751.6 General Quantities: Difference between revisions

→751.6.2.16 Tack Coat: updated per RR3940 |

|||

| (63 intermediate revisions by 4 users not shown) | |||

| Line 3: | Line 3: | ||

===751.6.1 Index of Quantities=== | ===751.6.1 Index of Quantities=== | ||

The following list of pay items shall be used as a guide when preparing the Table of Estimated Quantities to be shown on the bridge plans. | The following list of pay items shall be used as a guide when preparing the Table of Estimated Quantities to be shown on the bridge plans. The pay items shall be listed on the plans in numerical order according to the Item Number. The Item Number is for information only and is not to be listed in the Table of Estimated Quantities. For pay items not listed, see the Review Section. For more information about pay items, see [https://modotgov.sharepoint.com/sites/CO_BR/Shared%20Documents/General/Review/Estimates/Bridge%20Pay%20Items.xlsx?d=wb7b0e56ae5e248229b684899dea463bf&csf=1&web=1&e=87pOaI Pay Items Spreadsheet (For MoDOT Bridge access only)]. | ||

'''Accuracy and Rounding''' | '''Accuracy and Rounding''' | ||

| Line 11: | Line 11: | ||

Round final calculation to the nearest unit increment given as the plan reporting accuracy and show on plans. Rounding should follow generally accepted rules and be agreeable to those responsible for estimating the final estimated quantities. | Round final calculation to the nearest unit increment given as the plan reporting accuracy and show on plans. Rounding should follow generally accepted rules and be agreeable to those responsible for estimating the final estimated quantities. | ||

{| | Items in the table below can also be found in the [https://www.modot.org/missouri-standard-specifications-highway-construction Missouri Standard Specifications for Highway Construction] | ||

{| class="wikitable" style="text-align:center" | |||

|+ | |+ | ||

|- | |- | ||

!width=" | ! width="130" | Item Number | ||

!width="120"|Plan Reporting Accuracy | ! width="120" | Plan Reporting Accuracy | ||

!width=" | ! width="150" | Units | ||

!width=" | ! width="550" | Item Description | ||

|- | |||

| colspan="4" align="left" | '''Sec 202 – Removal of Roadways and Buildings''' | |||

|- | |||

| 202-40.18 || 1 || linear foot || align="left" | Removal of Miscellaneous ACM (Non-Friable) | |||

|- | |||

| 202-40.43 || 1 || sq. foot || align="left" | Removal of Miscellaneous ACM (Non-Friable) | |||

|- | |||

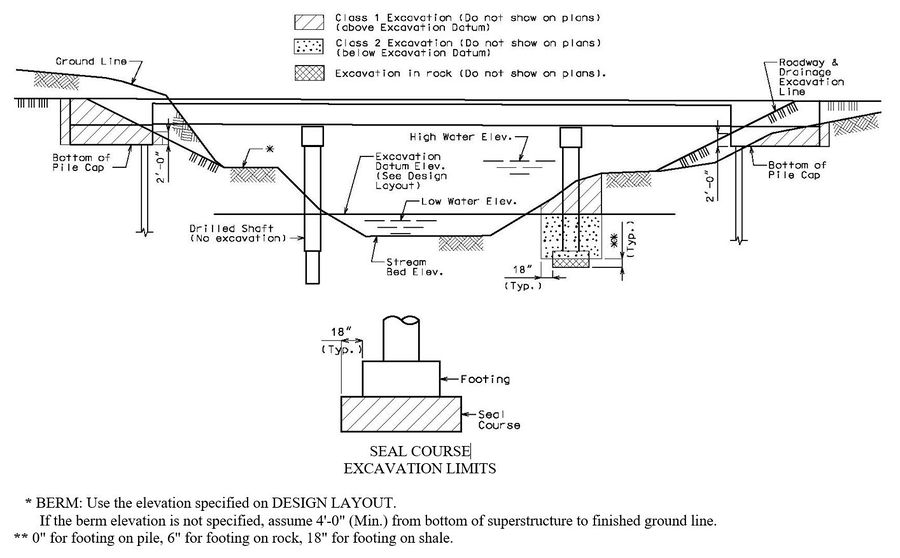

| colspan="4" align="left" | '''Sec 206 – Excavation for Structures''' | |||

|- | |||

| 206-10.00 || 5 || cu. yard || align="left" | Class 1 Excavation | |||

|- | |||

| 206-10.03 || 1 || cu. yard ||align="left"| Class 1 Excavation in Rock <i>(*)</i> | |||

|- | |||

| 206-20.00 || 1 || cu. yard ||align="left"| Class 2 Excavation | |||

|- | |||

| 206-20.03 || 1 || cu. yard ||align="left"| Class 2 Excavation in Rock <i>(*)</i> | |||

|- | |||

| 206-33.00 || 5 || cu. yard ||align="left"| Class 4 Excavation | |||

|- | |||

| 206-34.00 || 1 || cu. yard ||align="left"| Class 4 Excavation in Rock <i>(*)</i> | |||

|- | |||

| colspan="4" align="left" | * <i>Note: Use when cross-sections indicate rock will be encountered and quantity is more than 10 cu. Yard. If there is less than 10 cu. yards of total excavation in rock, no Excavation in Rock pay items should be listed in the Estimated Quantities. Excavation in rock will be paid in accordance with Sec 109. Check with Project Manager when computing this item</i>. | |||

|- | |||

| 206-36.00 || 1 || linear foot || align="left" | Supplementary Foundation Test Holes (NX) | |||

|- | |||

| 206-36.10 || 1 || linear foot || align="left" | Supplementary Cored Holes | |||

|- | |- | ||

| | | 206-40.00 || 1 || cu. yard || align="left" | Porous Backfill | ||

| | |||

|- | |- | ||

| | | 206-55.00 || 1 || lump sum || align="left" | Temporary Shoring | ||

|- | |- | ||

|206- | | 206-60.02 to<br/>206-60.12 || 1 || lump sum || align="left" | Cofferdams - Bent xx<br/><i>Note: Use a separate pay item for each bent. Item numbers established for only Bent 2 thru Bent 12</i>. | ||

|- | |- | ||

|206- | | 206-99.01 || 1 || lump sum || align="left" | Misc. | ||

|- | |- | ||

|206- | | 206-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

|206- | | 206-99.03 || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

|206- | | 206-99.04 || 1 || sq. foot || align="left" | Misc. | ||

|- | |- | ||

| | | 206-99.05 || 1 || sq. yard || align="left" | Misc. | ||

|- | |- | ||

| | | 206-99.07 || 0.1 || cu. yard || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 216 – Removals for Bridge Structures''' | ||

|- | |- | ||

| | | 216-05.00 || 1 || lump sum || align="left" | Removal of Bridges | ||

|- | |- | ||

| | | 216-05.01 || 1 || lump sum ||align="left" | Match Marking and Storing Superstructure | ||

|- | |- | ||

| | | 216-10.00 || 1 || sq. yard || align="left" | Scarification of Bridge Deck<br/><i>Note: Do not use with concrete wearing surface removals</i>. | ||

|- | |- | ||

| | | 216-10.01 || 1|| sq. yard || align="left" | Total Surface Hydro Demolition | ||

|- | |- | ||

| | | 216-15.00 || 1 || sq. foot || align="left" | Removal of Seal Coat or Polymer Wearing Surface<br/><i>Note: Do not use for unbonded removal</i>. | ||

|- | |- | ||

| | | 216-15.01 || 1 || sq. foot || align="left" | Removal of Asphalt Wearing Surface | ||

|- | |- | ||

| | | 216-15.02 || 1 || sq. foot || align="left" | Removal of Concrete Wearing Surface<br/><i>Note: Use for all concrete wearing surfaces</i>. | ||

|- | |- | ||

| | | 216-15.03 || 1 || sq. foot || align="left" | Removal of Existing Deck Repair<br/><i>Note: Use with Hydro demolition when required</i>. | ||

|- | |- | ||

| | | 216-20.00 || 1 || linear foot || align="left" | Removal and Storage of Existing Bridge Rail | ||

|- | |- | ||

| | | 216-25.00 || 1 || sq. foot || align="left" | Removal of Existing Bridge Deck | ||

|- | |- | ||

| | | 216-30.00 || 1 || sq. foot || align="left" | Partial Removal of Existing Bridge Deck | ||

|- | |- | ||

|216- | | 216-35.00 || 1 || lump sum || align="left" | Partial Removal of Culvert Concrete | ||

|- | |- | ||

|216- | | 216-35.01 || 1 || lump sum || align="left" | Partial Removal of Culvert-Bridge Concrete | ||

|- | |- | ||

|216- | | 216-35.02 || 1 || lump sum || align="left" | Partial Removal of Substructure Concrete | ||

|- | |- | ||

|216- | | 216-40.00 || 1 || linear foot || align="left" | Curb Removal<br/><i>Note: Use for just removal of curbs including for thrie beam installation</i>. | ||

|- | |- | ||

|216- | | 216-45.00 || 1 || linear foot || align="left" | Removal of Existing Expansion Joint & Adjacent Concrete<br/><i>Note: Also use concrete and reinforcing steel pay items for replacement of expansion joint system</i>. | ||

|- | |- | ||

|216- | | 216-50.00 || 1 || linear foot || align="left" | Removal of Existing Expansion Joint Seal or Sealant<br/><i>Note: Also use Concrete and Reinforcing Steel pay items for replacement of expansion joint system</i>. | ||

|- | |- | ||

|216- | | 216-55.00 || 1 || lump sum || align="left" | Removal of Cathodic Protection System | ||

|- | |- | ||

|216- | | 216-99.01 || 1 || lump sum || align="left" | Misc. | ||

|- | |- | ||

|216- | | 216-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

|216- | | 216-99.03 || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

|216- | | 216-99.04 || 1 || sq. foot || align="left" | Misc. | ||

|- | |- | ||

|216- | | 216-99.05 || 1 || sq. yard || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 403 – Asphaltic Concrete Pavement''' | ||

|- | |- | ||

| | | 403-10.50 || 1 || sq. yard || align="left" | Optional Asphaltic Concrete Wearing Surface (Bridges) | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 407 – Tack Coat''' | ||

|- | |- | ||

| | | 407-10.05 || 1 || gallon || align="left" | Tack Coat | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 409 – Seal Coat''' | ||

|- | |- | ||

| | | 409-10.48 || 1 || gallon || align="left" | Emulsified Asphalt, Seal Coat | ||

|- | |- | ||

| | | 409-40.01 || 1 || sq. yard || align="left" | Seal Coat Aggregate, Grade A1 | ||

|- | |- | ||

| | | 409-40.11 || 1 || sq. yard || align="left" | Seal Coat Aggregate, Grade B1 | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 413 – Surface Treatments''' | ||

|- | |- | ||

| | | 413-33.00 || 1|| sq. yard || align="left" | Optional Ultrathin Bonded Asphalt Wearing Surface (Bridges) | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 503 – Bridge Approach Slab''' | ||

|- | |- | ||

| | | 503-10.10A || 1 || sq. yard || align="left" | Bridge Approach Slab (Major) | ||

|- | |- | ||

| | | 503-10.11A || 1 || sq. yard || align="left" | Bridge Approach Slab (Minor) | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 505 – Bridge Deck Concrete Wearing Surface''' | ||

|- | |- | ||

| | | 505-00.01 || 1 || sq. yard || align="left" | Optional Concrete Wearing Surface | ||

|- | |- | ||

| | | 505-00.02 || 1 || sq. yard || align="left" | Optional Very Early Strength Concrete Wearing Surface | ||

|- | |- | ||

|505- | | 505-00.03 || 1 || sq. yard || align="left" | Reinforced Concrete Wearing Surface | ||

|- | |- | ||

|505- | | 505-00.04 || 1 || cu. yard || align="left" | Supplementary Wearing Surface Material<br/><i>Note: Use with total surface hydro demolition to pay for monolithic deck repair</i>. | ||

|- | |- | ||

|505- | | 505-10.00 || 1 || sq. yard || align="left" | Low Slump Concrete Wearing Surface<br/><i>Note: Use with SPM or SLE approval (typically only allowed as a choice with 505-00.01)</i>. | ||

