the bankfull stage and associated area have been determined the minimum area of the culvert can be determined. The Regional Condition provides guidance for the following regulated stream types:

- 1) Perennial streams: 85% of the bankfull area shall remain open. This may be a combination of the culvert opening(s) and roadway overtopping flow below the bankfull stage.

- 2) Intermittent streams: 50% of the bankfull area shall remain open. This may be a combination of the culvert opening(s) and roadway overtopping flow below the bankfull stage.

750.7.4 Box Culverts

| Additional Info for the Districts |

| The Bridge Division has prepared the Reference Guide SBC for laying out and plan reporting details of concrete single box culverts (SBC) using the standard plans. |

750.7.4.1 Standard Plans

The standard plans were designed for the HL-93 design loading. The standard plans may be used for all culverts on the state system with design fill heights of one foot thru 50 feet.

| General Details | |

|---|---|

| Wing J-bars & Wing Backfill Slopes | 703.37 |

| Cutting Details for Partial Removal | 703.38 |

| Pipe Inlets | 703.60 |

| Bar Supports for Concrete | 706.35 |

| Culvert Details | Single Box | Double Box | Triple Box |

|---|---|---|---|

| Square - Straight Wings | 703.10 | 703.40 | 703.80 |

| Square - Flared Wings | 703.11 | 703.41 | 703.81 |

| Left Ahead - Straight Wings | 703.12 | 703.42 | 703.82 |

| Left Ahead - Flared Wings | 703.13 | 703.43 | 703.83 |

| Right Ahead - Straight Wings | 703.14 | 703.44 | 703.84 |

| Right Ahead - Flared Wings | 703.15 | 703.45 | 703.85 |

| Cut Sections | 703.16 | 703.46 | 703.86 |

| Member Size & Reinforcement Tables | 703.17 | 703.47 | 703.87 |

| Span (ft.) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |||

| Height (ft.) |

2 | X | X | 2 | ||||||||||||

| 3 | X | X | X | X | 3 | |||||||||||

| 4 | X | X | X | X | X | X | 4 | |||||||||

| 5 | X | X | X | X | X | X | X | X | 5 | |||||||

| 6 | A | X | X | X | X | X | X | X | X | X | 6 | |||||

| 7 | X | X | X | X | X | X | X | X | X | X | X | 7 | ||||

| 8 | X | X | X | X | X | X | X | X | X | X | X | X | 8 | |||

| 9 | X | X | X | X | X | X | X | X | X | X | X | 9 | ||||

| 10 | X | X | X | X | X | X | X | X | X | X | 10 | |||||

| 11 | X | X | X | X | X | X | X | X | X | 11 | ||||||

| 12 | X | X | X | X | X | X | X | X | 12 | |||||||

| 13 | X | X | X | X | X | X | X | 13 | ||||||||

| 14 | X | X | X | X | X | X | 14 | |||||||||

| 15 | X | X | X | X | X | 15 | ||||||||||

| 16 | X | X | X | X | 16 | |||||||||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |||

| X = single, double and triple box | ||||||||||||||||

| A = double and triple box only | ||||||||||||||||

750.7.4.2 Abrasion of Interior Surfaces

The Core Team shall determine whether abrasion of the interior surfaces of the box culvert from large rocks or boulders is likely. If abrasion is to be considered, a structural design performed by the Bridge Division will be required. For guidance in determining when abrasion should be considered in culvert design, refer to the following documents:

- • Schall, J.T., etal., 2012 Hydraulic Design of Highway Culverts – Hydraulic Design Series No. 5 (HDS-5), Federal Highway Administration, Publication No. FHWA-HIF-0112-026

- • NRC. 1978. “Durability of Drainage Pipe.” NCHRP Synthesis of Highway Practice No. 50. Transportation Research Board, National Research Council, Washington, DC, p. 37.

