Category:1057 Material for Joints: Difference between revisions

No edit summary |

m →1057.2.3 Basis of Acceptance: updated link to 106.12 |

||

| (23 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

This guidance establishes procedures for inspecting, sampling, testing and reporting materials for joints. | {|style="padding: 0.3em; margin-left:1px; border:2px solid #a9a9a9; text-align:center; font-size: 95%; background:#f5f5f5" width="280px" align="right" | ||

|- | |||

|'''MGS Information''' | |||

|- | |||

|[https://www.modot.org/general-services-specifications-mgs-subject Current General Services Specifications (MGS) By Subject] | |||

|} | |||

This guidance establishes procedures for inspecting, [[106.3 Samples, Tests and Cited Specifications#106.3.1 Sampling|sampling]], testing and reporting materials for joints. Refer to [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=14 Sec 1057] for MoDOT's specifications. | |||

For Laboratory testing and sample reporting procedures, refer to [[1057.4 Laboratory Testing for Sec 1057|EPG 1057.4 Laboratory Testing Guidelines for Sec 1057]]. | |||

==1057.1 Apparatus== | ==1057.1 Apparatus== | ||

| Line 10: | Line 19: | ||

==1057.2 Procedure== | ==1057.2 Procedure== | ||

===1057.2.1 Pre-Acceptance Lists=== | ===1057.2.1 Pre-Acceptance Lists=== | ||

Manufacturers and | Manufacturers and brand names (as applicable) of dowel bars, tie bars, hot pour elastic joint sealer, performed fiber expansion joint filler, plastic waterstop, rubber waterstop, copper sheeting for flashing, preformed sponge rubber expansion joint filler, plastic joint compound for pipe, and silicone sealant for joints will be placed on the [https://www.modot.org/materials Pre-Acceptance Lists] on the MoDOT website maintained by the Central Office in accordance with [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=4 Sec 106]. These lists are found in the [http://www.modot.mo.gov/business/materials/pdf/PAL/PICK%20LIST%20OF%20PAL%20MATERIALS.pdf Material for Joints Pre-Acceptance List]. | ||

===1057.2.2 Manufacturer and Brand Name Approval=== | ===1057.2.2 Manufacturer and Brand Name Approval=== | ||

If a manufacturer desires to have material added to the Pre-Acceptance List of material for joints, a certification and guarantee must be submitted to Central Office Construction and Materials in accordance with the requirements of Specification [http://modot. | If a manufacturer desires to have material added to the Pre-Acceptance List of material for joints, a certification and guarantee must be submitted to Central Office Construction and Materials in accordance with the requirements of Specification [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=14 Sec 1057]. The certification and guarantee shall be accompanied by a sample of the material, if required by the specification, for laboratory testing. Upon approval of the material, it will be placed on the applicable list. | ||

===1057.2.3 Basis of Acceptance=== | ===1057.2.3 Basis of Acceptance=== | ||

Material is accepted by the PAL criteria as indicated in [[106. | Material is accepted by the PAL criteria as indicated in [[106.12_Qualified_Lists_(QL)_and_Pre-Acceptance_Lists_(PAL)|EPG 106.12 Qualified Lists (QL) and Pre-Acceptance Lists (PAL)]]. Central Office Construction and Materials will retain the original certification and guarantee. Additional certification is not necessary if the manufacturer and brand of material is clearly identified on the packaging or the documentation included with the shipment. | ||

===1057.2.4 Sampling=== | ===1057.2.4 Sampling=== | ||

Each producer or supplier will be assigned to a district office for Facility Review, Sampling and Testing in accordance with [[106. | Each producer or supplier will be assigned to a district office for Facility Review, Sampling and Testing in accordance with [[106.12 Pre-Acceptance Lists (PAL)|EPG 106.12 Pre-Acceptance Lists (PAL)]]. During the visit, samples of material available at the facility should be obtained. Materials selected for sampling will typically be those that have been used in MoDOT work during the past month. Material originating at locations too far from the assigned district’s office is subject to sampling at an intermediate location or at the jobsite. It is the assigned district’s responsibility to coordinate with the supplier and other districts to assure the proper materials are sampled. | ||