|- | |- | ||

|505- | | 505-20.00 || 1 || sq. yard || align="left" | Latex Modified Concrete Wearing Surface | ||

|- | |- | ||

| | | 505-30.00 ||1||sq. yard||align="left"| Silica Fume Concrete Wearing Surface | ||

|- | |- | ||

|505- | | 505-40.00 || 1 || sq. yard || align="left" | Latex Modified Very Early Strength Concrete Wearing Surface | ||

|- | |- | ||

| | | 505-50.00 || 1 || sq. yard || align="left" | CSA Cement Very Early Strength Concrete Wearing Surface | ||

|- | |- | ||

| | | 505-60.00 || 1 || sq. yard || align="left" | Steel Fiber Reinforced Concrete Wearing Surface | ||

|- | |- | ||

| | | 505-70.00 || 1|| sq. yard || align="left" | Polyester Polymer Concrete Wearing Surface | ||

|- | |- | ||

| | | 505-99.05 || 1 || sq. yard || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 605 - Underdrainage''' | ||

|- | |- | ||

| | | 605-20.10A || 1 || linear foot || align="left" | Structural Underdrain | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 607 - Fencing''' | ||

|- | |- | ||

|607-10. | | 607-10.50 || 1 || linear foot || align="left" | Chain-Link Fence (Retaining Walls) | ||

|- | |- | ||

|607-10. | | 607-10.54 || 1 || linear foot || align="left" | (42 in.) Property Fence (Structures) | ||

|- | |- | ||

|607-10. | | 607-10.55 || 1 || linear foot || align="left" | (60 in.) Property Fence (Structures) | ||

|- | |- | ||

|607-10. | | 607-10.56 || 1 || linear foot || align="left" | (72 in.) Property Fence (Structures) | ||

|- | |- | ||

| | | 607-10.57 || 1 || linear foot ||align="left" | (84 in.) Property Fence (Structures) | ||

|- | |- | ||

|607- | | 607-10.58 || 1 || linear foot || align="left" | (96 in.) Property Fence (Structures) | ||

|- | |- | ||

| | | 607-10.60 || 1 || linear foot || align="left" | Pedestrian Fence (Structures) | ||

|- | |- | ||

| | | 607-10.65 || 1 || linear foot ||align="left" | (60 in.) Pedestrian Fence (Structures) | ||

|- | |- | ||

| | | 607-10.66 || 1 || linear foot || align="left" | (72 in.) Pedestrian Fence (Structures) | ||

|- | |- | ||

| | | 607-10.67 || 1 || linear foot || align="left" | (96 in.) Curved Top Pedestrian Fence (Structures) | ||

|- | |- | ||

| | | 607-10.68 || 1 || linear foot || align="left" | (120 in.) Pedestrian Fence (Structures) | ||

|- | |- | ||

| | | 607-30.00 || 1 || linear foot || align="left" | (30 in.) Decorative Pedestrian Fence (Structures) | ||

|- | |- | ||

| | | 607-30.01 || 1 || linear foot || align="left" | (48 in.) Decorative Pedestrian Fence (Structures) | ||

|- | |- | ||

| | | 607-30.02|| 1 || linear foot || align="left" | (60 in.) Decorative Pedestrian Fence (Structures) | ||

|- | |- | ||

| | | 607-30.03 || 1 || linear foot || align="left" | (72 in.) Decorative Pedestrian Fence (Structures) | ||

|- | |- | ||

| | | 607-30.04 || 1 || linear foot || align="left" | (96 in.) Decorative Pedestrian Fence (Structures) | ||

|- | |- | ||

| | | 607-99.03 || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 615 – Office for Engineer''' | ||

|- | |- | ||

| | | 615-10.05 ||1||lump sum||align="left"| Water Transportation for Engineer | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 623 – Polymer Products''' | ||

|- | |- | ||

| | | 623-00.01 || 1 || sq. yard || align="left" | Optional Polymer Wearing Surface | ||

|- | |- | ||

| | | 623-30.00 || 1 || sq. yard || align="left" | Epoxy Polymer Wearing Surface | ||

|- | |- | ||

| | | 623-40.00 || 1 || cu. foot || align="left" | Polymer Concrete | ||

|- | |- | ||

| | | 623-50.00 || 1 || sq. yard || align="left" | MMA Polymer Slurry Wearing Surface | ||

|- | |- | ||

| | | 623-99.05 || 1 || sq. yard || align="left"| Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" |'''Sec 701 – Drilled Shafts''' | ||

|- | |- | ||

|701-11. | | 701-11.00 || 0.1 || linear foot || align="left" | Drilled Shafts (1 ft. 0 in. Dia.) | ||

|- | |- | ||

|701-11. | | 701-11.01 || 0.1 || linear foot || align="left" | Drilled Shafts (1 ft. 6 in. Dia.) | ||

|- | |- | ||

|701-11. | | 701-11.02 || 0.1 || linear foot || align="left" | Drilled Shafts (2 ft. 0 in. Dia.) | ||

|- | |- | ||

| | | 701-11.03 || 0.1 || linear foot || align="left" | Drilled Shafts (2 ft. 6 in. Dia.) | ||

|- | |- | ||

| | | 701-11.04 || 0.1 || linear foot || align="left" | Drilled Shafts (3 ft. 0 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.05 || 0.1 || linear foot || align="left" | Drilled Shafts (3 ft. 6 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.06 || 0.1 || linear foot || align="left" | Drilled Shafts (4 ft. 0 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.07 || 0.1 || linear foot || align="left" | Drilled Shafts (4 ft. 6 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.08 || 0.1 || linear foot || align="left" | Drilled Shafts (5 ft. 0 in. Dia.) | ||

|- | |||

| 701-11.09 || 0.1 || linear foot || align="left" | Drilled Shafts (5 ft. 6 in. Dia.) | |||

|- | |- | ||

|701- | | 701-11.10 || 0.1 || linear foot || align="left" | Drilled Shafts (6 ft. 0 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.11 || 0.1 || linear foot || align="left" | Drilled Shafts (6 ft. 6 in. Dia.) | ||

|- | |- | ||

|701-12 | | 701-11.12 || 0.1 ||linear foot || align="left" | Drilled Shafts (7 ft. 0 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.13 || 0.1 || linear foot || align="left" | Drilled Shafts (7 ft. 6 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.14 || 0.1 || linear foot || align="left" | Drilled Shafts (8 ft. 0 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.15 || 0.1 || linear foot || align="left" | Drilled Shafts (8 ft. 6 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.16 || 0.1 || linear foot || align="left" | Drilled Shafts (9 ft. 0 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.17 || 0.1 || linear foot || align="left" | Drilled Shafts (9 ft. 6 in. Dia.) | ||

|- | |- | ||

|701- | | 701-11.18 || 0.1 || linear foot || align="left" | Drilled Shafts (10 ft. 0 in. Dia.) | ||

|- | |- | ||

|701-12. | | 701-12.00 || 0.1 || linear foot||align="left" | Rock Sockets (1 ft. 0 in. Dia.) | ||

|- | |- | ||

|701-12. | | 701-12.01 || 0.1 || linear foot || align="left" | Rock Sockets (1 ft. 6 in. Dia.) | ||

|- | |- | ||

|701-12. | | 701-12.02 || 0.1 || linear foot || align="left" | Rock Sockets (2 ft. 0 in. Dia.) | ||

|- | |- | ||

|701-12. | | 701-12.03 || 0.1 || linear foot || align="left" | Rock Sockets (2 ft. 6 in. Dia.) | ||

|- | |- | ||

| | | 701-12.04 || 0.1 || linear foot || align="left" | Rock Sockets (3 ft. 0 in. Dia.) | ||

|- | |- | ||

| | | 701-12.05 || 0.1 || linear foot || align="left" | Rock Sockets (3 ft. 6 in. Dia.) | ||

|- | |- | ||

|701- | | 701-12.06 || 0.1 || linear foot || align="left" | Rock Sockets (4 ft. 0 in. Dia.) | ||

|- | |- | ||

|701- | | 701-12.07 || 0.1 || linear foot || align="left" | Rock Sockets (4 ft. 6 in. Dia.) | ||

|- | |- | ||

|701- | | 701-12.08 || 0.1 || linear foot || align="left" | Rock Sockets (5 ft. 0 in. Dia.) | ||

|- | |- | ||

| | | 701-12.09 || 0.1 || linear foot || align="left" | Rock Sockets (5 ft. 6 in. Dia.) | ||

|- | |- | ||

|701- | | 701-12.10 || 0.1 || linear foot || align="left" | Rock Sockets (6 ft. 0 in. Dia.) | ||

|- | |- | ||

|701- | | 701-12.11 || 0.1 || linear foot || align="left" | Rock Sockets (6 ft. 6 in. Dia.) | ||

|- | |- | ||

|701- | | 701-12.12 || 0.1 || linear foot || align="left" | Rock Sockets (7 ft. 0 in. Dia.) | ||

|- | |- | ||

| | | 701-12.13 || 0.1 || linear foot || align="left" | Rock Sockets (7 ft. 6 in. Dia.) | ||

|- | |- | ||

| | | 701-12.14 || 0.1 || linear foot || align="left" | Rock Sockets (8 ft. 0 in. Dia.) | ||

|- | |- | ||

| | | 701-12.15 || 0.1 || linear foot || align="left" | Rock Sockets (8 ft. 6 in. Dia.) | ||

|- | |- | ||

| | | 701-12.16 || 0.1 || linear foot || align="left" | Rock Sockets (9 ft. 0 in. Dia.) | ||

|- | |- | ||

| | | 701-12.17 || 0.1 || linear foot || align="left" | Rock Sockets (9 ft. 6 in. Dia.) | ||

|- | |- | ||

| | | 701-13.00 || 1 || each || align="left" | Video Camera Inspection | ||

|- | |- | ||

| | | 701-14.00 || 0.1 || linear foot || align="left" | Foundation Inspection Holes | ||

|- | |- | ||

| | | 701-16.00 || 1 || each || align="left" | Sonic Logging Testing | ||

|- | |- | ||

| | | 701-17.00 || 1 || each || align="left" | Drilled Shaft Load Tests | ||

|- | |- | ||

| | | 701-99.01 || 1 || lump sum || align="left" | Misc. | ||

|- | |- | ||

| | | 701-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

| | | 701-99.03 || 0.1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 702 – Load-Bearing Piles''' | ||

|- | |- | ||

|702- | | 702-10.10 || 1 || linear foot || align="left" | Structural Steel Piles (10 in.) | ||

|- | |- | ||

|702- | | 702-10.12 || 1 || linear foot || align="left" | Structural Steel Piles (12 in.) | ||

|- | |- | ||

|702- | | 702-10.14 || 1 || linear foot || align="left" | Structural Steel Piles (14 in.) | ||

|- | |- | ||

|702- | | 702-11.14 || 1 || linear foot || align="left" | Cast-In-Place Concrete Piles (14 in.) | ||

|- | |- | ||

|702- | | 702-11.16 || 1 || linear foot || align="left" | Cast-In-Place Concrete Piles (16 in.) | ||

|- | |- | ||

| | | 702-11.20 || 1 || linear foot || align="left" | Cast-In-Place Concrete Piles (20 in.) | ||

|- | |- | ||

|702- | | 702-11.24 || 1 || linear foot || align="left" | Cast-In-Place Concrete Piles (24 in.) | ||

|- | |- | ||

|702- | | 702-12.10 || 1 || linear foot || align="left" | Galvanized Structural Steel Piles (10 in.) | ||

|- | |- | ||

|702- | | 702-12.12 || 1 || linear foot || align="left" | Galvanized Structural Steel Piles (12 in.) | ||

|- | |- | ||

| | | 702-12.14 || 1 || linear foot || align="left" | Galvanized Structural Steel Piles (14 in.) | ||

|- | |- | ||

|702- | | 702-13.14 || 1 || linear foot || align="left" | Galvanized Cast-In-Place Concrete Piles (14 in.) | ||

|- | |- | ||

|702- | | 702-13.16 || 1 || linear foot || align="left" | Galvanized Cast-In-Place Concrete Piles (16 in.) | ||

|- | |- | ||

| | | 702-13.20 || 1 || linear foot || align="left" | Galvanized Cast-In-Place Concrete Piles (20 in.) | ||