750.7.4.3 Summary of Responsibilities

| Drainage Area (Acres) | Number of Cells | Design Fill in Standard Plans | Responsible Entity | Bridge Number | Pay Items, Job Specials, Estimate | |

|---|---|---|---|---|---|---|

| Hydraulics | Final Plans | |||||

| <1000 | 1 | Yes | District | District* | No | Roadway |

| <1000 | 1 | No | District | Bridge Division** | No | Roadway |

| <1000 | 2 or 3 | N/A | District | Bridge Division | Yes | Bridge |

| >1000 | 1, 2 or 3 | N/A | Bridge Division | Bridge Division | Yes | Bridge |

| * Bridge Division will produce a typical section for the district to use in roadway plans (including quantities per foot) when abrasion design is required | ||||||

| ** Bridge Division will produce a typical section for the district to use in roadway plans (including quantities per foot) | ||||||

For drainage areas of 1000 acres and less which require a structure designed by Bridge Division (multiple cell box, etc.), the district shall make the necessary hydraulic analysis and provide the following information to Bridge Division for each structure for placement on the plans:

- Box Culvert Size

- Drainage Area

- Base Flood Elevation, discharge, backwater and culvert outlet velocity.

- Design Flood Elevation, Design Frequency and discharge.

- Overtopping Flood discharge and frequency.

Multiple cell box structures for drainage areas of 1000 acres and under require that the final plans be done by Bridge Division. Where such plans are required, Bridge Division shall be furnished with the grade across the structure, typical section, and any other necessary information.

750.7.4.4 Size

Hydraulic and environmental factors will control the required size of the box culvert. The size of the box culvert will affect the fill slopes and the culvert length. In special cases, a more economical box culvert may be attained by increasing the height of the culvert opening. Box culvert sizes are indicated on the plans as "(span) x (height)".

750.7.4.5 Guardrail Attachment

When guardrail is provided over a box culvert and the fill over the culvert provides less than 3’ 8” embedment of guardrail posts, guardrail attachments to the culvert shall be provided unless one of the following applies:

- 1) No guardrail required if clear zones are provided.

- 2) For smaller box culverts a long span guardrail system as shown in Standard Plan 606.00 may be used to eliminate posts over the culvert.

Guardrail posts attached to the top slab of the culvert shall have at least a 10” distance between the face of the headwall and the center of the guardrail post.

750.7.4.6 Concrete Type

All district designed concrete culvert designs should use Class B-1 Concrete, as reflected in the general notes of the culvert design standard plans. For these items, unit bid item 7034041 CLASS B1 CONCRETE (CULVERTS) should be used.

750.7.5 Pipe Headwalls

Type S pipe headwalls may be used in lieu of drop inlets for median pipes for medians 60 ft. wide or wider. Details for Type S pipe headwalls are shown on Standard Plan 604.05.

750.7.6 End Treatment

End treatments on culverts provide safety benefits for errant vehicles, improved structural support for pipe ends, and improved hydraulic flow for pipe entrances. All pipe ends in the clear zone require some type of end treatment. Outside of the clear zone, considerations of hydraulics, aesthetics or soil erosion may warrant the use of an end section.

The following table contains minimum usage of end treatments as discussed in the Roadside Design Guide. This table and the following discussion should be used with site specific factors, including maintenance concerns, to determine the safe and cost-effective end treatment for each culvert. The Roadside Design Guide (Chapter 3) has additional discussion of cross-drainage and parallel drainage structures.

| Within Clear Zone | Outside Clear Zone | |||

|---|---|---|---|---|

| FES = Flared End Section BET = Beveled Pipe End Treatment SSES = Safety Slope End Section | ||||

750.7.6.1 Flared End Sections

Flared end sections may be used on concrete, metal, or plastic pipes as shown on Standard Plan 732.00. Where flared end sections are used on skewed pipe, the section is placed on the same line as the pipe and the fill slope is warped to fit.

750.7.6.2 Beveled Pipe End Treatment

Beveled pipe end treatment may be used on either corrugated metal or plastic pipes as shown on Standard Plan 732.05. All beveled pipes use encasement. Corrugated steel pipe-arches are not beveled. In general, the bevel should not be flatter than 1V:6H nor should the skew exceed 15 degrees. If these controls are exceeded, special consideration is given to the use of headwalls, riprap, or slope pavement to stiffen the structure against uneven loading from the embankment and the dynamic forces of the water. Proposed designs for these conditions are submitted to the Support Center for approval.

750.7.6.3 Safety Slope End Sections

Safety slope end sections are used to reduce the potential for vehicle snagging. End sections with two types of safety treatment for 1V:4H, 1V:6H and 1V:10H slopes are shown in Standard Plan 732.10. The 2B (Summary of Quantities) sheet should indicate the slope of the end section and whether the end section is for a crossroad or parallel drainage structure.