====1057.2.4.1 Dowel Bars==== | ====1057.2.4.1 Dowel Bars==== | ||

Dowel bars for use in dowel supporting units shall be inspected in accordance with [[:Category:1036 Reinforcing Steel for Concrete|Reinforcing Steel for Concrete]]. In addition, the inspector shall | [[image:1057.2.4.1.jpg|right|300px]] | ||

Dowel bars for use in dowel supporting units shall be inspected in accordance with [[:Category:1036 Reinforcing Steel for Concrete|Reinforcing Steel for Concrete]]. In addition, the inspector shall ensure that the bars are smooth, round, and free of cutting burrs and other projections. | |||

'''1057.2.4.1.1 Dowel Supporting Units.''' Dowel supporting units shall be inspected to | '''1057.2.4.1.1 Dowel Supporting Units.''' Dowel supporting units shall be inspected to ensure that approved bars are used to fabricate a unit meeting the requirements of [http://modot.mo.gov/business/standards_and_specs/documents/50210.pdf Standard Drawing 502.10]. | ||

'''1057.2.4.1.2 Graphite Grease.''' The free end of the dowel bar is given a coating of approved graphite grease. Graphite grease shall be applied in a manner that will result in a thorough covering of that section of the bar with a thin uniform coating. Graphite grease shall be accepted on the basis of manufacturer's certification or label analysis showing specification compliance. In many cases, this is performed in the field by the Resident Engineer. No testing or reporting is required. If the graphite grease containers do not show the necessary information and if certification cannot be obtained, samples are to be submitted to the Central Laboratory. | '''1057.2.4.1.2 Graphite Grease.''' The free end of the dowel bar is given a coating of approved graphite grease. Graphite grease shall be applied in a manner that will result in a thorough covering of that section of the bar with a thin uniform coating. Graphite grease shall be accepted on the basis of manufacturer's certification or label analysis showing specification compliance. In many cases, this is performed in the field by the Resident Engineer. No testing or reporting is required. If the graphite grease containers do not show the necessary information and if certification cannot be obtained, samples are to be submitted to the Central Laboratory. | ||

| Line 37: | Line 47: | ||

====1057.2.4.4 Preformed Fiber Expansion Joint Filler==== | ====1057.2.4.4 Preformed Fiber Expansion Joint Filler==== | ||

A sample shall consist of one piece, a minimum of 6 x 24 in. (150 x 600 mm). When the material is furnished in strips and the full sheet is not available for sampling, the sample width may be reduced from 6 in. (150 mm) to the width of the strip or a minimum of 4-1/2 in. (115 mm). For lesser widths, the material may be accepted by a manufacturer's certification to AASHTO M 213. | A sample shall consist of one piece, a minimum of 6 in. x 24 in. (150 mm x 600 mm). When the material is furnished in strips and the full sheet is not available for sampling, the sample width may be reduced from 6 in. (150 mm) to the width of the strip or a minimum of 4-1/2 in. (115 mm). For lesser widths, the material may be accepted by a manufacturer's certification to AASHTO M 213. | ||

====1057.2.4.5 Plastic Waterstop==== | ====1057.2.4.5 Plastic Waterstop==== | ||

| Line 45: | Line 55: | ||

A sample shall consist of two pieces, a minimum of 3 ft. (915 mm) long. | A sample shall consist of two pieces, a minimum of 3 ft. (915 mm) long. | ||