|- | |- | ||

| | | 702-13.24 || 1 || linear foot || align="left" | Galvanized Cast-In-Place Concrete Piles (24 in.) | ||

|- | |- | ||

| | | 702-30.00 || 1 || linear foot || align="left" | Probe Piles | ||

|- | |- | ||

| | | 702-40.00 || 1 || each || align="left" | Static Load Test Piles | ||

|- | |- | ||

| | | 702-50.01 || 1 || each || align="left" | Dynamic Pile Testing | ||

|- | |- | ||

| | | 702-50.02 || 1 || each || align="left" | Pile Wave Analysis | ||

|- | |- | ||

| | | 702-50.03 || 1 || linear foot || align="left" | Pilot Hole | ||

|- | |- | ||

| | | 702-50.04 || 1 || each || align="left" | Dynamic Pile Restrike Testing | ||

|- | |- | ||

| | | 702-60.00 || 1 || linear foot || align="left" | Pre-Bore for Piling<br/><i>Note: Compute this to nearest foot for each hole</i>. | ||

|- | |- | ||

| | | 702-70.00 || 1 || each || align="left" | Pile Point Reinforcement | ||

|- | |- | ||

| | | 702-99.02 || 1 || each ||align="left" | Misc. | ||

|- | |- | ||

| | | 702-99.03 || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 703 – Concrete Masonry Construction''' | ||

|- | |- | ||

|703- | | 703-10.04 || 1 || sq. yard || align="left" | Diamond Grinding | ||

|- | |- | ||

|703- | | 703-10.05 || 1 || sq. yard || align="left" | Transverse Diamond Grooving | ||

|- | |- | ||

|703- | | 703-20.02 || 0.1 || cu. yard || align="left" | Class B Concrete (Misc) | ||

|- | |- | ||

|703- | | 703-20.03 || 0.1 || cu. yard || align="left" | Class B Concrete (Substructure) | ||

|- | |- | ||

|703- | | 703-20.09 || 0.1 || cu. yard || align="left" | Class B Concrete (Retaining Walls) | ||

|- | |- | ||

|703- | | 703-20.25 || 1 || each || align="left" | Deadman Anchorage Assembly | ||

|- | |- | ||

|703- | | 703-30.01 || 0.1 || cu. yard || align="left" | Seal Concrete | ||

|- | |- | ||

|703- | | 703-30.09 || 1 || lump sum || align="left" | Aesthetic Concrete Stain | ||

|- | |- | ||

|703- | | 703-30.13 || 1 || sq. yard || align="left" | Penetrating Concrete Sealer | ||

|- | |- | ||

| | | 703-40.01 || 0.1 || cu. yard || align="left" | Class B-1 Concrete | ||

|- | |- | ||

|703- | | 703-40.02 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Superstructure on Steel and Concrete) | ||

|- | |- | ||

|703- | | 703-40.03 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Substructure) | ||

|- | |- | ||

|703- | | 703-40.04 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Superstructure on Steel) | ||

|- | |- | ||

|703- | | 703-40.05 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Superstructure Voided Slabs) | ||

|- | |- | ||

|703- | | 703-40.06 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Superstructure Concrete Box Girder) | ||

|- | |- | ||

|703- | | 703-40.07 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Superstructure Concrete Tee Girder) | ||

|- | |- | ||

| | | 703-40.08 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Superstructure Solid Slab) | ||

|- | |- | ||

|703- | | 703-40.09 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Retaining Walls) | ||

|- | |- | ||

|703- | | 703-40.10 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Superstructure Concrete on I-Girder) | ||

|- | |- | ||

|703- | | 703-40.20 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Superstructure) | ||

|- | |- | ||

| | | 703-40.30 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Barriers) | ||

|- | |- | ||

|703- | | 703-40.40 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Culverts-Bridge) | ||

|- | |- | ||

|703- | | 703-40.41 || 0.1 || cu. yard || align="left" | Class B-1 Concrete (Culverts) | ||

|- | |- | ||

|703-42. | | 703-42.02 || 0.1 || cu. yard || align="left" | Class B-2 Concrete (Superstructure on Steel and Concrete) | ||

|- | |- | ||

|703-42. | | 703-42.04 || 0.1 || cu. yard || align="left" | Class B-2 Concrete (Superstructure on Steel) | ||

|- | |- | ||

|703-42. | | 703-42.05 || 0.1 || cu. yard || align="left" | Class B-2 Concrete (Superstructure Voided Slabs) | ||

|- | |- | ||

|703-42. | | 703-42.06 || 0.1 || cu. yard || align="left" | Class B-2 Concrete (Superstructure Concrete Box Girder) | ||

|- | |- | ||

|703-42. | | 703-42.07 || 0.1 || cu. yard || align="left" | Class B-2 Concrete (Superstructure Concrete Tee Girder) | ||

|- | |- | ||

|703- | | 703-42.08 || 0.1 || cu. yard || align="left" | Class B-2 Concrete (Superstructure Solid Slab) | ||

|- | |- | ||

|703- | | 703-42.10 || 0.1 || cu. yard || align="left" | Class B-2 Concrete (Superstructure Concrete on I Girder) | ||

|- | |- | ||

|703- | | 703-42.11 || 0.1 || cu. yard || align="left" | Class B-2 Concrete (Superstructure Concrete on Box Girder) | ||

|- | |- | ||

|703- | | 703-42.12 || 1 || sq. yard || align="left" | Slab on Steel | ||

|- | |- | ||

|703- | | 703-42.13 || 1 || sq. yard || align="left" | Slab on Concrete I-Girder | ||

|- | |- | ||

|703- | | 703-42.14 || 0.1 || cu. yard || align="left" | Class B-2 Concrete | ||

|- | |- | ||

|703- | | 703-42.15 || 1 || linear foot || align="left" | Type B Barrier | ||

|- | |- | ||

|703- | | 703-42.16 || 1 || linear foot || align="left" | Type H Barrier | ||

|- | |- | ||

|703- | | 703-42.18 || 1 || sq. yard || align="left" | Slab on Concrete Bulb-Tee Girder | ||

|- | |- | ||

|703- | | 703-42.19A || 1 || linear foot || align="left" | Type D Barrier | ||

|- | |- | ||

|703- | | 703-42.20 || 1 || sq. yard || align="left" | Slab on Semi-Deep Abutment | ||

|- | |- | ||

|703- | | 703-42.21 || 1 || sq. yard || align="left" | Slab on Concrete NU-Girder | ||

|- | |- | ||

| | | 703-42.22 || 1 || sq. yard || align="left" | Slab on Concrete Beam<br/><i>Note: For spread box beams and spread voided slab beams</i>. | ||

|- | |- | ||

| | | 703-42.26 || 1 || sq. yard || align="left" | Slab on Concrete Adjacent Beam<br><i>Note: For double-tee girders and when specified on the Design Layout for solid slab beams, adjacent box beams and adjacent voided slab beams</i>. | ||

|- | |- | ||

|703- | | 703-42.30 || 0.1 || cu. yard || align="left" | Class B-2 Concrete (Post-Tensioned Wearing Surface) | ||

|- | |- | ||

|703- | | 703-42.31 || 1 || sq. yard || align="left" | Slab on Steel (with Transparent Forms) | ||

|- | |- | ||

|703- | | 703-42.32 || 1 || sq. yard || align="left" | Slab on Concrete I-Girder (with Transparent Forms) | ||

|- | |- | ||

|703- | | 703-42.33 || 1 || sq. yard || align="left" | Slab on Concrete Bulb-Tee Girder (with Transparent Forms) | ||

|- | |- | ||

|703- | | 703-42.34 || 1 || sq. yard || align="left" | Slab on Concrete NU-Girder (with Transparent Forms) | ||

|- | |- | ||

| | | 703-42.35 || 1 || sq. yard || align="left" | Slab on Concrete Beam (with Transparent Forms) | ||

|- | |- | ||

| | | 703-44.10 || 1 || linear foot || align="left" | Type A Barrier | ||

|- | |- | ||

| | | 703-44.11 || 1 || linear foot || align="left" | Type C Barrier | ||

|- | |- | ||

| | | 703-44.12 || 1 || linear foot || align="left" | Type A Barrier Transition | ||

|- | |- | ||

| | | 703-44.13 || 1 || linear foot || align="left" | Type C Barrier Transition | ||

|- | |- | ||

| | | 703-44.20 || 1 || sq. foot || align="left" | Raised Median Barrier | ||

|- | |- | ||

| | | 703-44.30 || 1 || sq. foot || align="left" | Sidewalk (Bridges) | ||

|- | |- | ||

| | | 703-45.35 || 1 || linear foot || align="left" | Curb Modification | ||

|- | |- | ||

| | | 703-46.00 || 1 || linear foot || align="left" | Curb Blockout | ||

|- | |- | ||

| | | 703-46.10 || 1 || linear foot || align="left" |Corral Curb | ||

|- | |- | ||

| | | 703-46.20 || 1 || sq. yard || align="left" | Form Liners | ||

|- | |||

| 703-46.30 || 1 || linear foot || align="left" | Concrete Curb (Bridge Rail) | |||

|- | |- | ||

| | | 703-60.00A || 0.1 || cu. yard || align="left" | Class A-1 Concrete | ||

|- | |- | ||

| | | 703-99.01 || 1 || lump sum || align="left" | Misc. | ||

|- | |- | ||

| | | 703-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

| | | 703-99.03 || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

| | | 703-99.04 || 1 || sq. foot || align="left" | Misc. | ||

|- | |- | ||

| | | 703-99.05 || 1 || sq. yard || align="left" | Misc. | ||

|- | |- | ||

| | | 703-99.07 || 0.1 || cu. yard || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 704 – Concrete Masonry Repair''' | ||

|- | |- | ||

|704- | | 704-01.01 || 1 || sq. foot || align="left" | Substructure Repair (Formed) | ||

|- | |- | ||

|704- | | 704-01.02 || 1 || sq. foot || align="left" | Substructure Repair (Unformed) | ||

|- | |- | ||

|704- | | 704-01.03 || 1 || sq. foot || align="left" | Superstructure Repair (Unformed) | ||

|- | |- | ||

|704- | | 704-01.04 || 50* || sq. foot || align="left" | Half-Sole Repair | ||

|- | |- | ||

|704- | | 704-01.06 || 50* || sq. foot || align="left" | Full Depth Repair | ||

|- | |- | ||

| | | 704-01.07 || 1 || linear foot || align="left" | Slab Edge Repair (Bridges) | ||

|- | |- | ||

| | | 704-01.08 || 50* || sq. foot || align="left" | Modified Deck Repair | ||

|- | |- | ||

| | | 704-01.10 || 1 || linear foot || align="left" | Epoxy Pressure Injecting | ||

|- | |- | ||

| | |704-01.11||1||each||align="left"|Deck Girder End Repair | ||

|- | |||

|704-01.12||50*||sq. foot||align="left"|Deck Repair with Void Tube Replacement | |||

|- | |- | ||

| | |704-01.13||1||sq. foot||align="left"|Cleaning and Epoxy Coating | ||

|- | |- | ||

| | | colspan="3" | || align="left" | *<i>Note: Round quantity up to nearest multiple of 50 sq. ft</i>. | ||

|- | |- | ||

| | | 704-01.63 || 1 || sq. yard || align="left" | Concrete Crack Filler | ||

|- | |- | ||

| | | 704-01.64 || 1 || sq. foot || align="left" | Fiber Reinforced Polymer Wrap | ||

|- | |- | ||

| | | 704-99.01 || 1 || lump sum || align="left" | Misc. | ||

|- | |- | ||

| | | 704-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

| | | 704-99.03 || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

| | | 704-99.04 || 1 || sq. foot || align="left" | Misc. | ||

|- | |- | ||

| | | 704-99.05 || 1 || sq. yard || align="left" | Misc. | ||

|- | |- | ||

| | | 704-99.07 || 0.1 || cu. yard || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 705 – Prestressed Concrete Members for Bridges''' | ||

|- | |- | ||

|705-60. | | 705-60.00 || 1 || linear foot || align="left" | Type 2 (32 in.), Prestressed Concrete I-Girder | ||