750.7.6.4 Floodgates

Floodgates are specified for the outlet ends of pipes where required to prevent floodwater from backing through the pipe. Type 1 floodgates are specified for concrete pipes. Floodgates for concrete box structures will require a special item number and special provision. Type 2 floodgates are specified on corrugated metal pipes. The hydraulic head should be specified on the plans. If the hydraulic head is not specified on the plans, the height of fill above the pipe will be considered the hydraulic head. The number of floodgates is listed on the plans in accordance with pipe sizes.

For information maintenance of floodgates, see EPG 614.5 Maintenance of Floodgates.

750.7.7 Circular Reinforced Concrete Pipes

750.7.7.1 Classes of Strength

Reinforced concrete pipe is available as any one of five classes designated as Class I, II, III, IV or V. Class V pipe is the strongest design.

750.7.7.2 Use of Various Classes

Class I and II pipes are used only for sewers in trenches outside roadbed and street limits. Class I pipe is provided in 60 to 108 in. diameters, inclusive, and is used with fill 12 ft. or less in depth. Class II and III pipes are provided in sizes from 12 in. to 108 in. diameters, inclusive. Class II pipe is used with fill 15 ft. or less in depth and Class III pipe is used with fill 21 ft. or less in depth. Class IV pipe is provided in 12 in. to 84 in. Diameters, inclusive, and is used with fill 33 ft. or less in depth. Class V pipe is provided in sizes from 12 in. to 72 in. diameters, inclusive, and is used with fill 51 ft. or less in depth.

750.7.7.3 Selection of Pipe Class and Installation Type

In order for the contractor to select the most economical class of reinforced concrete pipe, the fill height must be shown on the culvert sheets. As shown on Standard Plan 726.30, a range of installation types can be used for each soil category; however, the proper installation type will correspond to the most economical, lowest class of pipe for a given fill height.

750.7.7.4 Special Design Reinforced Concrete Pipe

Since pipes are specified by group, there is no need for the designer to select a special pipe design. Rather, the responsibility lies with the choices made by the contractor on the job. If the contractor elects to use reinforced concrete pipe, and the fill height exceeds 51 ft., a special design reinforced pipe may be specified for diameters 36 in. or less. Sec 1026 requires the manufacturer, prior to pipe fabrication, to provide design and installation details that must be reviewed by the Bridge Division for compliance with appropriate design standards.

Special design reinforced concrete pipe shall not be used when fill height exceeds 51 ft. with diameters greater than 36 in. This limit is due to installation difficulties associated with larger pipe diameters with the potential for problems increasing under deep fills.

750.7.7.5 Payment for Bedding

There is no direct payment or bid item for any bedding category; however, when an unsuitable bedding material exists, such as rock, payment for a specific bedding material needed for the installation type specified will be included in the Class 3 excavation.

750.7.8 Fill Settlements

Fill settlements can seriously affect concrete box structures by opening joints and cracks sufficiently to allow the fill around the culvert to infiltrate into the culvert, thereby creating voids which can cause the roadbed to fail. In areas subject to large settlements, other structure types are considered or the box culvert is designed to withstand the settlement. This requires special box culvert designs and where box culverts are to be so designed, Bridge Division is furnished with full information, including culvert sections, grades, and anticipated settlement. Box culverts with special collars around joints have been successfully designed and used in areas subject to large fill settlements. Since such structures are expensive, it is sometimes more economical to use other structure types, such as flexible pipe.

750.7.9 Camber in Culverts

Camber, as used in culvert design, is defined as the distance the central portion of crossroad structures is constructed above final flowline grade to compensate for anticipated settlement. Typical details for cambering culverts are shown on Standard Plan 726.30. A structure designed with proper camber will settle to near flowline grade and elevation when it reaches final settlement. All culverts, except those on non-yielding foundations, are cambered at a minimum rate of 0.01 ft/ft of overfill. Cambers of 0.1 ft. or less are not shown on plans. Where the fill settlement is known, culverts are designed with a camber equal to the anticipated settlement. The camber is shown on the culvert section at the roadbed shoulders by amount and flowline elevation.