{| style="margin: 1em auto 1em auto" align="right" | |||

|- | |||

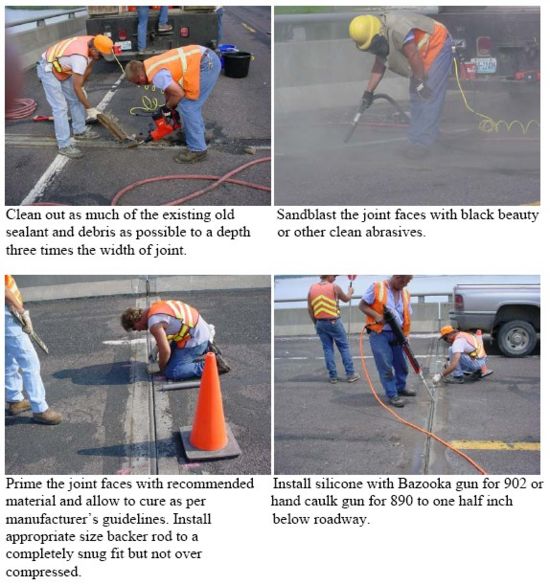

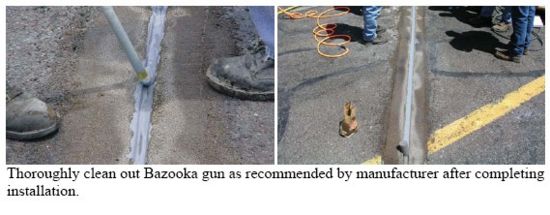

|+'''Bridge Joint Sealing - Silicone''' | |||

|[[image:1057a.jpg|right|550px]] | |||

|- | |||

|[[image:1057b.jpg|right|550px]] | |||

|} | |||

====1057.2.4.7 Copper Sheeting for Flashing==== | ====1057.2.4.7 Copper Sheeting for Flashing==== | ||

A sample shall consist of one piece, a minimum of 6 x 12 in. (150 x 300 mm). | A sample shall consist of one piece, a minimum of 6 in. x 12 in. (150 mm x 300 mm). | ||

====1057.2.4.8 Preformed Sponge Rubber Compound Expansion and Partition Joint Filler==== | ====1057.2.4.8 Preformed Sponge Rubber Compound Expansion and Partition Joint Filler==== | ||

A sample shall consist of one piece, a minimum of 6 x 12 in. (150 x 300 mm). | A sample shall consist of one piece, a minimum of 6 in. x 12 in. (150 mm x 300 mm). | ||

====1057.2.4.9 Plastic Joint Compound for Vitrified Clay and Concrete Pipe==== | ====1057.2.4.9 Plastic Joint Compound for Vitrified Clay and Concrete Pipe==== | ||

A sample of trowel grade, bulk type compound shall consist of approximately one gallon (4 liters) of material in a friction top can. A sample of extruded rope or flat tape shall consist of approximately 0.5 lb (230 g) of material in a friction top can or other suitable airtight container. Primer, if required to be used with extruded rope or flat tape types to maintain the material in position while pipe sections are being joined, shall be checked to | A sample of trowel grade, bulk type compound shall consist of approximately one gallon (4 liters) of material in a friction top can. A sample of extruded rope or flat tape shall consist of approximately 0.5 lb (230 g) of material in a friction top can or other suitable airtight container. Primer, if required to be used with extruded rope or flat tape types to maintain the material in position while pipe sections are being joined, shall be checked to ensure that it has been recommended by the manufacturer of the joint material. | ||

====1057.2.4.10 Silicone Expansion Joint Sealant==== | ====1057.2.4.10 Silicone Expansion Joint Sealant==== | ||

| Line 65: | Line 82: | ||

==1057.3 Report (Records)== | ==1057.3 Report (Records)== | ||

===1057.3.1 Samples=== | ===1057.3.1 Samples=== | ||

Samples shall be recorded using | Samples shall be recorded using AASHTOWARE Project (AWP) showing the manufacturer’s name, the brand name (as applicable), lot or heat number, net quantity represented, and the location where the sample was obtained using the Sampled From and Sample Origin fields of AWP. If the material is sampled after having a PAL ID assigned to it, the “Link To” field should be used to link the two sample records in AWP. Test results on random samples of material will be reported by the Central Laboratory. | ||

===1057.3.2 Supplier Notification=== | ===1057.3.2 Supplier Notification=== | ||

For material shipped directly to the jobsite by a supplier, the supplier shall notify Central Office Construction and Materials prior to shipment using Form 3 | For material shipped directly to the jobsite by a supplier, the supplier shall notify Central Office Construction and Materials prior to shipment using [http://www.modot.mo.gov/business/materials/pdf/vol_1/GS013F3.pdf Form 3]. When complete and correct information on the shipment is provided to Central Office Construction and Materials, a PAL ID number will be assigned to the material. That number shall accompany the material in shipment and be immediately available until the material is consumed. | ||