|- | |- | ||

|705-60. | | 705-60.01 || 1 || linear foot || align="left" | Type 3 (39 in.), Prestressed Concrete I-Girder | ||

|- | |- | ||

|705-60. | | 705-60.02 || 1 || linear foot || align="left" | Type 4 (45 in.), Prestressed Concrete I-Girder | ||

|- | |- | ||

|705-60. | | 705-60.03 || 1 || linear foot || align="left" | Type 6 (54 in.), Prestressed Concrete I-Girder | ||

|- | |- | ||

|705-60. | | 705-60.10 || 1 || linear foot || align="left" | Type 8 (63 in.), Prestressed Concrete Bulb-Tee Girder | ||

|- | |- | ||

|705-60. | | 705-60.11 || 1 ||linear foot || align="left" | Type 7 (72 in.), Prestressed Concrete Bulb-Tee Girder | ||

|- | |- | ||

|705-60. | | 705-60.21 || 1 || linear foot || align="left" | NU 35, Prestressed Concrete NU-Girder | ||

|- | |- | ||

|705-60. | | 705-60.22 || 1 || linear foot || align="left" | NU 43, Prestressed Concrete NU-Girder | ||

|- | |- | ||

|705-60. | | 705-60.23 || 1 || linear foot || align="left" | NU 53, Prestressed Concrete NU-Girder | ||

|- | |- | ||

|705-60. | | 705-60.24 || 1 || linear foot || align="left" | NU 63, Prestressed Concrete NU-Girder | ||

|- | |- | ||

|705-60. | | 705-60.25 || 1 || linear foot || align="left" | NU 70, Prestressed Concrete NU-Girder | ||

|- | |- | ||

|705-60. | | 705-60.26 || 1 || linear foot || align="left" | NU 78, Prestressed Concrete NU-Girder | ||

|- | |- | ||

|705-60. | | 705-60.30 || 1 || linear foot || align="left" | 11 in., Prestressed Concrete Solid Slab Beam | ||

|- | |- | ||

|705-60. | | 705-60.40A || 1 || linear foot || align="left" | 15 in., Prestressed Concrete Spread Voided Slab Beam | ||

|- | |- | ||

|705-60. | | 705-60.42A || 1 || linear foot || align="left" | 18 in., Prestressed Concrete Spread Voided Slab Beam | ||

|- | |- | ||

|705-60. | | 705-60.43A || 1 || linear foot || align="left" | 21 in., Prestressed Concrete Spread Voided Slab Beam | ||

|- | |- | ||

|705-60. | | 705-60.45 || 1 || linear foot || align="left" | 15 in., Prestressed Concrete Adjacent Voided Slab Beam | ||

|- | |- | ||

|705-60. | | 705-60.47 || 1 || linear foot || align="left" | 18 in., Prestressed Concrete Adjacent Voided Slab Beam | ||

|- | |- | ||

| | | 705-60.48 || 1 || linear foot || align="left" | 21 in., Prestressed Concrete Adjacent Voided Slab Beam | ||

|- | |- | ||

| | | 705-60.49 || 1 || linear foot || align="left" | 21 in., Prestressed Concrete Spread Box Beam | ||

|- | |- | ||

|705- | | 705-60.50A || 1 || linear foot || align="left" | 27 in., Prestressed Concrete Spread Box Beam | ||

|- | |- | ||

|705- | | 705-60.51A || 1 || linear foot || align="left" | 33 in., Prestressed Concrete Spread Box Beam | ||

|- | |- | ||

|705- | | 705-60.52A || 1 || linear foot || align="left" | 39 in., Prestressed Concrete Spread Box Beam | ||

|- | |- | ||

|705- | | 705-60.53A || 1 || linear foot || align="left" | 42 in., Prestressed Concrete Spread Box Beam | ||

|- | |- | ||

| | | 705-60.54 || 1 || linear foot || align="left" | 21 in., Prestressed Concrete Adjacent Box Beam | ||

|- | |- | ||

| | | 705-60.55 || 1 || linear foot || align="left" | 27 in., Prestressed Concrete Adjacent Box Beam | ||

|- | |- | ||

| | | 705-60.56 || 1 || linear foot || align="left" | 33 in., Prestressed Concrete Adjacent Box Beam | ||

|- | |- | ||

| | | 705-60.57 || 1 || linear foot || align="left" | 39 in., Prestressed Concrete Adjacent Box Beam | ||

|- | |- | ||

| | | 705-60.58 || 1 || linear foot || align="left" | 42 in., Prestressed Concrete Adjacent Box Beam | ||

|- | |- | ||

| | | 705-60.60 || 1 || linear foot || align="left" | 16 in., Prestressed Concrete Double-Tee Girder | ||

|- | |- | ||

| | | 705-60.61 || 1 || linear foot || align="left" | 22 in., Prestressed Concrete Double-Tee Girder | ||

|- | |- | ||

| | | 705-60.62 || 1 || linear foot || align="left" | 30 in., Prestressed Concrete Double-Tee Girder | ||

|- | |- | ||

| | | 705-60.65 || 1 || linear foot || align="left" | 17 in., Prestressed Concrete Spread Box Beam | ||

|- | |- | ||

| | | 705-60.66 || 1 || linear foot || align="left" | 17 in., Prestressed Concrete Adjacent Box Beam | ||

|- | |- | ||

| | | 705-99.01 || 1 || lump sum || align="left" | Misc. | ||

|- | |- | ||

| | | 705-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

| | | 705-99.03 || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

| | | 705-99.04 || 1 || sq. foot || align="left" | Misc. | ||

|- | |- | ||

| | | 705-99.05 || 1 || sq. yard || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 706 – Reinforcing Steel for Concrete Structures''' | ||

|- | |- | ||

| | | 706-10.00 || 10 || pound || align="left" | Reinforcing Steel | ||

|- | |- | ||

| | | 706-10.20 || 10 || pound || align="left" | Reinforcing Steel (Culverts-Bridge) | ||

|- | |- | ||

| | | 706-10.30 || 10 || pound || align="left" | Reinforcing Steel (Culverts) | ||

|- | |- | ||

| | | 706-10.40 || 10 || pound || align="left" | Reinforcing Steel (Retaining Wall) | ||

|- | |- | ||

| | | 706-10.60 || 10 || pound || align="left"|Reinforcing Steel (Bridges) | ||

|- | |- | ||

| | | 706-10.70 || 1 || each || align="left" | Mechanical Bar Splice<br/><i>Note: Use when the total number of mechanical bar splices on a set of plans is 50 or greater not including any required in the approach slabs</i>. | ||

|- | |- | ||

| | | 706-99.11 || 10 || pound || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 707 – Conduit System on Structure''' | ||

|- | |- | ||

| | | 707-10.00 || 1 || lump sum || align="left" | Conduit System on Structure | ||

|- | |- | ||

| | | 707-10.30 || 1 || lump sum || align="left" | Conduit System on Structure (Telephone) | ||

|- | |- | ||

| | | 707-10.40 || 1 || lump sum || align="left" | Cathodic Protection System | ||

|- | |- | ||

| | | 707-99.01 || 1 || lump sum || align="left" | Misc. | ||

|- | |- | ||

| | | 707-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 710 – Epoxy Coated Reinforcing Steel''' | ||

|- | |- | ||

| | | 710-10.00 || 10 || pound || align="left" | Reinforcing Steel (Epoxy Coated) | ||

|- | |- | ||

| | | 710-99.11 || 10 || pound || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 711 – Protective Coatings for Exposed Concrete Surfaces''' | ||

|- | |- | ||

| | | 711-01.00 || 1 || lump sum || align="left" | Protective Coating – Concrete Bents and Piers (Urethane) <i>Note: Tar appearance</i> | ||

|- | |- | ||

| | | 711-02.00 || 1 || lump sum ||align="left" | Protective Coating – Concrete Bents and Piers (Epoxy) <i>Note: Clear appearance</i> | ||

|- | |- | ||

| | | 711-03.00 || 1 || lump sum || align="left" | Concrete and Masonry Protection System | ||

|- | |- | ||

| | | 711-04.00 || 1 || lump sum || align="left" | Sacrificial Graffiti Protection System | ||

|- | |- | ||

| | | 711-05.00 || 1 || lump sum || align="left" | Temporary Coating – Concrete Bents and Piers (Weathering Steel) | ||

|- | |- | ||

| | | 711-10.00 || 1 || sq. yard || align="left" | Waterproofing | ||

|- | |- | ||

| | | 711-10.01 || 1 || sq. yard || align="left" | Waterproofing Membrane | ||

|- | |- | ||

| | | 711-99.01 || 1 || lump sum || align="left" | Misc. | ||

|- | |- | ||

| | | 711-99.04 || 1 || sq. foot || align="left" | Misc. | ||

|- | |- | ||

| | | 711-99.05 || 1 || sq. yard || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 712 – Structural Steel Construction''' | ||

|- | |- | ||

| | | 712-09.00 || 1 || linear foot || align="left" | Expansion Device (Finger Plate) | ||

|- | |- | ||

|712- | | 712-09.15 || 1 || linear foot || align="left" | Expansion Device (Flat Plate) | ||

|- | |- | ||

|712- | | 712-10.00 || 10 || pound || align="left" | Fabricated Structural Carbon Steel (Misc.) | ||

|- | |- | ||

|712- | | 712-10.10 || 10 || pound || align="left" | Fabricated Structural Carbon Steel (I-Beam) | ||

|- | |- | ||

| | | 712-10.20 || 10 || pound || align="left" | Fabricated Structural Carbon Steel (Plate Girder) | ||

|- | |- | ||

|712- | | 712-10.30 || 10 || pound || align="left" | Fabricated Structural Carbon Steel (Trusses) | ||

|- | |- | ||

|712- | | 712-10.40 || 10 || pound || align="left" | Fabricated Structural Carbon Steel (Concrete) | ||

|- | |- | ||

| | | 712-10.50 || 10 || pound || align="left" | Fabricated Structural Carbon Steel (Box Girder) | ||

|- | |- | ||

|712- | | 712-10.60 || 1 || lump sum || align="left" | Fabricated Sign Support Brackets | ||

|- | |- | ||

|712-11. | | 712-11.00 || 10 ||pound || align="left" | Fabricated Structural Low Alloy Steel (Misc.) | ||

|- | |- | ||

|712-11. | | 712-11.11 || 10 || pound || align="left" | Fabricated Structural Low Alloy Steel (I-Beam) A709, Grade 50 | ||

|- | |- | ||

| | | 712-11.13 || 10 || pound || align="left" | Fabricated Structural Low Alloy Steel (I-Beam) A709, Grade 50W | ||

|- | |- | ||

| | | 712-11.21 || 10 || pound || align="left" | Fabricated Structural Low Alloy Steel (Plate Girder) A709, Grade 50 | ||

|- | |- | ||

|712-11. | | 712-11.22 || 10 || pound || align="left" | Fabricated Structural Low Alloy Steel (Plate Girder) A709, Grade 50W | ||

|- | |- | ||

|712- | | 712-11.23 || 10 || pound || align="left" | Fabricated Structural Low Alloy Steel (Plate Girder) A709 Grade HPS70W | ||

|- | |- | ||

|712- | | 712-11.24 || 10 || pound || align="left" | Fabricated Structural Low Alloy Steel (Plate Girder) A709 Grade HPS50W | ||

|- | |- | ||

| | | 712-11.30 || 10 || pound || align="left" | Fabricated Structural Low Alloy Steel (Trusses) | ||

|- | |- | ||

|712- | | 712-11.40 || 10 || pound || align="left" | Fabricated Structural Low Alloy Steel (Concrete) | ||

|- | |- | ||

|712- | | 712-11.51 || 10 || pound || align="left" | Fabricated Structural Low Alloy Steel (Box Girder) A709, Grade 50 | ||

|- | |- | ||

|712- | | 712-11.52 || 10 || pound || align="left" | Fabricated Structural Low Alloy Steel (Box Girder) A709, Grade 50W | ||

|- | |- | ||

|712- | | 712-11.59 || 1 || each || align="left" | Shear Connectors | ||

|- | |- | ||

|712- | | 712-11.60 || 1 || sq. foot || align="left" | Steel Grid Floor (Half Concrete Filled) | ||