750.7.10 Culvert Extensions

All culvert extensions, both boxes and pipes, are extended with structures meeting current design requirements and standards, regardless of the type of standard of the existing structure. Pipe collars, as detailed on Standard Plan 604.40, are used to connect different types of pipe, and concrete pipe to concrete pipe. For extension of box culverts EPG 751.8.3.4 Miscellaneous, Culvert Extensions. Additional fills on existing box culverts may require a structural analysis of the existing structure by the Bridge Division. If so, Bridge Division is furnished a print of the completed culvert section and the standard to which the existing structure was designed, if known, for their use in making the analysis.

The unit cost for pipe or box extensions is typically greater than the unit cost for new construction of pipe or box culverts.

For floodplain development permit requirements, see EPG 748.9.3.3 National Flood Insurance Program (NFIP) - Culvert Extensions for structures designed by Bridge or EPG 127.9 Floodplain Management and the Regulatory Floodway for roadway culverts.

750.7.11 Overfill Heights

750.7.11.1 Minimum Fill Heights

The minimum allowable fill or cover for all structures is 1 ft. at the outside shoulder line, (refer to EPG 751.1.2.8.3.3 Box Culverts, Roadway Fill for details of warping fill over exposed portions of box culverts), with the following exceptions:

- The minimum fill for structural-plate pipe structures is tabulated in Allowable Overfills for Structural Plate Pipe.

- The minimum clearance from the top of pipe structures to the bottom of the aggregate base material is 6 inches.

- The minimum fill for box culverts at the outside shoulder line is the greater of 1 ft. or the pavement thickness plus 4 ½ in. of aggregate base material, with a minimum of 4 ½ in. of aggregate base material under all pavement. Exceptions are special box culverts designed to carry traffic on the top slab.

- For roadways with an ADT ≤ 1700, the minimum fill at the shoulder on the inside of superelevated curves is 18 inches.

- Minimum fill heights for vitrified clay pipe (extra strength) are 4 ft. for the 8 to 21 in. diameters and 3 ft. for the 24 to 36 in. diameters.

Overfill heights which are less than those indicated as allowable for any one pipe type are not considered as justification for the elimination of specifying pipe types by "Group" provided other criteria are satisfactory.

750.7.11.2 Design Fill Heights

For standard concrete box culverts if design fill is between tabulated design fills, use the next greater tabulated design fill, except for design fills between 2 ft. and 4 feet. For design fills between 2 ft. and 4 ft. use the greater member thickness, area of reinforcement and bar dimensions from the 2 ft. and 4 ft. tabulated design fills. For pipe culverts where the fill height is between values tabulated for design, the design fill height is taken to the next increment requiring the higher design. Pipe culverts are designed throughout their length for the maximum design condition except in the case of structural plate pipe.

A single fill height, representing the maximum height of fill over the culvert, can be used for most box culverts. Additional fill heights may be used for longer culverts, as described in EPG 751.8.2.2 Design Fill. Generally, no more than two or three fill heights should be required. When multiple fill heights are used, consideration should be given to the potential for future widening of the roadbed.

Design fill heights for all pipe culverts specified by "Group" are shown on the "B" sheets. The allowable overfill heights for corrugated metal pipe-arches and structural plate pipes are tabulated in Allowable Overfills for Corrugated Metal Pipe-Arches and Allowable Overfills for Structural Plate Pipe. These overfill heights indicate both a minimum and a maximum, neither of which should be exceeded. If overfill heights exceed the range shown, a different gage may be necessary and a special design is requested from the Central Office. A special design is also requested for pipe-arches of a size not listed in Allowable Overfills for Corrugated Metal Pipe-Arches. If a different gage is necessary, the plans specify the gage required. Where overfill heights are greater than shown in the figure, consideration should be given to round pipe. The gage for structural plate pipe is specified on the plans and may be changed throughout the length of the structure, where economically feasible, dependent on the fill heights in accordance with Allowable Overfills for Structural Plate Pipe.

750.7.11.3 Maximum Fill Heights

750.7.11.3.1 Box Culverts

For design fill heights of less than 1 ft. or exceeding 50 ft., a special design request is made to Bridge Division. A plat showing the culvert location and a cross section at the culvert location should be provided with the request. A special sheet with structural details will be returned to the district. Input on pay item quantities will also be provided.

750.7.11.3.2 Pipes

Design overfill heights which are in excess of those indicated as allowable for any one pipe type are not considered as justification for the elimination of specifying pipe types by "Group" provided other criteria are satisfactory.