===1057.3.3 Material Purchased for Maintenance=== | ===1057.3.3 Material Purchased for Maintenance=== | ||

Material purchased for maintenance work will be accepted in accordance with | Material purchased for maintenance work will be accepted in accordance with [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=14 Sec 1057.2]. | ||

Latest revision as of 09:29, 13 December 2024

| MGS Information |

| Current General Services Specifications (MGS) By Subject |

This guidance establishes procedures for inspecting, sampling, testing and reporting materials for joints. Refer to Sec 1057 for MoDOT's specifications.

For Laboratory testing and sample reporting procedures, refer to EPG 1057.4 Laboratory Testing Guidelines for Sec 1057.

1057.1 Apparatus

- (a) Rule with suitable graduations to accurately measure the material to be inspected.

- (b) Micrometer or vernier caliper capable of measuring to 0.0001 in. (0.00254 mm) and accurate to within at least 0.001 in. (0.0254 mm).

- (c) Balance or scale accurate to within 0.5 percent of the weight (mass) of the sample to be weighed.

1057.2 Procedure

1057.2.1 Pre-Acceptance Lists

Manufacturers and brand names (as applicable) of dowel bars, tie bars, hot pour elastic joint sealer, performed fiber expansion joint filler, plastic waterstop, rubber waterstop, copper sheeting for flashing, preformed sponge rubber expansion joint filler, plastic joint compound for pipe, and silicone sealant for joints will be placed on the Pre-Acceptance Lists on the MoDOT website maintained by the Central Office in accordance with Sec 106. These lists are found in the Material for Joints Pre-Acceptance List.

1057.2.2 Manufacturer and Brand Name Approval

If a manufacturer desires to have material added to the Pre-Acceptance List of material for joints, a certification and guarantee must be submitted to Central Office Construction and Materials in accordance with the requirements of Specification Sec 1057. The certification and guarantee shall be accompanied by a sample of the material, if required by the specification, for laboratory testing. Upon approval of the material, it will be placed on the applicable list.

1057.2.3 Basis of Acceptance

Material is accepted by the PAL criteria as indicated in EPG 106.12 Qualified Lists (QL) and Pre-Acceptance Lists (PAL). Central Office Construction and Materials will retain the original certification and guarantee. Additional certification is not necessary if the manufacturer and brand of material is clearly identified on the packaging or the documentation included with the shipment.

1057.2.4 Sampling

Each producer or supplier will be assigned to a district office for Facility Review, Sampling and Testing in accordance with EPG 106.12 Pre-Acceptance Lists (PAL). During the visit, samples of material available at the facility should be obtained. Materials selected for sampling will typically be those that have been used in MoDOT work during the past month. Material originating at locations too far from the assigned district’s office is subject to sampling at an intermediate location or at the jobsite. It is the assigned district’s responsibility to coordinate with the supplier and other districts to assure the proper materials are sampled.

1057.2.4.1 Dowel Bars

Dowel bars for use in dowel supporting units shall be inspected in accordance with Reinforcing Steel for Concrete. In addition, the inspector shall ensure that the bars are smooth, round, and free of cutting burrs and other projections.

1057.2.4.1.1 Dowel Supporting Units. Dowel supporting units shall be inspected to ensure that approved bars are used to fabricate a unit meeting the requirements of Standard Drawing 502.10.

1057.2.4.1.2 Graphite Grease. The free end of the dowel bar is given a coating of approved graphite grease. Graphite grease shall be applied in a manner that will result in a thorough covering of that section of the bar with a thin uniform coating. Graphite grease shall be accepted on the basis of manufacturer's certification or label analysis showing specification compliance. In many cases, this is performed in the field by the Resident Engineer. No testing or reporting is required. If the graphite grease containers do not show the necessary information and if certification cannot be obtained, samples are to be submitted to the Central Laboratory.