|- | |- | ||

|712- | | 712-11.61 || 1 || sq. foot || align="left" | Steel Grid Floor (Concrete Filled) | ||

|- | |- | ||

|712- | | 712-12.50 || 1 || lump sum || align="left" | Strengthening Existing Beams | ||

|- | |- | ||

|712- | | 712-12.51 || 1 || each || align="left" | Hinge Modification | ||

|- | |- | ||

|712- | | 712-13.00 || 10 || pound || align="left" | Fabricated Structural Steel Bearings | ||

|- | |- | ||

|712- | | 712-20.00 || 10 || pound || align="left" | Carbon Steel Castings | ||

|- | |- | ||

|712- | | 712-22.00 || 10 || pound || align="left" | Gray Iron Castings | ||

|- | |- | ||

|712- | | 712-23.00 || 1 || linear foot || align="left" | Bridge Rail (Two Tube Structural Steel) | ||

|- | |- | ||

|712- | | 712-30.00 || 1 || each || align="left" | Steel Bar Dam | ||

|- | |- | ||

|712- | | 712-31.00 || 1 || each || align="left" | Cleaning and Coating Existing Bearings | ||

|- | |- | ||

|712- | | 712-31.10 || 1 || each || align="left" | Bearing Removal for Inspection | ||

|- | |- | ||

| | | 712-31.15 || 1 || each || align="left" | Surface Finishing Bearing Rocker | ||

|- | |- | ||

|712- | | 712-31.20 || 1 || each || align="left" | Cleaning, Lubricating and Coating Bearing | ||

|- | |- | ||

|712- | | 712-31.30 || 1 || each || align="left" | Rehabilitate Bearing | ||

|- | |- | ||

|712- | | 712-31.40 || 10 || pound || align="left" | New Bearing Materials | ||

|- | |- | ||

|712- | | 712-31.50 || 1 || each || align="left" | Anchor Bolt Replacement | ||

|- | |- | ||

|712- | | 712-32.00 || 1 || each || align="left" | Removing, Coating and Reinstalling Light Standards (Bridges) | ||

|- | |- | ||

| | | 712-32.10 || 1 || each || align="left" | Earthquake Restrainer Assemblies | ||

|- | |- | ||

|712- | | 712-32.50 || 1 || each || align="left" | Rivet Removal and Replacement | ||

|- | |- | ||

|712- | | 712-33.00 || 1 || lump sum || align="left" | Existing Diaphragm Connections to Flange | ||

|- | |- | ||

|712- | | 712-33.01 || 1 || each || align="left" | Steel Intermediate Diaphragm for P/S Concrete Girders | ||

|- | |- | ||

|712- | | 712-35.00 || 1 || linear foot || align="left" | Railing for Steps | ||

|- | |- | ||

|712- | | 712-36.10 || 1 || each || align="left" | Slab Drain | ||

|- | |- | ||

|712- | | 712-36.11 || 1 || each || align="left" | Slab Drain with Grate | ||

|- | |- | ||

|712- | | 712-36.20 || 1 || lump sum || align="left" | Drainage System (On Structure) | ||

|- | |- | ||

|712-51. | | 712-51.00 || 1 || lump sum || align="left" | Surface Preparation for Recoating Structural Steel | ||

|- | |- | ||

|712-51. | | 712-51.01 || 1 || lump sum || align="left" | Surface Preparation for Overcoating Structural Steel (System G) | ||

|- | |- | ||

|712-51. | | 712-51.02 || 1 || lump sum || align="left" | Surface Preparation for Applying Epoxy-Mastic Primer | ||

|- | |- | ||

| | | 712-51.09 || 1 || lump sum || align="left" | Field Application of Organic Zinc Primer | ||

|- | |- | ||

| | | 712-51.10 || 1 || lump sum || align="left" | Field Application of Inorganic Zinc Primer | ||

|- | |- | ||

|712- | | 712-51.11 || 1 || lump sum || align="left" | Intermediate Field Coat (System G) | ||

|- | |- | ||

|712- | | 712-51.12 || 1 || lump sum || align="left" | Finish Field Coat (System G) | ||

|- | |- | ||

| | | 712-51.13 || 1 || lump sum || align="left" | Intermediate Field Coat (System H) | ||

|- | |- | ||

|712- | | 712-51.14 || 1 || lump sum || align="left" | Finish Field Coat (System H) | ||

|- | |- | ||

|712- | | 712-51.15 || 1 || lump sum || align="left" | Finish Field Coat (System I) | ||

|- | |- | ||

| | | 712-52.00 || 100 || sq. foot || align="left" | Surface Preparation for Recoating Structural Steel | ||

|- | |- | ||

|712- | | 712-52.01 || 100 || sq. foot ||align="left" | Surface Preparation for Overcoating Structural Steel (System G) | ||

|- | |- | ||

| 712-52.02 || 100 ||sq. foot || align="left" | Chloride Remediation Surface Preparation | |||

|- | |- | ||

|712- | | 712-52.09 || 100 || sq. foot || align="left" | Field Application of Organic Zinc Primer | ||

|- | |- | ||

| | | 712-52.10 || 100 || sq. foot || align="left" | Field Application of Inorganic Zinc Primer | ||

|- | |- | ||

|712-53. | | 712-53.15A || 0.1 || ton || align="left" | Intermediate Field Coat (System G) | ||

|- | |- | ||

|712-53. | | 712-53.20A || 0.1 || ton || align="left" | Finish Field Coat (System G) | ||

|- | |- | ||

| | | 712-53.35A || 0.1 || ton || align="left" | Intermediate Field Coat (System H) | ||

|- | |- | ||

|712-53. | || 712-53.40A || 0.1 || ton || align="left" | Finish Field Coat (System H) | ||

|- | |- | ||

|712-53. | | 712-53.46 || 0.1 || ton || align="left" | Finish Field Coat (System I) | ||

|- | |- | ||

|712-53. | | 712-53.65A || 100 || sq. foot || align="left" | Intermediate Field Coat (System G) | ||

|- | |- | ||

| | | 712-53.70A || 100 || sq. foot || align="left" | Finish Field Coat (System G) | ||

|- | |- | ||

| | | 712-53.85A || 100 || sq. foot || align="left" | Intermediate Field Coat (System H) | ||

|- | |- | ||

|712- | | 712-53.90A || 100 ||sq. foot || align="left" | Finish Field Coat (System H) | ||

|- | |- | ||

|712- | | 712-53.96 || 100 || sq. foot || align="left" | Finish Field Coat (System I) | ||

|- | |- | ||

| | | 712-59.60 || 1 || lump sum || align="left" | Aluminum Epoxy-Mastic Primer | ||

|- | |- | ||

|712-59. | | 712-59.61 || 1 || lump sum || align="left" | Gray Epoxy-Mastic Primer | ||

|- | |- | ||

|712- | | 712-60.00 || 1 || linear foot || align="left" | Non-Destructive Testing | ||

|- | |- | ||

| | | 712-99.01 || 1 || lump sum || align="left" | Galvanizing Structural Steel | ||

|- | |- | ||

|712- | | 712-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

|712- | | 712-99.03 || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

| | | 712-99.04 || 1 || sq. foot || align="left" | Misc. | ||

|- | |- | ||

|712- | | 712-99.05 || 1 || sq. yard || align="left" | Misc. | ||

|- | |- | ||

|712- | | 712-99.10 || 0.1 || ton || align="left" | Misc. | ||

|- | |- | ||

| | | 712-99.11 || 10 || pound || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 713 – Thrie Beam for Bridge Guardrail''' | ||

|- | |- | ||

| | | 713-30.00 || 1 || linear foot || align="left" | Bridge Guardrail (W-Beam) | ||

|- | |- | ||

| | | 713-40.00 || 1 || linear foot || align="left" | Bridge Guardrail (Thrie Beam) | ||

|- | |- | ||

| | | 713-99.03A || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 715 – Vertical Drain at End Bents''' | ||

|- | |- | ||

| | | 715-10.01 || 1 || each || align="left" | Vertical Drain at End Bents | ||

|- | |- | ||

| | | 715-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 716 – Neoprene Bearings''' | ||

|- | |- | ||

| | | 716-10.00 || 1 || each || align="left" | Plain Neoprene Bearing Pad | ||

|- | |- | ||

| | | 716-10.01 || 1 || linear foot || align="left" | Plain Neoprene Bearing Pad | ||

|- | |- | ||

| | | 716-10.02 || 1 || each || align="left" | Laminated Neoprene Bearing Pad | ||

|- | |- | ||

| | | 716-10.03 || 1 || each || align="left" | Laminated Neoprene Bearing Pad (Tapered) | ||

|- | |- | ||

| | | 716-20.00 || 1 || each || align="left" | Laminated Neoprene Bearing Pad Assembly | ||

|- | |- | ||

| | | 716-30.00 || 1 || each || align="left" | Type N PTFE Bearing | ||

|- | |- | ||

|716- | | 716-40.00 || 1 || each || align="left" | POT Bearing | ||

|- | |- | ||

|716- | | 716-99.01 || 1 || lump sum || align="left" | Misc. | ||

|- | |- | ||

|716- | | 716-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

|716- | | 716-99.03 || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 717 – Flexible Joint Systems''' | ||

|- | |- | ||

| | | 717-00.01 || 1 || linear foot || align="left" | Alternate Expansion Joint System | ||

|- | |- | ||

| | | 717-10.01 || 1 || linear foot || align="left" | Preformed Compression Seal Expansion Joint System | ||

|- | |- | ||

| | | 717-10.02 || 1 || linear foot || align="left" | Preformed Compression Seal<br/><i>Note: Use for seal only, no armor</i>. | ||

|- | |- | ||

| | | 717-20.01 || 1 || linear foot || align="left" | Strip Seal Expansion Joint System | ||

|- | |- | ||

|| | | 717-20.02 || 1 || linear foot || align="left" | Strip Seal<br/><i>Note: Use for seal only, no armor</i>. | ||

|- | |- | ||

| | | 717-20.53 || 1 || linear foot || align="left" | Open Cell Foam Joint System | ||

|- | |- | ||

|717- | | 717-20.54 || 1 || linear foot || align="left" | Open Cell Foam Joint Seal<br/><i>Note: Use for seal only, no armor</i>. | ||

|- | |- | ||

|717- | | 717-30.01 || 1 || linear foot || align="left" | Silicone Expansion Joint Sealant System<br/><i>Note: See [[751.13 Expansion Devices#751.13.1.5 Silicone Seal Expansion Joint System|EPG 751.13.1.5 Silicone Seal Expansion Joint System]]</i>. | ||

|- | |- | ||

|717- | | 717-30.02 || 1 || linear foot || align="left" | Silicone Expansion Joint Sealant<br/><i>Note: See [[751.13 Expansion Devices#751.13.1.5 Silicone Seal Expansion Joint System|EPG 751.13.1.5 Silicone Seal Expansion Joint System]].<br/>Use for silicone sealant only, no armor<i>. | ||

|- | |- | ||

|717- | | 717-40.01 || 1 || linear foot || align="left" | Preformed Silicone or EPDM Expansion Joint System | ||

|- | |- | ||

|717- | | 717-40.02 || 1 || linear foot || align="left" | Preformed Silicone or EPDM Expansion Joint Seal<br/><i>Note: Use for seal only, no armor</i>. | ||

|- | |- | ||

|717- | | 717-99.03 || 1 || linear foot || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 718 – Temporary Bridge''' | ||

|- | |- | ||

| | | 718-10.10 || 1 || lump sum || align="left" | Furnishing Superstructure | ||

|- | |- | ||

| | | 718-10.11 || 1 || lump sum || align="left" | Partial Furnishing of Superstructure | ||

|- | |- | ||

| | | 718-10.20 || 1 || lump sum || align="left" | Transporting and Erecting Superstructure | ||

|- | |- | ||

|718-10. | | 718-10.30 || 1 || lump sum || align="left" | Removing and Storing Superstructure | ||

|- | |- | ||

|718- | | 718-99.01 || 1 || lump sum || align="left" | Misc. | ||

|- | |- | ||

|718- | | 718-99.02 || 1 || each || align="left" | Misc. | ||

|- | |- | ||

| | | colspan="4" align="left" | '''Sec 720 – Mechanically Stabilized Earth Wall Systems''' | ||

|- | |- | ||

| | |720-10.00 || 1 || sq. foot || align="left" | Mechanically Stabilized Earth Wall Systems | ||

|- | |- | ||

| | | 720-11.00 || 1 || sq. yard || align="left" | Form Liners for MSE Wall Systems | ||

|- | |- | ||

|720- | | 720-12.00 || 1 || cu. yard || align="left" | Select Granular Backfill for Structural Systems | ||

|- | |- | ||

|720- | | 720-13.00 || 1 || each || align="left" | Pipe Pile Spacers | ||

|- | |- | ||

|720- | | 720-14.00 || 1 || lump sum || align="left" | Temporary MSE Wall System | ||

|- | |- | ||

|720-99. | | 720-99.04 || 1 || sq. foot || align="left" | Misc. | ||

|- | |- | ||

| | | 720-99.05 || 1 || sq. yard || align="left" | Misc. | ||

|- | |- | ||

|| | | colspan="4" align="left" | '''Sec 901 – Highway Lighting''' | ||

|- | |- | ||

| | | 901-93.00 || 1 || lump sum || align="left" | Navigation Lighting System | ||

|- | |- | ||

|901-93.01||1||lump sum||align="left"|Bridge Lighting | | 901-93.01 || 1 || lump sum || align="left" | Bridge Lighting | ||

|} | |} | ||

| Line 915: | Line 945: | ||

====751.6.2.1 Weight of Bolts and Shear Connectors==== | ====751.6.2.1 Weight of Bolts and Shear Connectors==== | ||

