Category:704 Concrete Masonry Repair: Difference between revisions

No edit summary |

m →704.2 Materials Inspection for Sec 704: updated JSP link |

||

| (16 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{|style="padding: 0.3em; margin-left:15px; border:1px solid #a9a9a9; text-align:center; font-size: 95%; background:#f5f5f5" width="160px" align="right" | |||

|- | |||

|'''Approved Products''' | |||

|- | |||

|[https://www.modot.org/media/464 Qualified Rapid Set Concrete Patching Material (Horizontal)] | |||

|- | |||

|[https://www.modot.org/media/18503 Qualified Rapid Set Concrete Patching Material (Vertical and Overhead)] | |||

|} | |||

==704.1 Construction Inspection for Sec 704== | ==704.1 Construction Inspection for Sec 704== | ||

This work consists of removing deteriorated concrete, preparing the repair site, forming | This work consists of removing deteriorated concrete, preparing the repair site, forming | ||

| Line 5: | Line 14: | ||

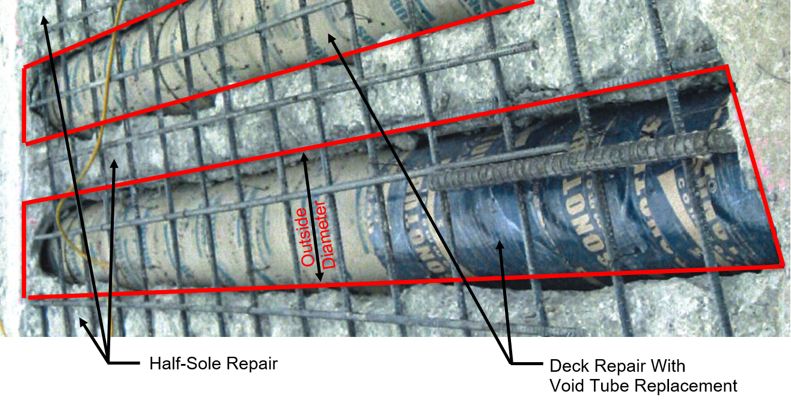

The types of repair are: | The types of repair are: | ||

* | *Half-Sole Repair | ||

*Deck Repair With Void Tube Replacement | *Deck Repair With Void Tube Replacement | ||

[[image:704.1 half sole.jpg|center|800px]] | |||

[[image:704.1 exposed.jpg|right|200px]] | |||

::If the contractor can adequately patch an exposed void tube, then the entire repair is considered either half-sole or monolithic deck repair. | |||

*Full Depth Repair | *Full Depth Repair | ||

*Modified Deck Repair | *Modified Deck Repair | ||

| Line 13: | Line 26: | ||

*Substructure Repair (Formed) | *Substructure Repair (Formed) | ||

*Substructure Repair (Unformed) | *Substructure Repair (Unformed) | ||

*Epoxy Sealing. | *Epoxy Sealing | ||

*Monolithic Deck Repair | |||

*Shallow Deck Repair | |||

Refer to [http://www.modot.org/business/standards_and_specs/SpecbookEPG.pdf#page=11 Sec 704]. | |||

Excavator hydraulic hammers shall not be used for removal of deck concrete unless otherwise specified on the bridge plans. | |||

==704.2 Materials Inspection for Sec 704== | ==704.2 Materials Inspection for Sec 704== | ||

For more information regarding Rapid Set Concrete Patching Material, refer to | For more information regarding Rapid Set Concrete Patching Material, refer to [https://epg.modot.org/forms/JSP/JSP0201.docx JSP-02-01]. | ||

Two lists of qualified rapid set concrete patching materials are maintained by Construction Materials. One list shows [https://www.modot.org/media/464 approved horizontal patching materials] and the other list is for [https://www.modot.org/media/18503 vertical and overhead patching materials]. | |||

==704.3 Laboratory Testing for Sec 704== | ==704.3 Laboratory Testing for Sec 704== | ||

| Line 28: | Line 45: | ||

===704.3.2 Procedure=== | ===704.3.2 Procedure=== | ||

Concrete cylinders shall be tested for compressive strength according to AASHTO T 22. Test results and calculations shall be recorded through | Concrete cylinders shall be tested for compressive strength according to AASHTO T 22. Test results and calculations shall be recorded through AASHTOWARE Project (AWP). | ||

===704.3.3 Sample Record=== | ===704.3.3 Sample Record=== | ||

The sample record shall be completed in | The sample record shall be completed in AASHTOWARE Project (AWP), as described in [[:Category:101 Standard Forms#Sample Record, General|AWP MA Sample Record, General]]. Appropriate remarks, as described in [[106.20 Reporting|EPG 106.20 Reporting]], are to be included in the remarks to clarify conditions of acceptance or rejection. Test results shall be reported on the appropriate templates under the Tests tab. | ||

Latest revision as of 09:29, 3 March 2023

| Approved Products |

| Qualified Rapid Set Concrete Patching Material (Horizontal) |

| Qualified Rapid Set Concrete Patching Material (Vertical and Overhead) |

704.1 Construction Inspection for Sec 704

This work consists of removing deteriorated concrete, preparing the repair site, forming where required, placing and finishing new concrete or qualified special mortar and applying epoxy in the required areas.

The types of repair are:

- Half-Sole Repair

- Deck Repair With Void Tube Replacement

- If the contractor can adequately patch an exposed void tube, then the entire repair is considered either half-sole or monolithic deck repair.

- Full Depth Repair

- Modified Deck Repair

- Superstructure Repair (Unformed)

- Slab Edge Repair

- Substructure Repair (Formed)

- Substructure Repair (Unformed)

- Epoxy Sealing

- Monolithic Deck Repair

- Shallow Deck Repair

Refer to Sec 704.

Excavator hydraulic hammers shall not be used for removal of deck concrete unless otherwise specified on the bridge plans.

704.2 Materials Inspection for Sec 704

For more information regarding Rapid Set Concrete Patching Material, refer to JSP-02-01.

Two lists of qualified rapid set concrete patching materials are maintained by Construction Materials. One list shows approved horizontal patching materials and the other list is for vertical and overhead patching materials.

704.3 Laboratory Testing for Sec 704

704.3.1 Scope

This guidance establishes procedures for Laboratory testing and reporting concrete cylinders representing Class X Concrete.

704.3.2 Procedure

Concrete cylinders shall be tested for compressive strength according to AASHTO T 22. Test results and calculations shall be recorded through AASHTOWARE Project (AWP).

704.3.3 Sample Record

The sample record shall be completed in AASHTOWARE Project (AWP), as described in AWP MA Sample Record, General. Appropriate remarks, as described in EPG 106.20 Reporting, are to be included in the remarks to clarify conditions of acceptance or rejection. Test results shall be reported on the appropriate templates under the Tests tab.