For fill heights exceeding the values tabulated on Std. Plan 726.30 for circular reinforced concrete pipe diameters 36 in. or less, the contractor has the option to supply a special design reinforced concrete pipe in accordance with Sec 1026.

750.7.12 Culvert Grades

Crossroad drainage structures are usually placed parallel to the natural stream slope or the ditch slope in which the culvert is being placed. The invert of most culverts with a width or diameter larger than 48 in. are required to be embedded a minimum of 1 ft. below the natural ditch grade due to environmental requirements. Culverts that are not embedded should have a minimum slope of 0.3% to reduce the chances of an adverse slope being created if there is any settlement at the inlet. 0% slopes may be used in special cases or where flow may occur in either direction. Culverts with slopes greater than 10% or with drops more than 25’ may require special connections between culvert sections. See FHWA's Hydraulic Design of Highway Culverts – Hydraulic Design Series No. 5 (HDS-5) for additional details. Erosion may be a problem at the outlet end of culverts on steep slopes which sometimes can be reduced by breaking the slope within the culvert. Slope breaks can also be used to reduce structure excavation. Drop structures can be used at the inlet end of culverts to reduce the slope through the culvert. Drop structures are used with discretion because of the ponding upstream, and because of the unstable condition that may be created by the ponding.

Guidance about controlling slopes for storm sewers and sanitary sewers is available.

The slope for pipes for median drop inlets is broken in accordance with the requirements and details illustrated on Pipe Grades For Median Drop Inlets.

750.7.13 Culvert Lengths

Culvert lengths are determined graphically by scaling from the culvert sections. The lengths are obtained by intersection of the structure with slope lines as shown on the culvert standard plans, and as described in the following sections. Precise lengths are not computed. In questionable cases a longer length is used. Skewed slopes used for culvert sections are shown on Slopes for Skewed Culvert Sections. Intermediate values are interpolated.

750.7.13.1 Box Culverts

For additional information on culvert length, see EPG 751.1.2.8.3.2 Length. For maximum length of box culver barrels and box culvert cut sections, refer to EPG 751.8.3.1 Joints, Transverse Joints and EPG 751.8.1.3 Barrel Section Dimensions.

750.7.13.2 Pipes

The length of pipe culverts with headwalls is 2 ft. longer than the distance between headwalls. Pipe headwalls are designed on a flat grade, regardless of the grade of the pipe. The length of pipe culverts not beveled and without headwalls is the distance between the slope lines at the flowline. Corrugated metallic-coated steel pipe lengths are scaled to the next higher even foot. Other pipe lengths are scaled to the next higher 1.0 ft. The length of corrugated metallic-coated steel pipes with beveled ends is 2 ft. longer than the distance between the intersection of the slope lines and the centerline of the pipe scaled to the next higher even foot. Pipe bends and special connections are not listed as a pay item on the plans. The plans should include notes to the effect that such items are required and that their costs are included in other items. The plans include, usually on the culvert sections, sufficient dimensions and detail to fabricate pipe with bends or special connections.

750.7.14 Excavation for Structure

See EPG 206 Excavation for Structures.

750.7.15 Connections

The plans provide for connecting new structures to existing structures, and connecting different types of new structures. The plans do not include an item for the connection of pipes to existing manholes, box culverts, drop inlets or sewer pipes. The plans do include the pipe collar item for connecting different types of pipe or different sizes of pipes. Details for pipe collars are shown on Standard Plan 604.40.

750.7.16 Culvert Cleanout

Information needed to properly estimate culvert cleanout items are:

- Location of culvert by station

- Type of culvert, i.e. corrugated metal or concrete

- Length of culvert

- Size of culvert

This information should be listed for each culvert to be cleaned out on the 2B sheets under the heading "Culvert Cleanout, Estimated." This information should be obtained from existing plans; no field measurement is required.

750.7.17 Slotted Drains

Slotted drains may be used to assist in drainage across entrances or very short sections of the roadway edge. Consistent hydraulic characteristics are not available, so slotted drains should not be expected to completely drain a pavement area. Chapter 4 of the FHWA Hydraulic Engineering Circular 22, "HEC-22 Urban Drainage Design" provides guidance for the design of slotted drains. The plans provide for the contractor to select among different styles of slotted drains (See Standard Plan 604.70). The diameter of pipe and length of slotted drain are specified in the plans.