Refer to AISC Manual of Steel Construction or ASTM | Refer to AISC Manual of Steel Construction or ASTM F3125 for weight and dimensions of high strength bolts and washers. When calculating the weight of high strength bolts in structural connections, the following simplified weights may be used. These values include the weight of a regular hex head, one heavy hex nut, one washer, and the portion of the bolt projecting beyond the grip (washer thickness + nut thickness + 1/4“). | ||

| Line 958: | Line 988: | ||

|7/8"||81||98||115||132 | |7/8"||81||98||115||132 | ||

|} | |} | ||

====751.6.2.2 Piles==== | ====751.6.2.2 Piles==== | ||

| Line 966: | Line 995: | ||

====751.6.2.3 Pre-bore for Piling==== | ====751.6.2.3 Pre-bore for Piling==== | ||

Pre-bore is required when fill exceeds five feet as described in Sec 702 or when specified on the Design Layout. Pre-bore is also required through earth plugs. Pre-bore is computed as the length of pile measured from the bottom of the pile cap or footing to the natural ground line or as directed on the Design Layout rounded to the nearest foot for each hole. | Pre-bore is required when fill exceeds five feet as described in [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=11 Sec 702] or when specified on the Design Layout. Pre-bore is also required through earth plugs. Pre-bore is computed as the length of pile measured from the bottom of the pile cap or footing to the natural ground line or as directed on the Design Layout rounded to the nearest foot for each hole. | ||

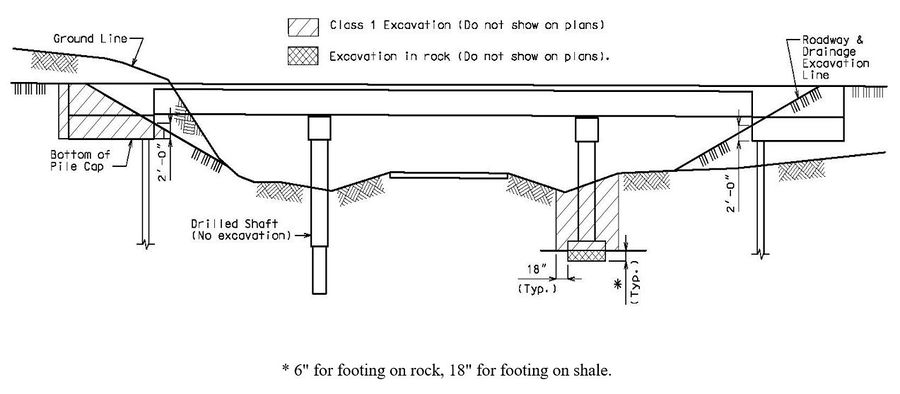

====751.6.2.4 Drilled Shafts ==== | ====751.6.2.4 Drilled Shafts ==== | ||

Drilled shafts, rock sockets and reinforcing steel quantity will be measured in accordance with Sec 701. | Drilled shafts, rock sockets and reinforcing steel quantity will be measured in accordance with Sec 701. Video camera inspection quantity will be calculated one for each drilled shaft. Foundation inspection hole quantities will be from the top of rock socket to the greater of either 10 feet or twice the diameter of the rock socket below the anticipated bottom of rock socket for each rock socket. Sonic logging testing shall be performed on all drilled shafts and rock sockets. Drilled shafts for high mast lighting will not require sonic logging testing. | ||

====751.6.2.5 Concrete==== | ====751.6.2.5 Concrete==== | ||

The volume of concrete shall be calculated to the nearest 0.1 cubic yard. | The volume of concrete shall be calculated to the nearest 0.1 cubic yard, except where reported in the table of Estimated Quantities for Slab, where concrete is rounded to the nearest whole cubic yard (see [[751.50 Standard Detailing Notes#(B3.21)|EPG 751.50, Note B3.21]]). Do not deduct for volume of concrete displaced by reinforcing steel or HP piling. When CIP piles are used, the displaced concrete volume should be deducted. | ||

====751.6.2.6 Polymer Concrete==== | ====751.6.2.6 Polymer Concrete==== | ||

| Line 987: | Line 1,016: | ||

In the rare case that there are bottom flange cover plates, it is the responsibility of the SPM or SLE to coordinate with district bridge engineer or review visual records and field inspection notes and decide if these plates need to be tested. This should include only welded cover plate ends that terminate in a tension zone. If cover plates terminate at the inflection point or past it, there is a small chance that the bottom flange cover plate welds would need to be tested. (Rarely, other areas of cover plate welds could be tested based on deteriorated conditions as reported from the field on the Structural Rehabilitation Checklist.) | In the rare case that there are bottom flange cover plates, it is the responsibility of the SPM or SLE to coordinate with district bridge engineer or review visual records and field inspection notes and decide if these plates need to be tested. This should include only welded cover plate ends that terminate in a tension zone. If cover plates terminate at the inflection point or past it, there is a small chance that the bottom flange cover plate welds would need to be tested. (Rarely, other areas of cover plate welds could be tested based on deteriorated conditions as reported from the field on the Structural Rehabilitation Checklist.) | ||

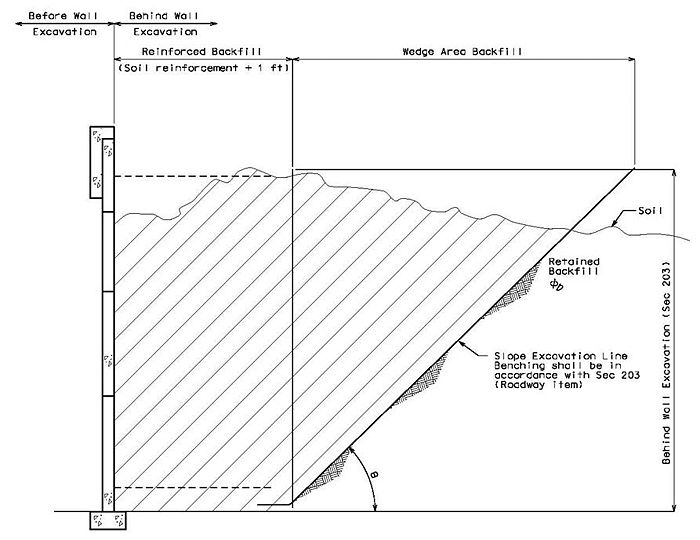

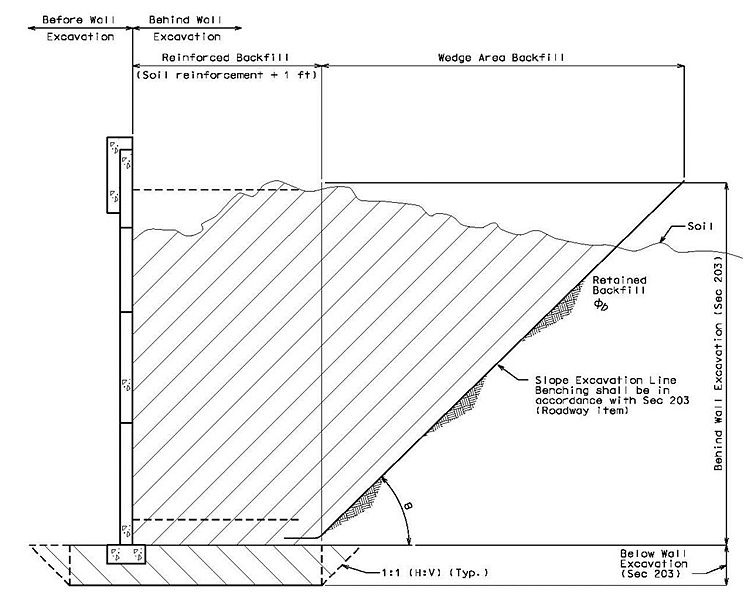

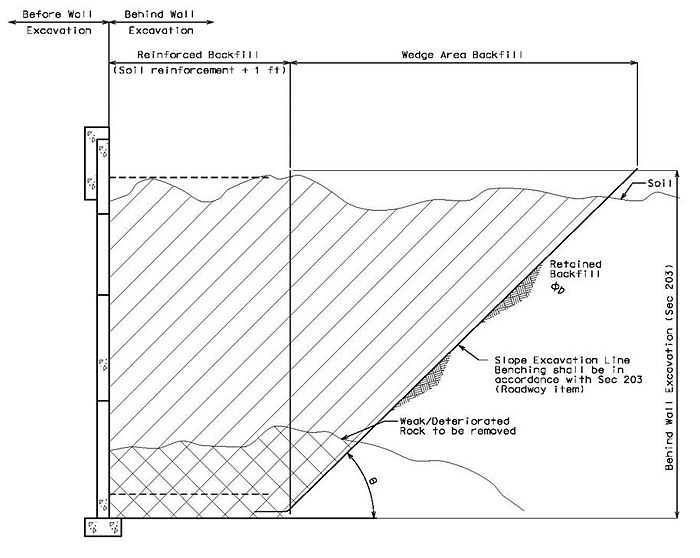

====751.6.2.8 Temporary Shoring==== | ====751.6.2.8 Temporary Shoring or Temporary MSE Wall System==== | ||

When temporary shoring is required, it shall be reported as a lump sum item on the bridge plans. | When temporary shoring or temporary MSE wall is required, it shall be reported as a lump sum item on the bridge plans. In addition, the estimated area of temporary shoring or temporary MSE wall shall be computed to the nearest square foot and recorded only in the quantity folder. Embedment of temporary shoring shall be taken as one third of the exposed height of the shoring for the purpose of estimating the shoring area. The bottom of temporary MSE wall shall be taken as the lower of the top of permanent wall levelling pad or bottom of improved foundation. For temporary shoring use 206-55.00 pay item and for temporary MSE wall system use 720-14.00 pay item ([[751.6_General_Quantities#751.6.1_Index_of_Quantities|EPG 751.6.1 Index of Quantities]]). | ||