1057.2.4.1.3 Bondbreaker. An approved bondbreaker solution may be used to coat completed dowel bar basket units as an alternative to coating dowel bars with graphite grease. The units shall be pre-dipped and the bondbreaker should not be sprayed or field applied. The bondbreaker should be uniformly applied without excessive drips or thickness. Excessive dripping or thickness shall be cause for rejection. The bondbreaker shall be applied following manufacturer recommendations. Certification for the bondbreaker, showing the product name, manufacturer, and date of coating application, shall be provided by the dowel basket supplier.

1057.2.4.2 Tie Bars

Tie bars shall be round deformed steel reinforcing bars inspected in accordance with Reinforcing Steel for Concrete except that tie bars which are to be bent and straightened shall be Grade 40 (300) in accordance with AASHTO M 31.

1057.2.4.3 Concrete Joint Sealer, Hot Poured Elastic Type

A sample shall consist of the bulk container or one of the packaged parts of the bulk container (in the original manufacturer's container). A sample can also consist of a minimum of one gallon (4 liters) of material taken from the bulk container in a friction top container.

1057.2.4.4 Preformed Fiber Expansion Joint Filler

A sample shall consist of one piece, a minimum of 6 in. x 24 in. (150 mm x 600 mm). When the material is furnished in strips and the full sheet is not available for sampling, the sample width may be reduced from 6 in. (150 mm) to the width of the strip or a minimum of 4-1/2 in. (115 mm). For lesser widths, the material may be accepted by a manufacturer's certification to AASHTO M 213.

1057.2.4.5 Plastic Waterstop

A sample shall consist of two pieces, a minimum of 3 ft. (915 mm) long.

1057.2.4.6 Rubber Waterstop

A sample shall consist of two pieces, a minimum of 3 ft. (915 mm) long.

|

|

1057.2.4.7 Copper Sheeting for Flashing

A sample shall consist of one piece, a minimum of 6 in. x 12 in. (150 mm x 300 mm).

1057.2.4.8 Preformed Sponge Rubber Compound Expansion and Partition Joint Filler

A sample shall consist of one piece, a minimum of 6 in. x 12 in. (150 mm x 300 mm).

1057.2.4.9 Plastic Joint Compound for Vitrified Clay and Concrete Pipe

A sample of trowel grade, bulk type compound shall consist of approximately one gallon (4 liters) of material in a friction top can. A sample of extruded rope or flat tape shall consist of approximately 0.5 lb (230 g) of material in a friction top can or other suitable airtight container. Primer, if required to be used with extruded rope or flat tape types to maintain the material in position while pipe sections are being joined, shall be checked to ensure that it has been recommended by the manufacturer of the joint material.

1057.2.4.10 Silicone Expansion Joint Sealant

A sample shall consist of two sets of tubes with 4 blending tips.

1057.2.4.11 Silicone Joint Sealant for Saw Cut and Formed Joints

A sample shall consist of two sets of tubes with 4 blending tips.

1057.2.4.12 Backer Rod

Backer rods shall be closed-cell as recommended by the silicone sealant manufacturer or shall be in accordance with ASTM D 5249, Type 3. A manufacturer’s certification will be provided by the contractor. No sampling or testing is necessary.

1057.3 Report (Records)

1057.3.1 Samples

Samples shall be recorded using AASHTOWARE Project (AWP) showing the manufacturer’s name, the brand name (as applicable), lot or heat number, net quantity represented, and the location where the sample was obtained using the Sampled From and Sample Origin fields of AWP. If the material is sampled after having a PAL ID assigned to it, the “Link To” field should be used to link the two sample records in AWP. Test results on random samples of material will be reported by the Central Laboratory.

1057.3.2 Supplier Notification

For material shipped directly to the jobsite by a supplier, the supplier shall notify Central Office Construction and Materials prior to shipment using Form 3. When complete and correct information on the shipment is provided to Central Office Construction and Materials, a PAL ID number will be assigned to the material. That number shall accompany the material in shipment and be immediately available until the material is consumed.

1057.3.3 Material Purchased for Maintenance

Material purchased for maintenance work will be accepted in accordance with Sec 1057.2.

Articles in "1057 Material for Joints"

This category contains only the following page.