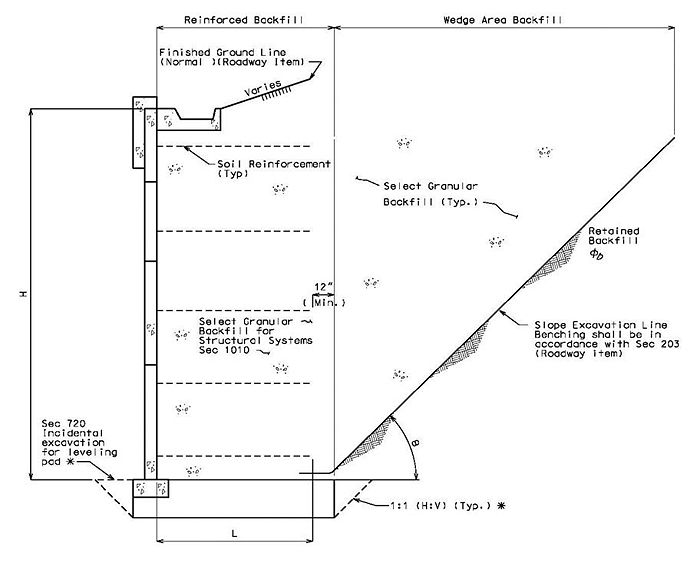

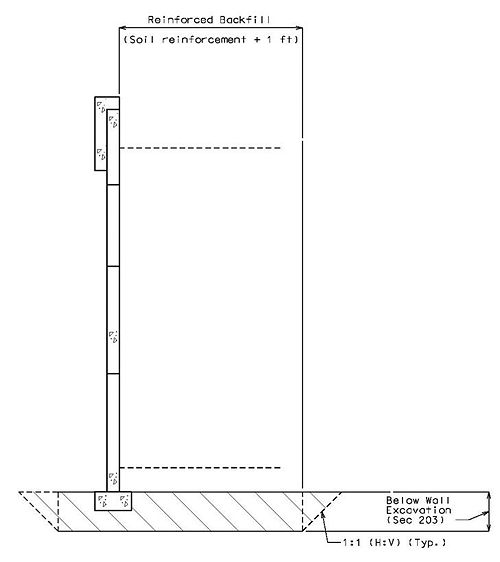

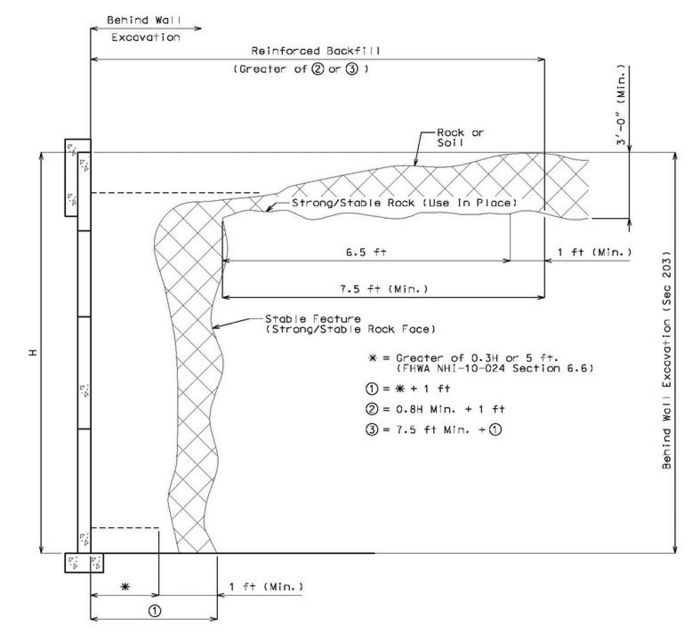

====751.6.2.9 MSE Retaining Walls==== | ====751.6.2.9 MSE Retaining Walls==== | ||

Quantities for Mechanically Stabilized Earth Wall Systems are to be calculated based on the vertical face of the wall system as shown on the plans. | Quantities for Mechanically Stabilized Earth Wall Systems are to be calculated based on the vertical face of the wall system as shown on the plans. The payment for furnishing and fabricating the concrete facing elements, excavation and installing the leveling pad, furnishing, and installing the soil reinforcement, furnishing, and placing select granular backfill for structural systems, furnishing other incidentals related to the wall system, and erecting the wall system complete-in-place, will be considered completely covered by the contract unit price for Mechanically Stabilized Earth Wall Systems per square foot. The use of the Select Granular Backfill for Structural Systems pay item will not be required. For permanent MSE wall systems use 720-10.00 pay item ([[751.6_General_Quantities#751.6.1_Index_of_Quantities|EPG 751.6.1 Index of Quantities]]). | ||

====751.6.2.10 Bridge Slabs==== | ====751.6.2.10 Bridge Slabs==== | ||

The area of concrete slabs is used in the | The gross area of concrete slabs is used in the Estimated Quantities table and shall be estimated to the nearest square yard longitudinally from end of slab to end of slab and transversely from out to out of the bridge slab. This shall include all expansion gaps within these limits. | ||

The actual volume of concrete is used in the table of slab quantities for the purpose of preparing the cost estimate and is given on the plans as an aid to the contractor. The concrete on top of the backwall at end bents for expansion joint systems shall be included in this volume (see [[751.50 Standard Detailing Notes#(B1.7)|Note B1.7]]). Concrete shall be estimated to the nearest cubic yard instead of 0.1 cubic yard due to variances and assumptions used in this estimate (see [[751.50 Standard Detailing Notes#B3c. Slabs on Steel, Concrete and Semi-Deep Abutment, and Reinforced Concrete Slab Overlays|Note B3.21]]). Reinforcing steel shall be estimated to the nearest 10 pounds. | |||

<div id="Structural Steel Protective Coatings (Nonweathering Steel)"></div> | <div id="Structural Steel Protective Coatings (Nonweathering Steel)"></div> | ||

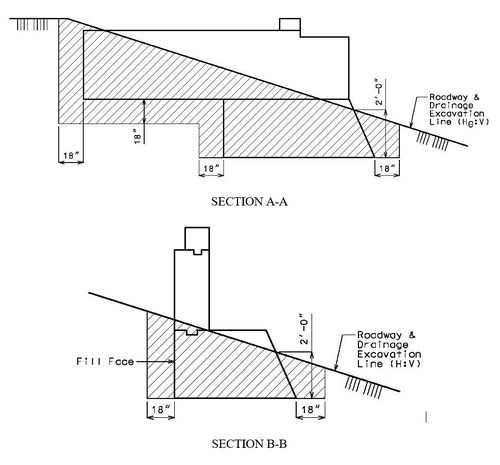

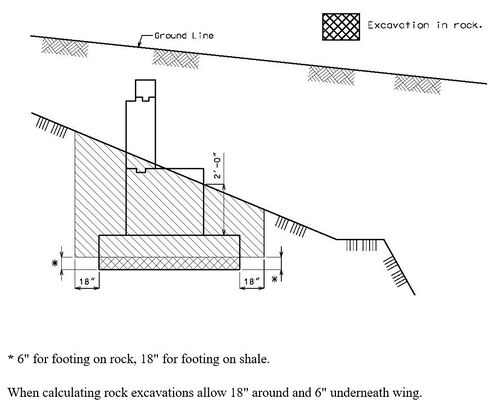

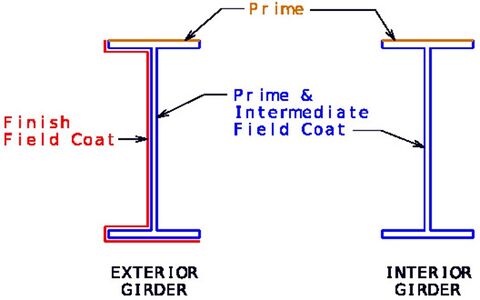

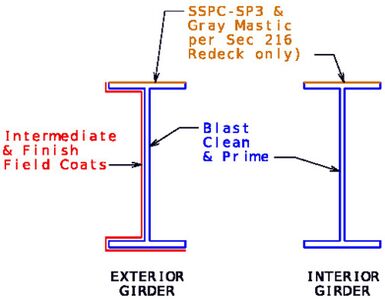

====751.6.2.11 Structural Steel Protective Coatings ( | ====751.6.2.11 Structural Steel Protective Coatings (Non-weathering Steel)==== | ||

The protective coating, as specified on the Design Layout, shall be System G, H or I with the color being gray or brown. The coating color shall be specified on the Design Layout. The following gives pay item guidelines for most bridges. | The protective coating, as specified on the Design Layout, shall be System G, H or I with the color being gray or brown. The coating color shall be specified on the Design Layout. The following gives pay item guidelines for most bridges. | ||

| Line 1,016: | Line 1,047: | ||

The surfaces of all structural steel located under expansion joints of beam and girder spans shall be field coated with intermediate and finish coats for a distance of one and a half times the girder depth, but not less than 10 feet from the center line of the joint. Within this limit, the items to be field coated shall include all surfaces of beams, girders, bearings, diaphragms, stiffeners and miscellaneous structural steel items. Areas of steel to be in contact with concrete shall not receive the field coats. The limits of the field coatings shall be masked to provide crisp, straight lines and to prevent overspray on adjacent areas. | The surfaces of all structural steel located under expansion joints of beam and girder spans shall be field coated with intermediate and finish coats for a distance of one and a half times the girder depth, but not less than 10 feet from the center line of the joint. Within this limit, the items to be field coated shall include all surfaces of beams, girders, bearings, diaphragms, stiffeners and miscellaneous structural steel items. Areas of steel to be in contact with concrete shall not receive the field coats. The limits of the field coatings shall be masked to provide crisp, straight lines and to prevent overspray on adjacent areas. | ||

<div id="When System I finish field coat"></div> | |||

When System I finish field coat is specified on the plans with System G intermediate coat, System I finish field coat quantity will be figured the same as above for the finish field coat. System G intermediate coat with System I finish field coat will be as above for the intermediate field coat except that the area of the System I finish field coat will not be included in the System G intermediate field coat area. When the plans state System I finish field coat shall be substituted for System G intermediate coat, System I finish field coat quantity will be figured for all girder surfaces as discussed above for intermediate field coat area. | |||

{| style="text-align: center; font-size:1.6em", align="center" | |||

|- | |||

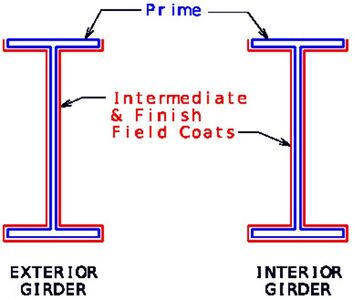

|COLSPAN="3"|<u>'''New Non-Weathering Bridge Over Roadway'''</u> | |||

|- | |||

|[[image:751.6.2.11-Typical Roadway.jpg|center|x300px]] ||style="width: 200px"| || [[image:751.6.2.11-Deck Joints Roadway.jpg|center|x300px]] | |||

|- | |||

|style="font-size:0.75em"|'''Typical Coating (System G)''' || ||style="font-size:0.75em"|'''Coating Near Deck Joints (System G)''' | |||

|- | |||

|} | |||

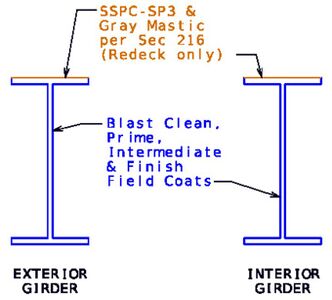

'''2. Bridges over Streams and Bridges over Railroads ''' | '''2. Bridges over Streams and Bridges over Railroads ''' | ||

| Line 1,022: | Line 1,065: | ||

The surfaces of all structural steel located under expansion joints of beam and girder spans shall be field coated with intermediate and finish coats for a distance of one and a half times the girder depth, but not less than 10 feet from the center line of the joint. Within the limit, the items to be field coated shall include all surfaces of beams, girders, bearings, diaphragms, stiffeners and miscellaneous structural steel items. Areas of steel to be in contact with concrete shall not receive the field coats. The limits of the field coatings shall be masked to provide crisp, straight lines and to prevent overspray on adjacent areas. | The surfaces of all structural steel located under expansion joints of beam and girder spans shall be field coated with intermediate and finish coats for a distance of one and a half times the girder depth, but not less than 10 feet from the center line of the joint. Within the limit, the items to be field coated shall include all surfaces of beams, girders, bearings, diaphragms, stiffeners and miscellaneous structural steel items. Areas of steel to be in contact with concrete shall not receive the field coats. The limits of the field coatings shall be masked to provide crisp, straight lines and to prevent overspray on adjacent areas. | ||

When System I is specified, the intermediate field coat will not be required. | |||

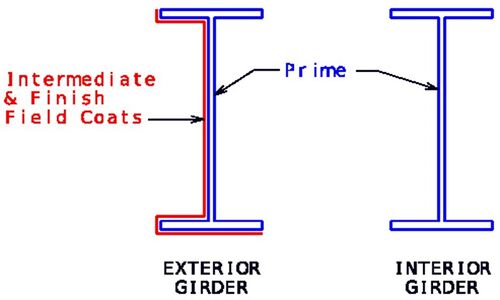

{| style="text-align: center; font-size:1.6em", align="center" | |||

|- | |||

|COLSPAN="3"|<u>'''New Non-Weathering Bridge Over Stream or Railroad'''</u> | |||

|- | |||

|[[image:751.6.2.11-Typical_Stream_RR.jpg|center|x300px]] ||style="width: 200px"| || [[image:751.6.2.11-Deck_Joints_Stream_RR.jpg|center|x300px]] | |||

|- | |||

|style="font-size:0.75em"|'''Typical Coating (System G)''' || ||style="font-size:0.75em"| '''Coating Near Deck Joints (System G)''' | |||

|- | |||

|} | |||

'''<u>Coating New Truss Bridges or Other Unusual Structures</u> ''' | '''<u>Coating New Truss Bridges or Other Unusual Structures</u> ''' | ||

| Line 1,027: | Line 1,082: | ||

Intermediate Field Coat and Finish Field Coat (System G, H or I) (Gray or brown) - The quantity shall be computed as a lump sum quantity. | Intermediate Field Coat and Finish Field Coat (System G, H or I) (Gray or brown) - The quantity shall be computed as a lump sum quantity. | ||

All structural steel for truss or steel box girder spans shall be field coated with intermediate and finish coats, except the area of steel to be in contact with concrete. | All structural steel for truss or steel box girder spans shall be field coated with intermediate and finish coats, except the area of steel to be in contact with concrete and intermediate field coat is not required when System I is specified. | ||

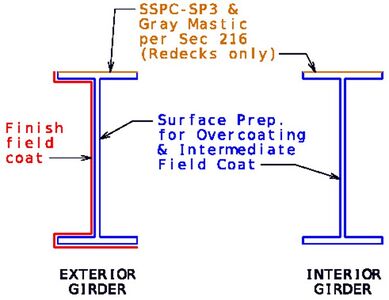

<u>'''Recoating Existing Multi-Girder/Beam Bridges '''</u> | <u>'''Recoating Existing Multi-Girder/Beam Bridges '''</u> | ||

| Line 1,033: | Line 1,088: | ||

Quantities shall be computed to the nearest one hundred square feet of structural steel to be prepared or coated. The area computations do not include bearings, diaphragms, stiffeners and all other misc. steel within the limits of surface preparation or field coatings. | Quantities shall be computed to the nearest one hundred square feet of structural steel to be prepared or coated. The area computations do not include bearings, diaphragms, stiffeners and all other misc. steel within the limits of surface preparation or field coatings. | ||

'''1. Surface Preparation for Recoating Structural Steel '''- Preparation shall include the surfaces of all structural steel. | '''1. Surface Preparation for Recoating Structural Steel '''- Preparation shall include the surfaces of all structural steel except areas to be in contact with concrete. | ||

'''2. Field Application of Inorganic Zinc Primer''' - Coverage shall meet the same requirements of Surface Preparation for Recoating Structural Steel. | '''2. Field Application of Inorganic or Organic Zinc Primer''' - Coverage shall meet the same requirements of Surface Preparation for Recoating Structural Steel. | ||

'''3. Intermediate Field Coat (System G or H) (Gray or Brown)''' - Coverage shall meet the same requirements as new multi-girder/beam bridges. | '''3. Intermediate Field Coat (System G or H) (Gray or Brown)''' - Coverage shall meet the same requirements as new multi-girder/beam bridges. | ||

'''4. Finish Field Coat (System G, H or I) (Gray or Brown)''' - Coverage shall meet the same requirements as new multi-girder/beam bridges. | '''4. Finish Field Coat (System G, H or I) (Gray or Brown)''' - Coverage shall meet the same requirements as new multi-girder/beam bridges. | ||

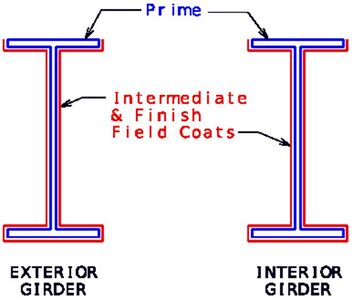

{| style="text-align: center; font-size:1.6em", align="center" | |||

|- | |||

|COLSPAN="3"|<u>'''Existing Non-Weathering Bridge'''</u> | |||

|- | |||

|[[image:751.6.2.11-Recoating_Roadway.jpg|center|x300px]] ||style="width: 200px"| || [[image:751.6.2.11-Recoating_Stream_RR.jpg|center|x300px]] | |||

|- | |||

|style="font-size:0.75em"|'''Typical Recoating Over Roadway (System G)''' || ||style="font-size:0.75em"| '''Typical Recoating Over Stream or Railroad (System G)''' | |||

|- | |||

|COLSPAN="3"|[[image:751.6.2.11-Recoating_Deck_Joints.jpg|center|x300px]] | |||

|- | |||

|COLSPAN="3" style="font-size:0.75em"|'''Recoating Near Deck Joints (System G)''' | |||

|- | |||

|} | |||

<u>'''Recoating Existing Truss Bridges or other Unusual Structures '''</u> | <u>'''Recoating Existing Truss Bridges or other Unusual Structures '''</u> | ||

| Line 1,045: | Line 1,114: | ||

Quantities shall be computed as lump sum quantities. The approximate weight of steel shall be shown to the nearest ton in the contract documents. | Quantities shall be computed as lump sum quantities. The approximate weight of steel shall be shown to the nearest ton in the contract documents. | ||

'''1. Surface Preparation for Recoating Structural Steel''' - Preparation shall include the surfaces of all structural steel. | '''1. Surface Preparation for Recoating Structural Steel''' - Preparation shall include the surfaces of all structural steel except areas to be in contact with concrete. | ||

'''2. Field Application of Inorganic Zinc Primer''' – Coverage shall meet the same requirements of Surface Preparation for Recoating Structural Steel. | '''2. Field Application of Inorganic or Organic Zinc Primer''' – Coverage shall meet the same requirements of Surface Preparation for Recoating Structural Steel. | ||

'''3. Intermediate Field Coat (System G or H) (Gray or Brown)''' – Coverage shall meet the same requirements as new truss bridges. | '''3. Intermediate Field Coat (System G or H) (Gray or Brown)''' – Coverage shall meet the same requirements as new truss bridges. | ||

| Line 1,057: | Line 1,126: | ||

Quantities shall be computed to the nearest one hundred square feet of structural steel to be prepared or overcoated except as noted below. The area computations do not include bearings, diaphragms, stiffeners and all other misc. steel within the limits of surface preparation or field coatings. Partial overcoating of steel structures is allowed and the areas of partial overcoating should be clearly indicated shown on the plans. | Quantities shall be computed to the nearest one hundred square feet of structural steel to be prepared or overcoated except as noted below. The area computations do not include bearings, diaphragms, stiffeners and all other misc. steel within the limits of surface preparation or field coatings. Partial overcoating of steel structures is allowed and the areas of partial overcoating should be clearly indicated shown on the plans. | ||

'''1. Surface Preparation for Overcoating Structural Steel''' - Preparation shall include the surfaces of all structural steel. | '''1. Surface Preparation for Overcoating Structural Steel (System G)''' - Preparation shall include the surfaces of all structural steel except areas to be in contact with concrete. | ||

'''2. | '''2. Intermediate Field Coat (System G)''' - Coverage shall meet the same requirements as Surface Preparation for Overcoating Structural Steel (System G). | ||

'''3. | '''3. Finish Field Coat (System G)''' - Coverage shall meet the same requirements as new bridges. | ||

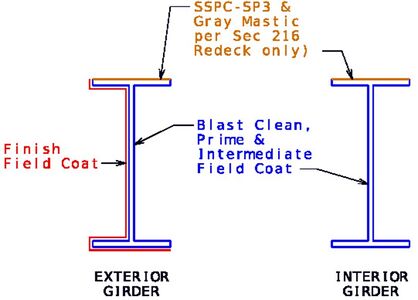

{| style="text-align: center; font-size:1.6em", align="center" | |||

|- | |||

|COLSPAN="3"|[[image:751.6.2.11-Overcoating_Existing_Bridge.jpg|center|x300px]] | |||

|- | |||

|COLSPAN="3" style="font-size:0.75em"|'''Overcoating Existing Non-Weathering Bridge (System G)''' | |||

|- | |||

|} | |||

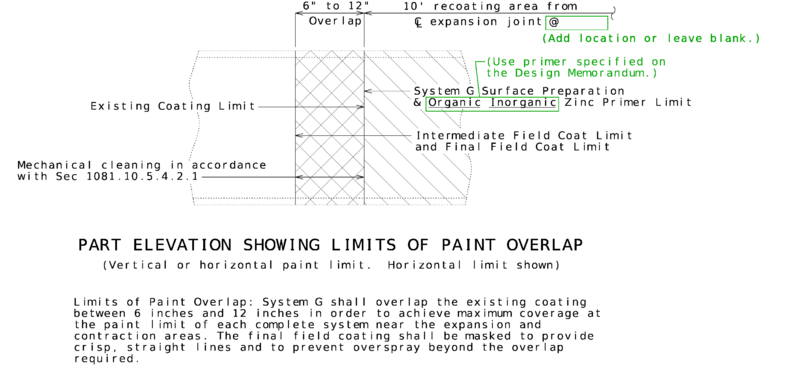

<u>'''Limits of Paint Overlap '''</u> | <u>'''Limits of Paint Overlap '''</u> | ||

Refer to [[751. | Refer to [[751.50_Standard_Detailing_Notes#A4a1._Steel_Structures-_Nonweathering_Steel|EPG 751.50 Note A4a1.24]]. The figure below with note is available in a CADD cell. | ||

[[image:Part_Elev_Paint_Overlap_11-3-23.png|800px]] | |||

| | |||

====751.6.2.12 Structural Steel Protective Coatings (Weathering Steel)==== | ====751.6.2.12 Structural Steel Protective Coatings (Weathering Steel)==== | ||

| Line 1,088: | Line 1,158: | ||

For existing multi-girder/beam bridges, quantities shall be computed to the nearest one hundred square feet of structural steel to be prepared or recoated. The area computations do not include bearings, diaphragms, stiffeners and all other misc. steel within the limits of surface preparation or field coatings. For truss bridges or other unusual structures, quantities shall be computed as lump sum quantities. | For existing multi-girder/beam bridges, quantities shall be computed to the nearest one hundred square feet of structural steel to be prepared or recoated. The area computations do not include bearings, diaphragms, stiffeners and all other misc. steel within the limits of surface preparation or field coatings. For truss bridges or other unusual structures, quantities shall be computed as lump sum quantities. | ||

'''1. Surface Preparation for Recoating Structural Steel''' - Preparation shall be on a case-by-case basis. | '''1. Surface Preparation for Recoating Structural Steel''' - Preparation shall be on a case-by-case basis except areas to be in contact with concrete. | ||

'''2. Field Application of Inorganic Zinc Primer''' - Coverage shall meet the same requirements of Surface Preparation for Recoating Structural Steel. | '''2. Field Application of Inorganic or Organic Zinc Primer''' - Coverage shall meet the same requirements of Surface Preparation for Recoating Structural Steel. | ||

'''3. Intermediate Field Coat (System | '''3. Intermediate Field Coat (System G) (Brown)''' - Coverage shall be on a case-by-case basis. | ||

'''4. Finish Field Coat (System | '''4. Finish Field Coat (System G or I) (Brown)''' - Coverage shall be on a case-by-case basis. | ||

====751.6.2.13 Protective Coatings for Concrete==== | ====751.6.2.13 Protective Coatings for Concrete==== | ||

| Line 1,124: | Line 1,194: | ||

====751.6.2.15 Seal Coat ==== | ====751.6.2.15 Seal Coat ==== | ||

A seal coat shall be used when specified on the Bridge Memo. Grade B1 seal coat aggregate shall be used whenever a bridge deck is to receive an asphalt wearing surface. Grade A1 seal coat aggregate shall be used whenever the seal coat is to be the final riding surface. Unit weights will not be calculated. | A seal coat shall be used when specified on the Bridge Memo. | ||